Mike Self

.

December 06, 2021

.

All Feature Vehicles

Mike Self

.

December 06, 2021

.

All Feature Vehicles

Chris has built quite a few custom rides for himself and clients, but one that he had always wanted to tackle was a late-’60s Chevy truck. He finally got his chance when he picked up a 1968 C10, but it would take more than three years to complete. After all, you can’t rush perfection!

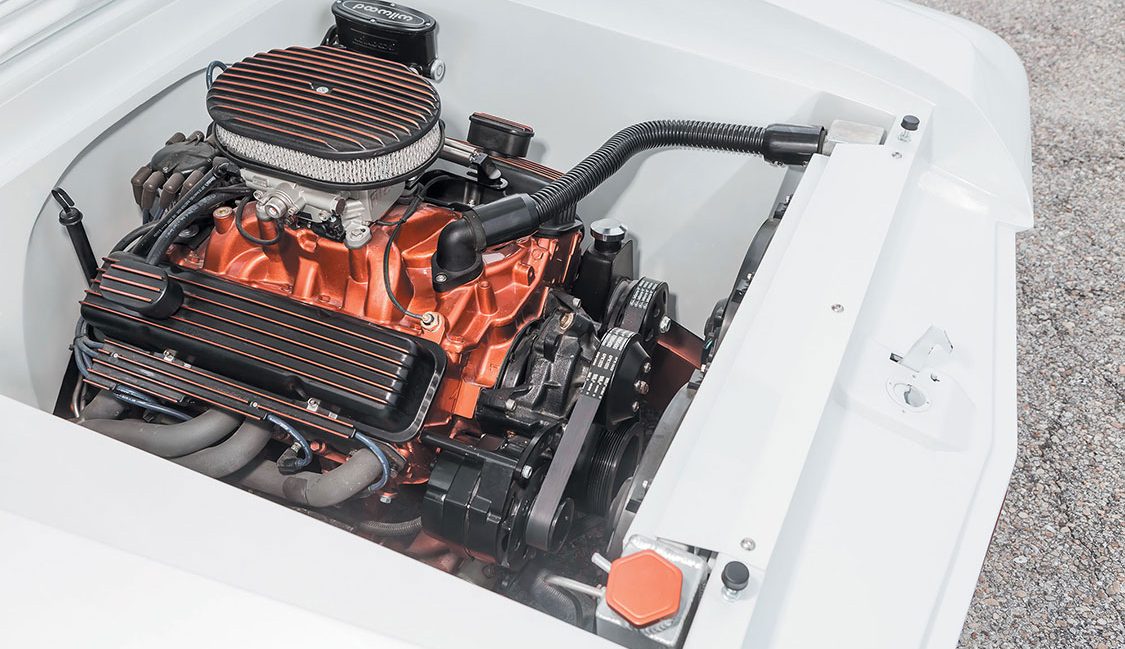

The GM Snow White three-stage pearl paintjob by Alamo Custom really accentuates the second-gen C10’s beautiful lines, but you can’t just ignore all of the work hidden underneath. Pretty much anything that protruded from the body was shaved off, front and rear roll pans were grafted on, and both the inside of the bed and engine compartment were completely reworked with some amazing sheetmetal magic. But there’s more—a lot more.

To give you a more thorough idea of the type of work that went into the body, we’ll let Chris finish explaining it himself.

“Every possible pinch weld and seam has been completely welded up, removed and smoothed out,” he says. “The entire front end and cab have been welded together to form a single assembly. The entire bed received the same treatment with a custom sheetmetal floor. The hood was sectioned and narrowed, and the leftover outer material was added to the front fenders.”

Yeah, he totally explained it better!

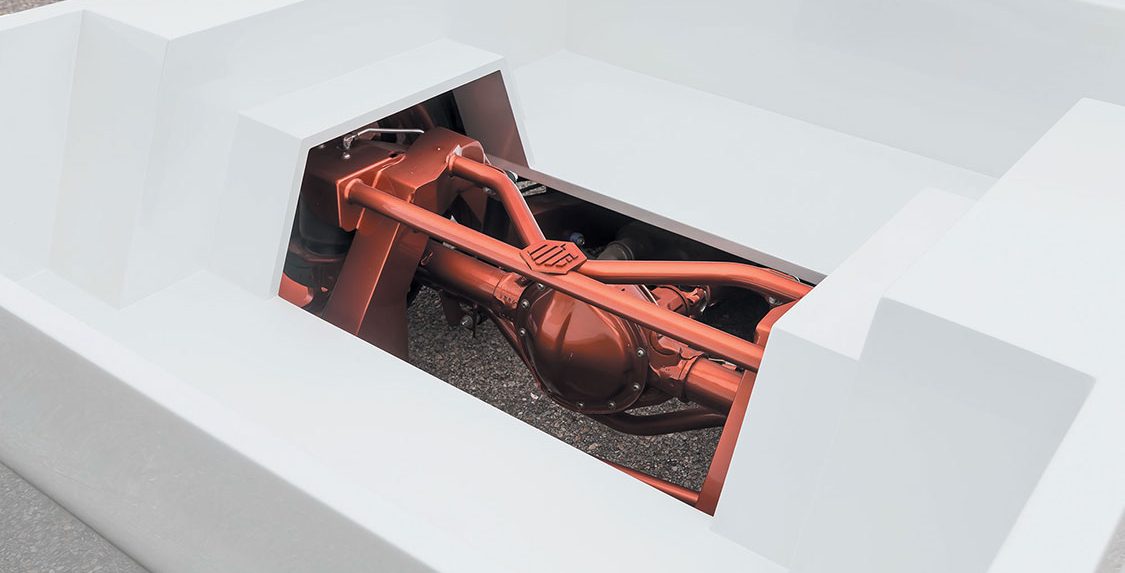

The chassis is every bit as wild, with Porterbuilt front and rear “dropmember” Stage 3 air suspension setups added onto the factory framerails for an asphalt-hugging stance, and then coated with copper paint for maximum contrast. The rearend was narrowed and beefed up to better handle the higher output of the fresh 383 stroker engine, which was dressed with a Holley intake manifold, FiTech fuel injection and Hooker headers and mated to a 4L60E transmission. Wilwood and CPP brake components were bolted on front and rear for added confidence when flooring the “go” pedal, and they look pretty dang tasty behind the copper 22×9 and 22×12 Intro Classic wheels as well.

We guess that when you do it for a living and you love what you do, it just goes with the territory!

As for the interior, that’s where Chris and his team at MTI Interiors really got to shine. Building around the custom-made bucket seats that were fitted with Relicate leather, the inner confines of Chris’ truck are nothing short of amazing. Again, it makes the most sense to let Chris describe exactly what’s going on.

“The interior was completely modeled in AutoCAD and Fusion 360, and was machined using our in-house CNC machines,” he says. “[The] techs responsible for executing the build are Matt Vowell, Edgar Diosdado, Matt Thomas, Lance Coffman, with me as the lead.”

Classic Industries instrumentation was used in the custom dash, but instead of using a ’67-’72 cluster set, a ’55-’59 Chevy truck setup was fabbed into the center of the dashboard and looks right at home. An Arc Audio stereo system was strategically placed throughout the cab, adding yet another dimension to the already insane interior.

But like we said, Chris is a bit of a perfectionist, so at the time of this writing he was already tearing apart the inside of the truck to completely redo it. We guess that when you do it for a living and you love what you do, it just goes with the territory!

View Chevy vehicle profiles here.

Share Link