Chris Hamilton

.

February 11, 2022

.

OBS Builders Guide

Chris Hamilton

.

February 11, 2022

.

OBS Builders Guide

To catch you all back up on Project OBScene, we started with a clean 304,000-mile 1997 Silverado C1500 truck. The original 305 was still running great; it was just leaking a little oil and a whole lot of power. It took Joe Egizio around two years of stalking the previous owner to finally convince him to sell the truck. The truck was immaculate thanks to the original owner being a professional detailer, it just needed some modern upgrades to make it new again.

First on the list of upgrades was a new coilover suspension from QA1. It finally handled like a rail car but lacked the power to really test out the engineering. Yes, we could upgrade the factory 350ci engine to gain a few hundred horsepower, but the time, dollars and effort spent doing that would be on par with a complete LS engine swap. So, a used 6.0-liter engine and 4L80 transmission from a 2003 Silverado with just over 100K miles was purchased.

Before installing the engine, Joe made a few important and exciting upgrades. The original heads and bottom-end block were not touched, but a Brian Tooley blower cam kit, some new LS9 head gaskets, a Melling oil pump and new timing chain were installed. ARP provided some amazing head bolts, and he also used the company’s stainless header bolt kit. A Holley 302-1 oil pan, BRP Hotrods engine and trans mounts and ceramic coated on black Hedman Hustlers to match the sexiness of the wrinkle finished Procharger. Oh, did I forget to mention we supercharged this truck?

This P-1SC-1 supercharger system from ProCharger is self-contained (SC) and the only gear-driven centrifugal supercharger to feature self-lubrication. A Current Performance wiring harness will make it plug and play with our 6.0-liter LS and Red Line fluids pump though this truck’s veins. The final step in the process was to have it tuned by Jeff’s Tuning Performance in Ocala, Florida. After a few clicks, changes and uploads, OBScene made 540 hp at the rear wheels and 503 lb-ft of torque running 6-7 pounds of boost on 93-octane fuel. It’s a truck enthusiast’s truck that everyone should hear and drive. Let’s get into some details.

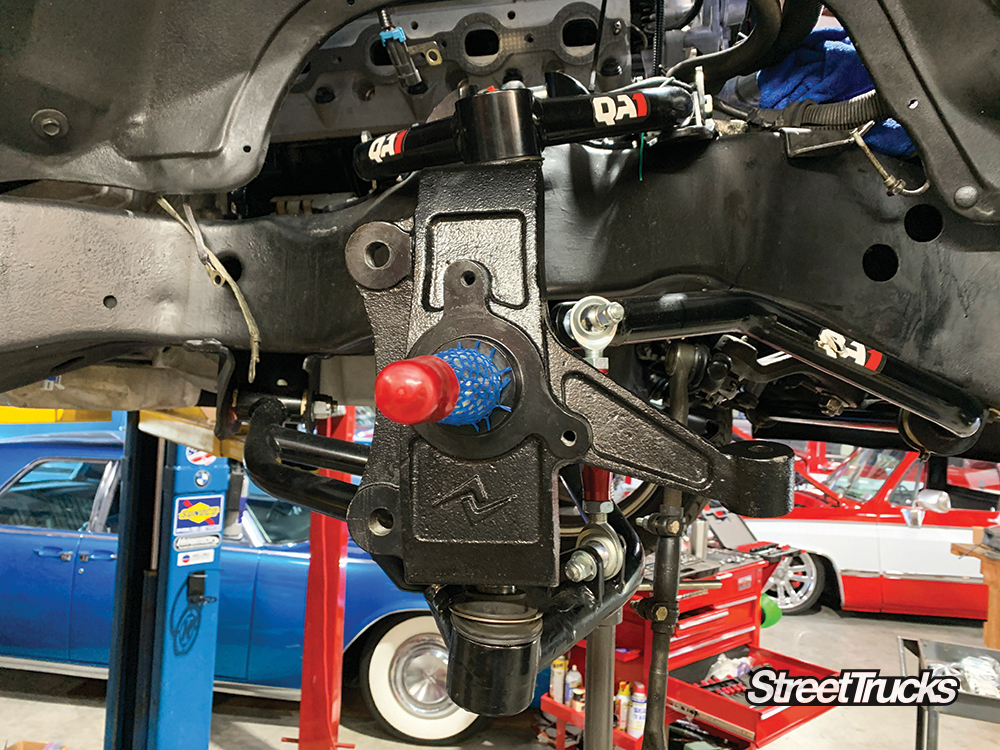

01. We started by installing a new QA1 coilover kit on this super clean, 304,000-mile OBS truck. The original 305 was still running great; it was just leaking a little oil and a whole lot of power.

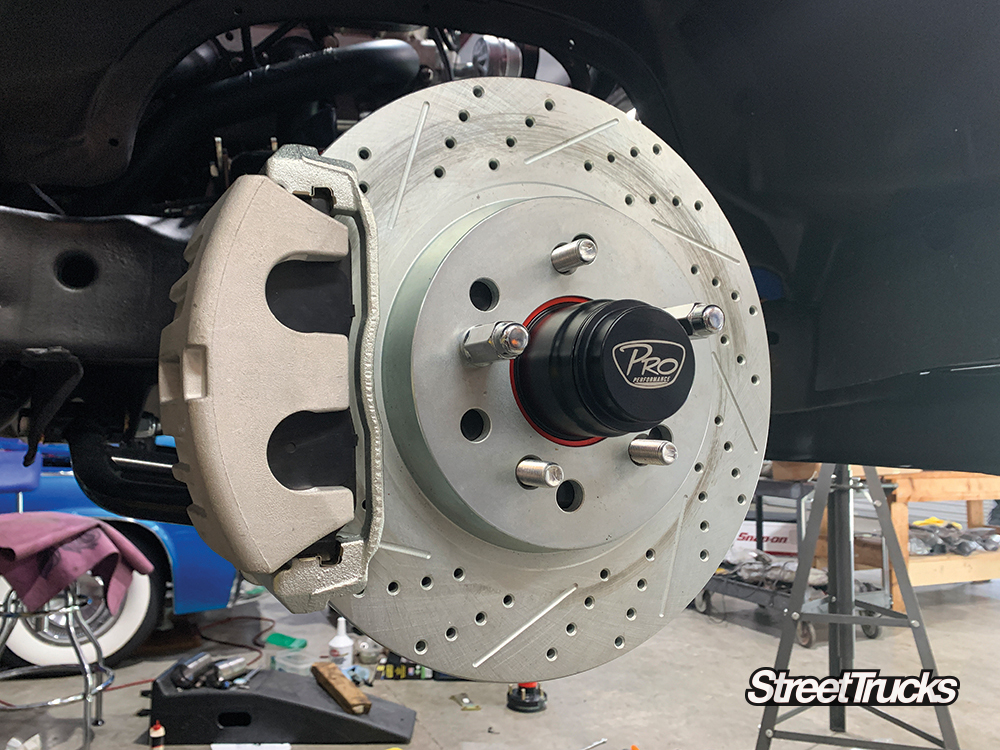

02. To handle the power we are about to give it, Joe installed an AZ Pro Performance big disc-brake conversion kit.

03. He also used the React modular drop spindles, which are engineered for these brakes.

04. The brakes are awesome, and they came with everything needed including new braided brake hoses.

05. To firm up the pedal, Joe ditched the factory master cylinder and upgraded to a NBS master cylinder out of an ’02 Silverado 1500. This gets rid of the mushy brake pedal often associated with these OBS trucks and is completely bolt on.

06. The rear suspension setup is a thing of beauty thanks to the engineers at QA1.

07. The factory drum brakes were completely removed and luckily for Joe, the axle shafts did not need to be removed for this conversion.

08. Joe was able to install the brackets on both sides quickly and easily.

09. This kit from Pro Performance is very impressive and we can’t wait to test them out.

10. American Racing VN 338 20×10 and 20×8.5 wheels wrapped in 275/40/20 and 245/40/20 tires finish off all four corners.

11. A used 6.0-liter engine and 4L80 transmission from a 2003 Silverado with just over 100K miles was purchased, before installing a Brian Tooley blower cam kit, some new LS9 head gaskets, ARP head bolts and stainless header bolt kit, a Holley 302-1 oil pan, BRP Hotrods engine mounts and ceramic coated on black Hedman Hustlers headers. A P-1SC-1 supercharger system from ProCharger is the cherry on top.

12. The Procharger used all the factory truck brackets, which made mounting the unit easy. Everything needed was provided, including a new crank pulley and pinning kit.

13. The ProCharger intercooler mounts horizontally to keep the factory A/C condenser. ProCharger also sent a ton of piping and fittings to mount the intercooler and Joe had a good friend fabricate this light but strong bracket.

14. To transfer this power we need more than the stock driveshaft. So, a new all carbon fiber unit was ordered up from QA1 and installed in Joe’s garage.

15. Before we installed it, we wanted to know just how much weight we were saving. So Joe stood on the scale and weighed both. Around an 8-pound savings in weight!

It’s a truck enthusiast’s truck that everyone should hear and drive.

16. This blue carbon fiber driveshaft from QA1 looks great installed.

17. Before installing the new modern transmission, Joe had the 4l80 rebuilt locally by Bobby in Belleview, Florida, while Joe headed out to pick up a FTI billet triple disc torque converter. As with most of our builds, Red Line fluids pump through the veins.

18. An Aeromotive Phantom flex fuel pump was also necessary along with the company’s bladder and baffle system. Braided fuel lines and fittings were also provided with the filter, regulator and pressure gauge.

19. “Special thanks to my buddies David Bennett, Jantzen and Rich up at RCS Performance in Belleview for helping with a few fab items like making a custom downpipe and brackets for the intercooler, as well as doing the exhaust work.”

20. The final step in the process was to have it tuned by Jeff’s Tuning Performance in Ocala, Florida. After a few clicks, changes and uploads, OBScene made 540 hp at the rear wheels and 503 lb-ft of torque running 6-7 pounds of boost on 93-octane fuel.

21. Joe is an average guy at heart with some above average experiences. But we all have to start somewhere, and now we all know the possibilities.

Notifications

Share Link