Jason Sands Jason Sands

.

August 18, 2023

.

Chevrolet

Jason Sands Jason Sands

.

August 18, 2023

.

Chevrolet

There’s something to be said for building a truck just the way you want it and just for yourself. Aaron Brose of Chico, California, had always been a fan of drag trucks, especially regular cab shortbeds. There was just one problem. Chevy never made one offered with a diesel engine! As it turns out, that wasn’t a problem if you’re willing to tackle a three-year project like Aaron has done.

“When I got my ‘01 Chevy, I already had in mind a low-slung regular cab shortbed drag truck,” says Aaron.

While that was fine and dandy, what he had in front of him was a stock-height longbed truck. After the longbed was long gone, the truck was shortened by 14 inches in the middle and 4 additional inches were taken out of the back to get the shortbed to fit right. A roll-pan was also installed, and the truck received a brand new grille, bumpers, and a beautiful coat of Summit White by RT’s Autobody out of Gridley, California.

At this same time, Aaron decided to make a number of suspension modifications that would help out his drag race efforts. The truck was lowered in the rear and fitted with a set of 1500-series leaf springs to compensate for the lighter bed weight. Since Aaron had his sights set on the dragstrip, the frontend of the truck received a ton of effort both for stance and strength purposes. First, the truck was slammed with a set of 3-inch lowering spindles, along with Cognito control arms, and a Kryptonite sway bar. PPE tie rods and a Dirty Hooker Diesel center support were also added, as well as a set of adjustable QA1 coilover shocks. Aaron handled this part of the build at his own shop, United Tires and Wheels in Chico, California.

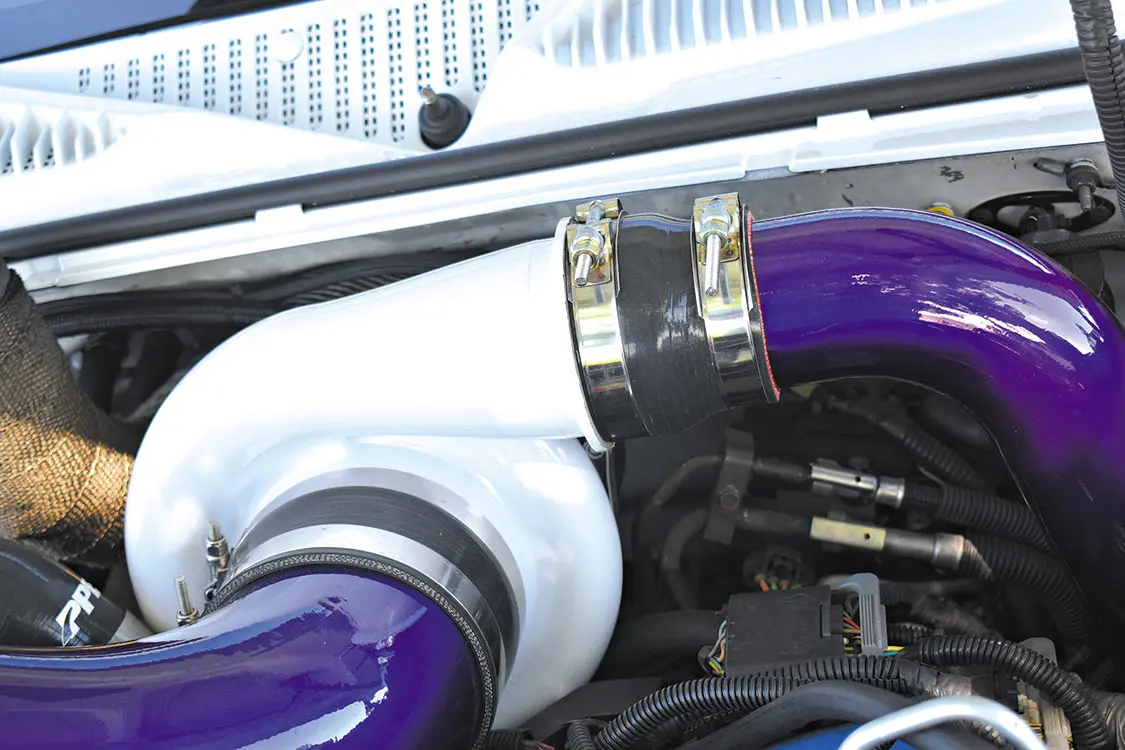

With the truck set up the way he wanted, now Aaron’s attention turned to horsepower. A lot of horsepower. This meant contacting DSS out of Modesto, California, for a blueprint for a 900 rwhp engine. To our surprise, the bottom-end of the LB7 Duramax was left stock, although it did receive a fresh set of gaskets, including head gaskets. The air and fuel sides are what really wake up diesels, and here Aaron didn’t skimp at all. The turbocharger is a massive S400-frame 75mm thumper from Smeding Diesel, and the fueling is handled by 200% over injectors from LDS, and twin 10mm pumps from Industrial Injection. There’s also higher-flowing exhaust manifolds from Maxflow Diesel, a PPE rail plug, and other odds and ends that help make the number. Aaron’s tuning is handled by Manel Vierra, who has an EFILive-tuned 10-second Duramax of his own.

The last big hurdle before the truck could pound some pavement was putting the ponies to the ground, and again, DSS was there to help with one of its Stage 5 transmissions. The Allison is rated for 1,200 horsepower and features a revised valvebody strategy, Alto clutches (with clutches added) and a Goerend triple-disc torque converter and deep transmission pan. A custom driveshaft (shortbed, remember?) was built by E.O. Design and Fabrication out of Chico, California, and the final touch as the tires touched the pavement was a set of 17-inch Weld Cheyennes, with 305/45R17 Nitto NT555 tires.

Now that he’s built the drag truck he’s always wanted, what were Aaron’s goals. Well, it seems that Aaron is a fan of round numbers, as 10-second passes and 1,000 rwhp (with a bit of nitrous) is what he’s after. “This is my first really fast vehicle, car, truck, or otherwise,” says Aaron, “so I’m getting used to the power and learning how to launch it.”

With DSS’ sister truck (same setup) making 1,029 rwhp on a Superflow dyno, we’d say Aaron is well on his way to achieving his drag truck dreams with the shortbed he’s always wanted. Aaron’s Chevy relies on the tried and true 6.6L Duramax diesel to make an estimated 900 rwhp without nitrous.

Share Link