John Mata Jr.

.

March 28, 2025

.

C10 Builders Guide

John Mata Jr.

.

March 28, 2025

.

C10 Builders Guide

All it takes is a dream to get started on something big. Turning that dream into a reality, however, requires copious amounts of blood, sweat, and tears—and sometimes a little extra cash doesn’t hurt. Building any type of custom vehicle isn’t cheap, especially when you reach way up high for top-shelf results. This includes the purchasing all the parts involved, as well as finding the right group of talented craftspeople to assist in shaping your vision.

Cesar Tijerina of San Juan, Texas, is a constant dreamer, and he has familiarized himself with how to make each new automotive fantasy of his come to life. Cesar isn’t new to the world of custom autos, and he already has a list of completed show trucks to his credit, but that doesn’t stop his mind from wandering about what he could work on next.

While he has completed a handful of custom pickups in the past, he has yet to find a 1968 model truck that he was able to put his spin on. Cesar has sharpened his skills when it comes to searching out and capturing the vehicles he wants, and he was soon in possession of a ’68 C10 that would serve as the ideal jump-off point for his next project.

Cesar selected a set of 20×8.5 Raceline El Dorado forged aluminum wheels for the front hubs, and a larger, wider set of 22x12s for the rear.

With the keys to his next ride in hand, Cesar began putting his feelers out for the right team of skilled customizers and fabricators to put his plans into motion. The first stop for the ’68 was Kid Metal Works in Alamo, Texas, where the shop’s owner and operator, Edgar Nino, was already anticipating its arrival. What he had in store for the C10’s original frame was to keep and utilize the front portion of it, but he had every intention of cutting off the rearend of the chassis right from the start. To replace it, Edgar designed a custom back half that would soon feature a C-notch and link suspension system with a frame stiffener to deliver optimum ride quality. QA1 coilovers were then affixed at each corner to further elevate the Chevy truck’s agility. Since the factory fuel cell would no longer be compatible with the new rear half of the frame, a custom tank from Boyd Welding was ordered and installed.

The much more aggressive suspension system was dialed in with and ideal ride height that would comfortably fit an upgraded set of rolling gear. Cesar selected a set of 20×8.5 Raceline El Dorado forged aluminum wheels for the front hubs, and a larger, wider set of 22x12s for the rear. The wheels have a sporty yet classic aesthetic, and they frame the Wilwood rotors and calipers lurking behind them nicely. Lionhart performance tires have also been included to give the truck the traction required to successfully whip around a road course whenever Cesar feels the urge.

The one-off bench seat was covered with blue ultra-leather and contrasting plaid inserts, and the team at Rafa’s even whipped up a new dashpad, armrests, and headliner, and laid down fresh carpeting for full in-cab refreshment.

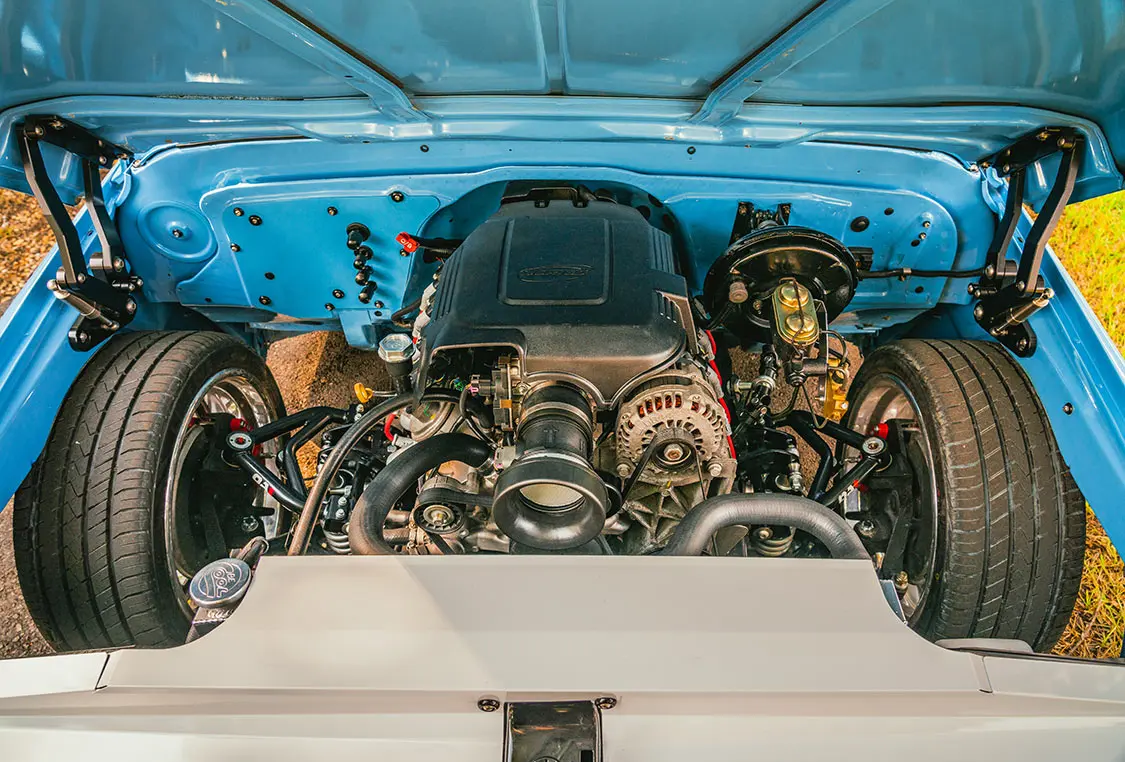

To further assist in propelling the C10 around corners and through straightaways, a 2016 Chevy 5.3L V-8 was first acquired then outfitted with a proper selection of go-fast add-ons. Of course, a correct set of motor mounts was initially required to set the modern engine into position.

To reach the engine’s full potential, a set of Hedman headers, 2-inch exhaust piping, and a Borla muffler were assembled to increase its air flow. A Holley fuel system and Texas Speed camshaft were then added to increase the truck’s overall power and reliability, and upgrades to the cooling system were made to ensure the C10 remains happy even through the sweltering Texas summer heat.

Cesar’s C10 build was taking shape quickly. To maintain its steady progress, he soon dropped it off with Revival Auto Spa in San Juan, Texas, to be primped for a full exterior overhaul. While there, Cesar communicated the plan of action he wished to see, and it was followed through exactly how he requested it to be done.

First, the bed had to be raised and customized as to better provide clearance for the altered frame back half below. Wider rear tubs were also fabricated, and all necessary body adjustments were expertly executed in record time. The next order of business was to apply the two-tone blue and white PPG hues, and once the entire truck was wet sanded and buffed to a blinding brilliance, the C10’s surface was sealed with a five-year ceramic coating from Shine Supply. The outcome left Cesar’s Chevy looking clean and classic, which was the exact appearance he was after.

The same clean, period-correct vibe was also the goal set for the interior space. The same color paint used on the exterior surfaces was used on throughout the cab, and what wasn’t sprayed blue was blessed with the magic touch of Rafa’s Custom Upholstery in McAllen, Texas. The one-off bench seat was covered with blue ultra-leather and contrasting plaid inserts, and the team at Rafa’s even whipped up a new dashpad, armrests, and headliner, and they laid down fresh carpeting for full in-cab refreshment. While the interior didn’t take too wild of a turn in the rehab process, there’s a lot to be said about keeping customizations simple and refined.

In only a matter of only eight months, Cesar’s ’68 crossed the finish line. To mark the occasion, it was taken out to C10s in the Park, Summer Show-Off, and Dino’s Git Down, and the truck received rave reviews across the board, which isn’t a surprise.

“The blood, sweat, and tears are paid off with one good compliment,” Cesar remarks about the completion of his latest high-profile project. “Things have to look ugly before it they look good, so for those who are facing any struggles related to a personal build, don’t give up!”

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link