Alfie Bilk

.

July 20, 2022

.

All Feature Vehicles

Alfie Bilk

.

July 20, 2022

.

All Feature Vehicles

Introducing a new engine block with a big power potential understandably gives rise to a sense of occasion. First, consider the time and treasure invested in its creation. Also, consider the enormity of the engineering details and the designer who tirelessly examined hundreds of complex regions of the new casting. It’s an endeavor not for the faint of heart.

But its culmination is exactly what we observed at the end of 2014 when, during the PRI exhibition in Indianapolis, World Products unveiled two innovative Ford-based blocks. Both defined as small-blocks, they are distinguished mainly by their deck heights: one measures 8.2 inches, the other 9.5 inches.

The 9.5 version displayed in finished form sported a displacement of 454 ci (7.4L), exhibited a host of advantages and echoed the biggest engine news of the show. It’s called Man O’ War.

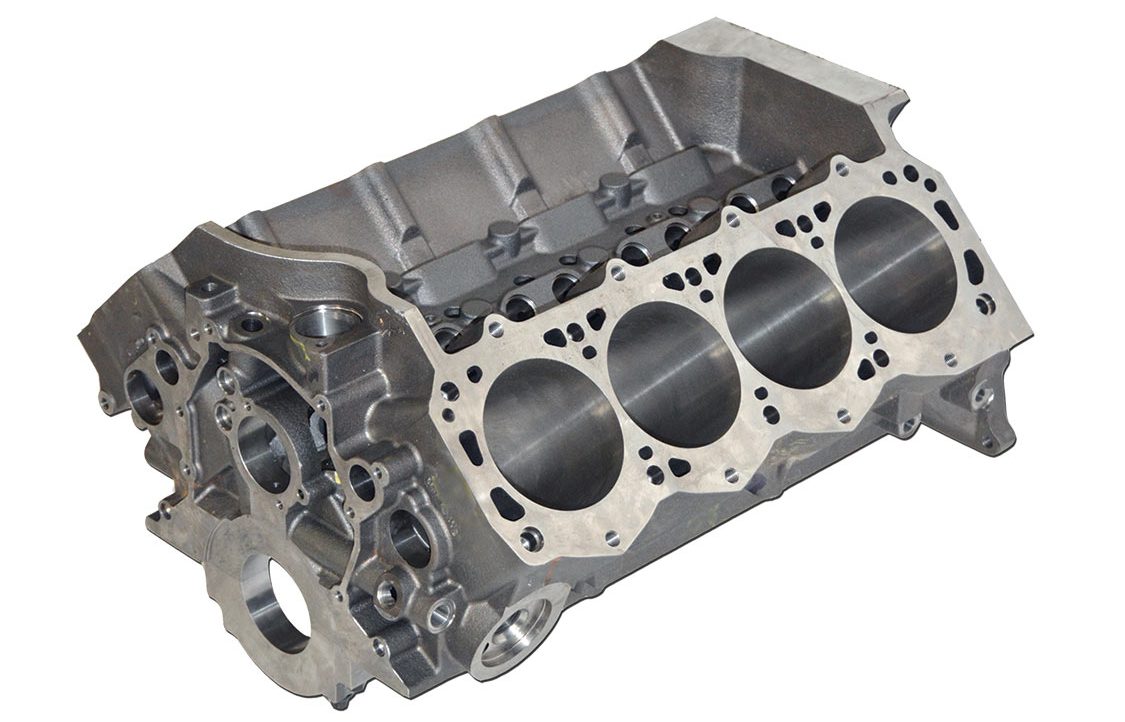

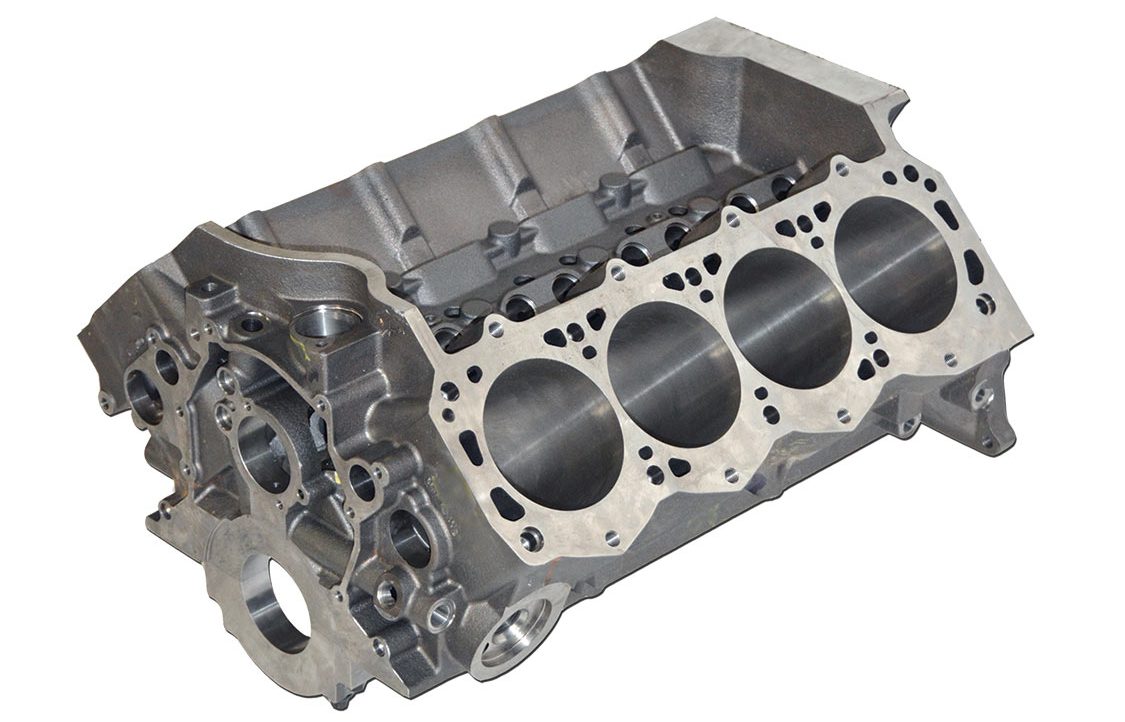

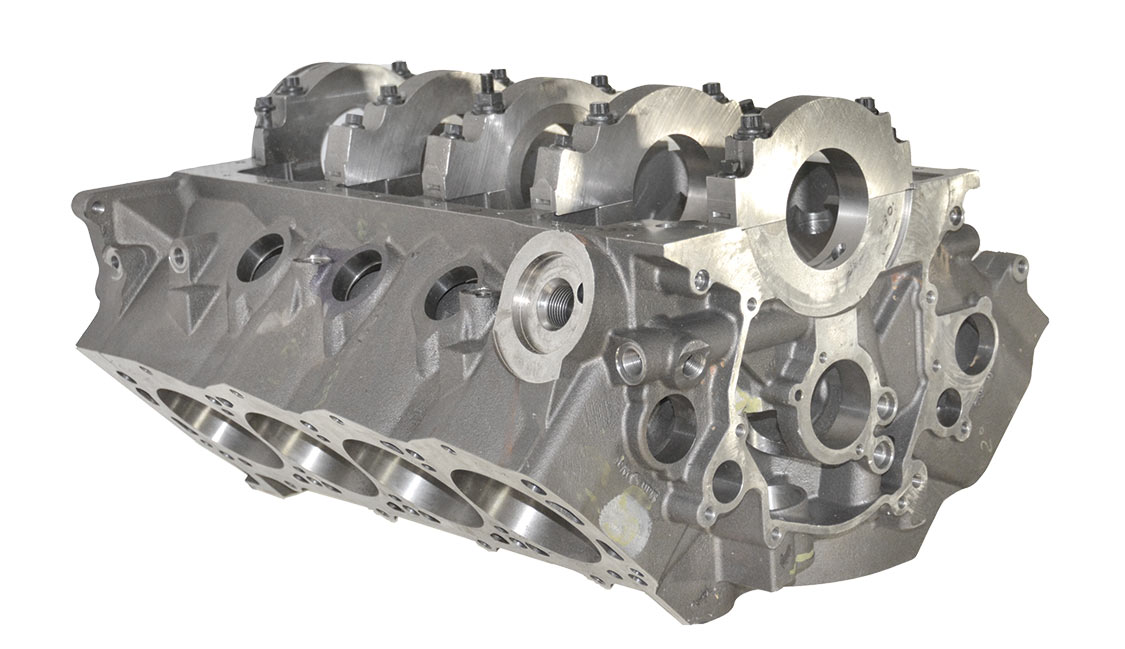

The Man O’ War block had existed previously, but when World Products was sold in late 2012 the new owners decided to entirely revise it. Now graced by new architecture and the brainchild of World’s Engineering Director, Dick Boyer, it accommodates the original 10-bolt cylinder heads as well as the latest aftermarket high-performance 18-bolt counterparts. Introducing six head bolts per cylinder combined with extra thick decks greatly reinforces gasket clamping, but its sporting credentials didn’t end there.

Devoted to the idea that the new engine should be the strongest and most rugged, Boyer, an accomplished race engine builder and tuner, cast the new power unit in 40,000-psi iron alloy. He also increased the thickness of the main bearing webs, upgrading the front one by adding 0.080 inch and the center three by 0.030 inch. To increase the main web structure further, the traditional ½-inch main cap fasteners were revised to 7⁄16 inch, leaving more material in the webs.

A replacement for both Ford’s 302 and the ubiquitous Windsor motor, World’s new block is available in two deck heights, 8.200 inches and 9.500 inches respectively. Deck heights have a direct bearing on the engine’s capacity. Shorter deck heights limit the stroke length and the engine’s cubic inch displacement.

The 9.5 version displayed in finished form sported a displacement of 454 ci (7.4L), exhibited a host of advantages and echoed the biggest engine news of the show. It’s called Man O’ War.

The 8.200-inch block is a direct replacement for 5.0L Mustangs and is compatible with OEM heads and exhaust systems. The 9.500-inch block works with all 351 Windsor-style components. Both employ Siamese cylinder bores with thick walls, which can be bored to 4.200 inches.

Much to the blocks’ credit, the bottoms of the cylinder barrels are extended down into the crankcase by 0.500 inch. This approach introduces superior piston support while operating with long-stroke crankshafts. In the case of the 8.200-inch deck blocks, clearance is provided for a 3.500-inch stroke crank while the 9.500-inch deck blocks accommodate a 4.250-inch stroke crank.

Either billet steel or nodular iron main caps are fitted. Featuring a splayed four-bolt stepped and doweled register, they incorporate ARP fasteners (bolts are used with the nodular caps, studs with the billet caps). In addition, priority mains oiling system is featured, which delivers oil to the main bearings first, ensuring reliable lubrication at high rpm. To further improve main bearing lubrication prospects, the inadequacy of restrictive oil flow was overcome by enlarging the diameter of the main oil gallery and also the passage from the oil filter to the main gallery.

Devoted to the idea that the new engine should be the strongest and most rugged, Boyer, an accomplished race engine builder and tuner, cast the new power unit in 40,000-psi iron alloy.

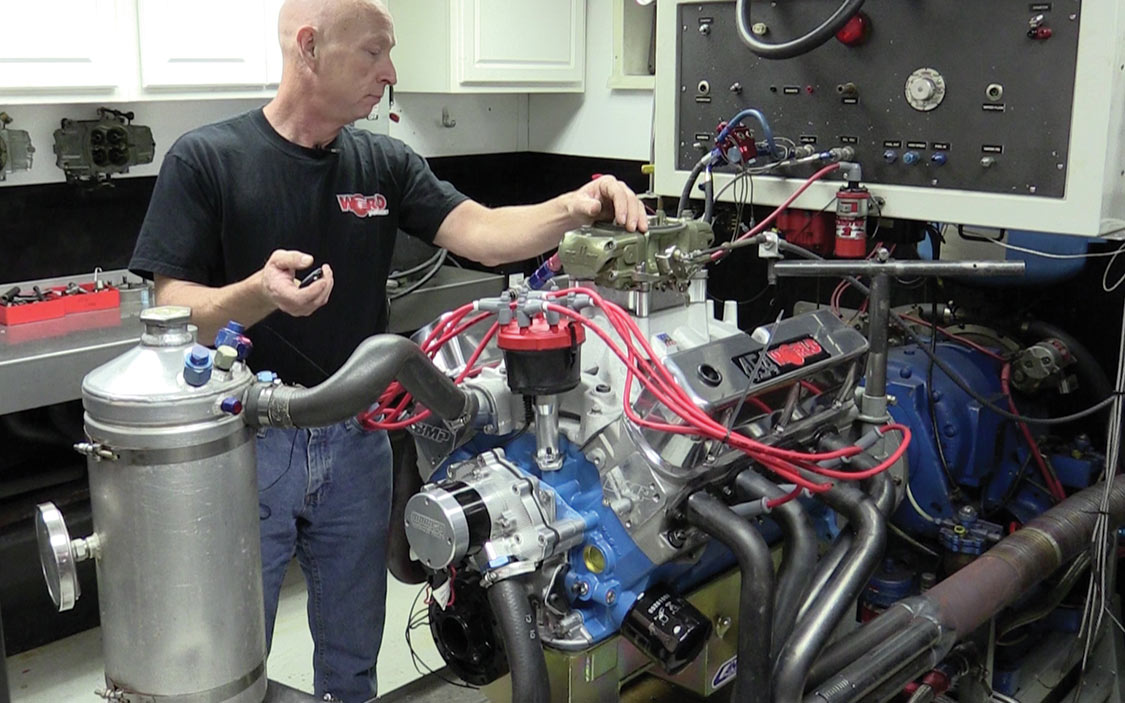

Perhaps Boyer’s real stroke of genius lies not only in combining a 4.125-inch bore with a 4.250-inch stroke, ensuring the engine would accommodate many off-the-shelf parts, but also in making it available as a complete package, if desired.

An entire kit of compatible components engineered, tested and proven simplifies construction, shortens build time and suppresses rising costs. Pushrods, for example, are supplied to the exact length and specification, and so is everything else.

Introduced in 1962 by Ford as its engine replacement for the Y-block, the rated power and torque values of the early Windsor were stated as 145 hp at 4,400 rpm and 216 lb-ft at 2,200 rpm. As it evolved during the next 40 years, it arguably became Ford’s most successful competition engine. Now revitalized for 2015 in 454-ci configuration, Boyer has brought a fresh engineering richness to the concept. By combining the new block with World’s standard kit of parts, he generated 735 hp during preliminary tests.

Finally, the blocks are semi-finished to 0.005 inch under size to accommodate 4-inch and 4.125-inch piston and ring packs. Part numbers and details are as follows:

087010 – 8.200″ deck, 3.995″ bore, Nodular 4-bolt caps

087020 – 8.200″ deck, 4.120″ bore, Nodular 4-bolt caps

087072 – 9.500″ deck, 3.995″ bore, Nodular 4-bolt caps

087082 – 9.500″ deck, 4.120″ bore, Nodular 4-bolt caps

087110 – 8.200″ deck, 3.995″ bore, Billet 4-bolt caps

087120 – 8.200″ deck, 4.120″ bore, Billet 4-bolt caps

087172 – 9.500″ deck, 3.995″ bore, Billet 4-bolt caps

087182 – 9.500″ deck, 4.120″ bore, Billet 4-bolt caps

World Products

877.630.6651

Worldproducts.net

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link