JASON MULLIGAN

.

September 27, 2022

.

Tech

JASON MULLIGAN

.

September 27, 2022

.

Tech

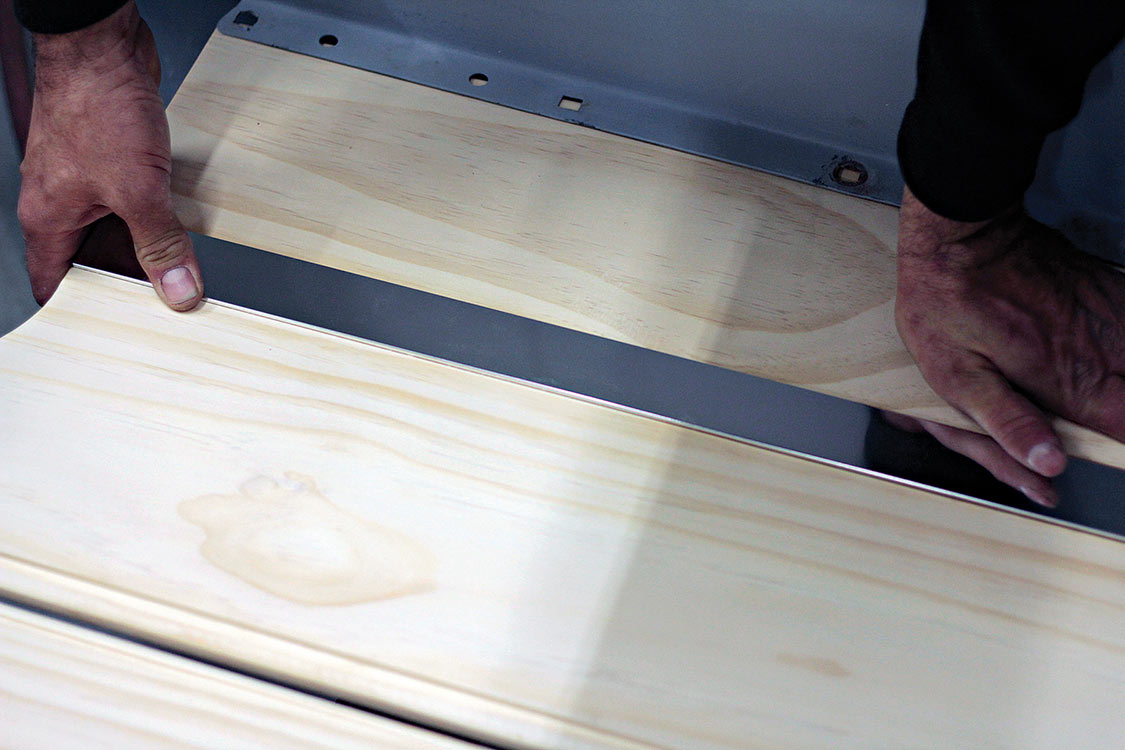

Pairing classic styling with innovation has become one of the paramount aspects keeping the automotive aftermarket industry alive and kicking. Nothing says “classic truck” like a slick wood bed floor. Most classic trucks come equipped with wood bed floors and it’s the first thing to rot and decay as the trucks age. Replacing the wood planks with factory-style restoration parts is fine and dandy,but being able to select a high quality wood from a different species of tree like common oak or exotic bamboo can set your truck apart. Bed Wood & Parts has developed application-specific kits that require no cutting to fit the factory bed.

Dozens of domestic and exotic woods are available to fit your build style. Several options of bed mounting strips and fasteners are available as well depending on your needs. Gas filler doors and hinged planks are also available. In the late-’60s, trucks began to feature metal bed floors from the factory as opposed to wood. Bed Wood & Parts offers retro liner kits for those who want a classic look on newer trucks; they’re also application specific. Custom kits for modified beds are available as well as bed racks for an old-school utility look.

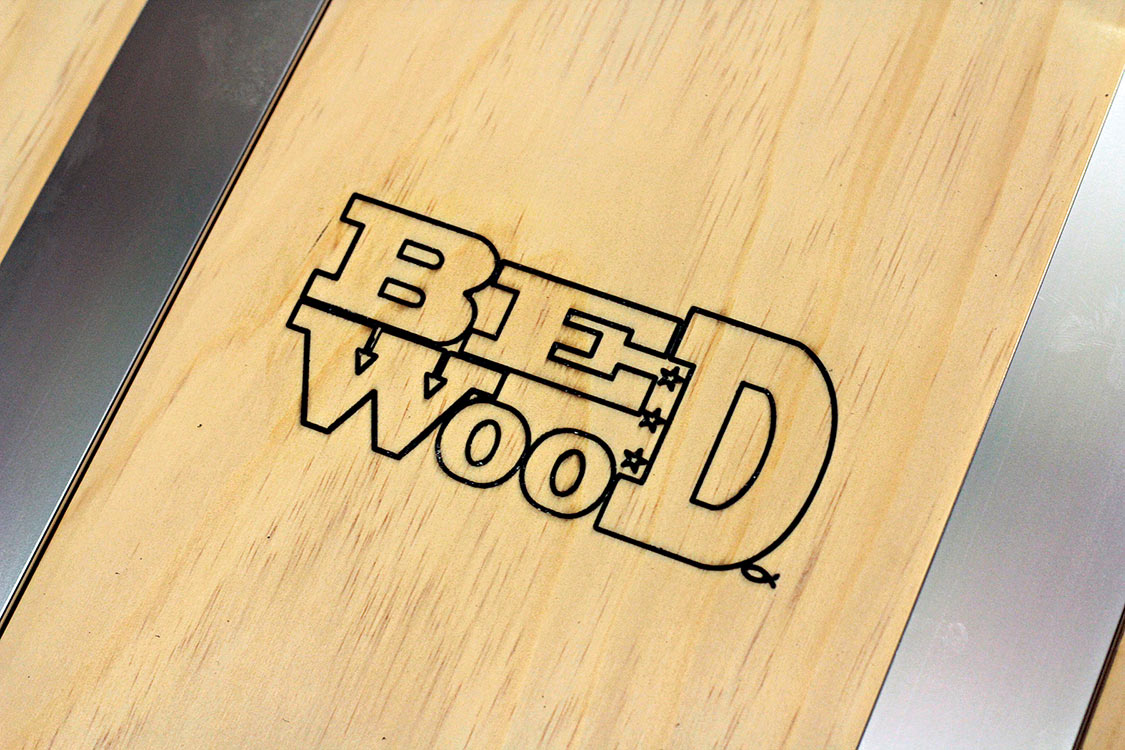

One of the new and innovative features offered by Bed Wood & Parts is wood tattoos. The tattoos can be any design or logo supplied by customers or choose from custom designs offered by Bed Wood & Parts. The design is CNC milled into the wood, and then a variety of materials and colors can be inlayed into the design and sanded smooth to create the design or logo. The pinstripe design running down the two center northern white pine planks for this ’65 C-10 truck was created with inlayed crushed turquoise and onyx for a striking look. The colors, materials and design combinations are nearly endless.

Bed Wood & Parts

Bedwoodandparts.com

PPC Customs

121 Sunnyside, Suite 201

Clovis, CA 93611

559.281.8484

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link