STEVE TEMPLE

.

October 10, 2022

.

All Feature Vehicles

STEVE TEMPLE

.

October 10, 2022

.

All Feature Vehicles

As much as we like the look of a big-block V-8, there’s one drawback: poundage. This mass of metal can weigh as much as 140 pounds more than a typical small-block. And seasoned driving enthusiasts worth their salt know that this lump seriously impacts the power-to-weight ratio, not to mention handling. Changing this equation by reducing excess heft means increased quickness for the same amount of power. Why work harder when you can work smarter?

Sure, you could go with aluminum heads and block, but that creates another quandary, higher cost. It makes good sense to stick with a more affordable and lighter cast-iron small-block and squeeze out as many cubes as possible.

That’s exactly what Smeding Performance has done with its 427 Cobra Special, which costs less than $11K (far less than many big-blocks). By staying light on its feet, the company has built up a cost-effective, lightning-quick counterpuncher. This high-power stroked 351 Windsor belts out a wicked 560 horses and 560 lb-ft of torque.

More important than the peak numbers, though, is the width of the powerband. “The torque range is what’s really awesome,” notes Ben Smeding. “Torque at lower rpms is what gets the vehicle moving, and it’s what you need when you have taller gears or an overdrive transmission.”

Smeding specializes in building stroker motors because this type of engine makes loads of torque at low rpms, while still being a smooth and tractable package. “From the block to the crank, to the rods, to the induction system, the 427 Cobra Special is built to be an all-conquering powerhouse,” Smeding proclaims. “Yet it’s still a street engine that runs on 91-octane pump gas.”

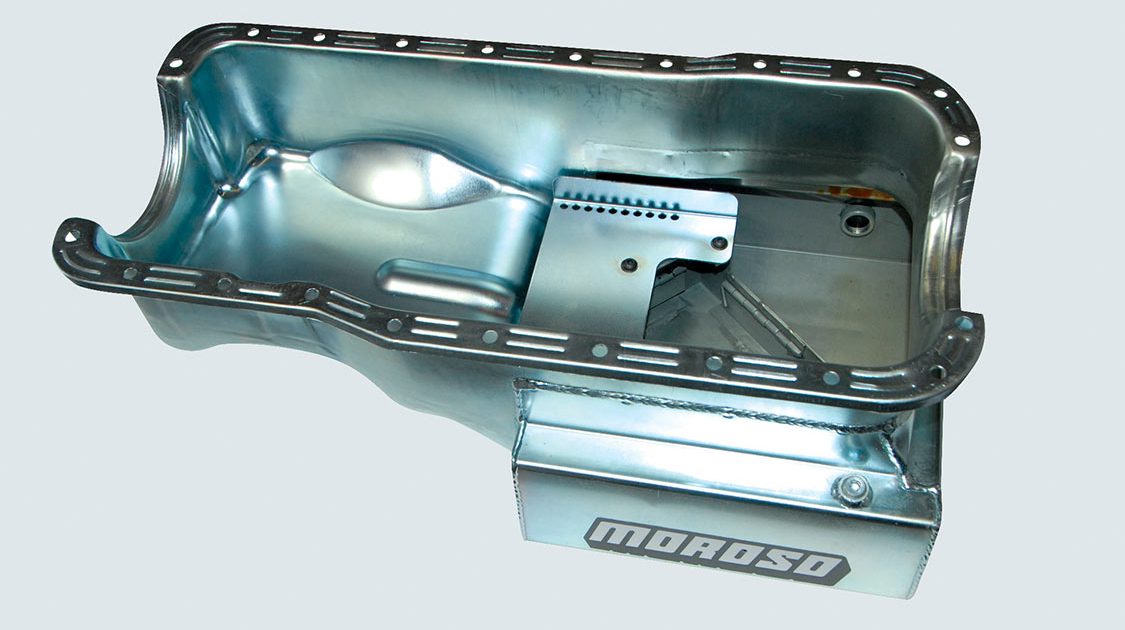

Besides increasing the stroke of the crankshaft to increase displacement, Smeding employed several other precision techniques to reduce weight, increa se strength and improve combustion efficiency (noted in the photo captions). In addition, by tightening the internal tolerances, he was able reduce the oil flow by as much as 50%, which in turn allows operators to run a standard-volume pump. With less oil sloshing around, Smeding says he recaptures as many as 30 horses, and that’s all simply due to minimizing friction losses. After all, it’s just good sense to recapture power that’s otherwise being sacrificed to resistance in the rotating assembly, rather than trying to make more horses.

The bottom line is that the Smeding offers big-block numbers in small-block packages, either Ford or Chevy, that are both lighter and less expensive, and spin more freely. All of which means these stroked small-blocks pack the punch of a heavyweight.

Smeding 427 Cobra Special Engine Produces 560 hp, 560 lb-ft torque

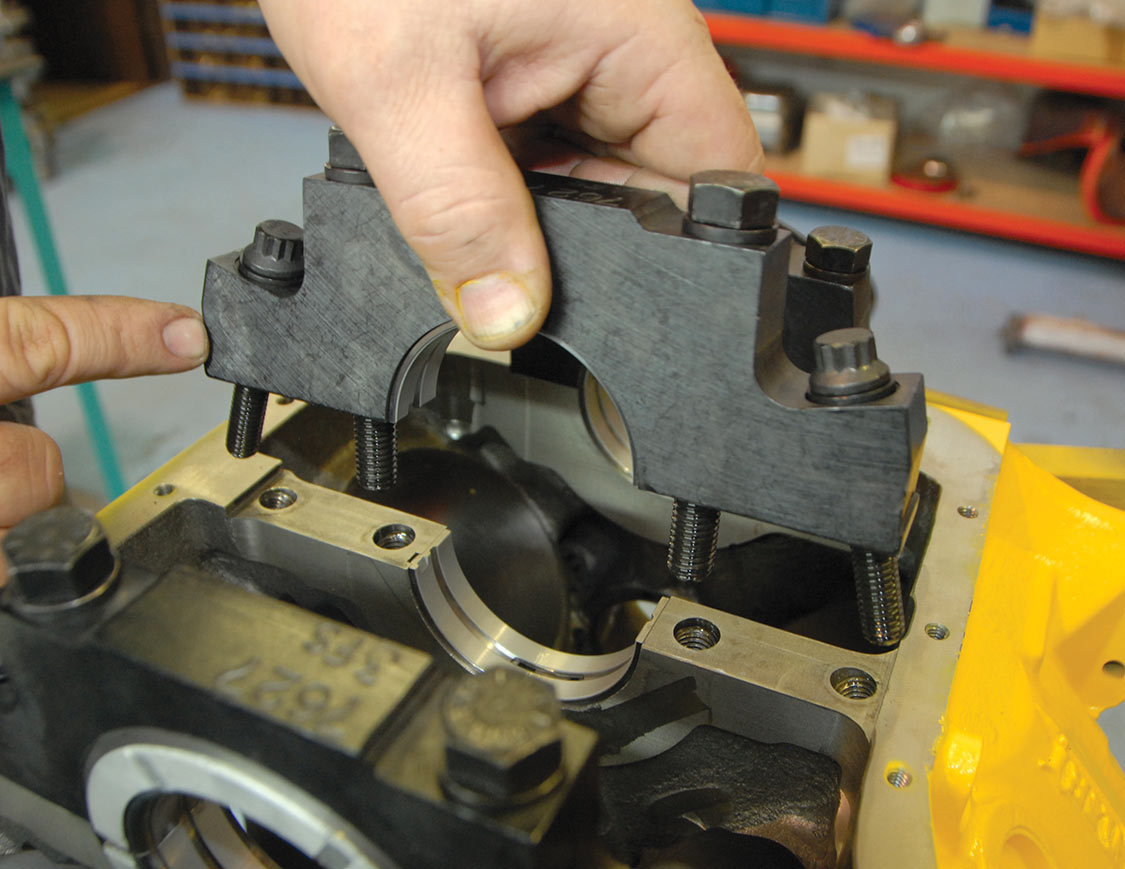

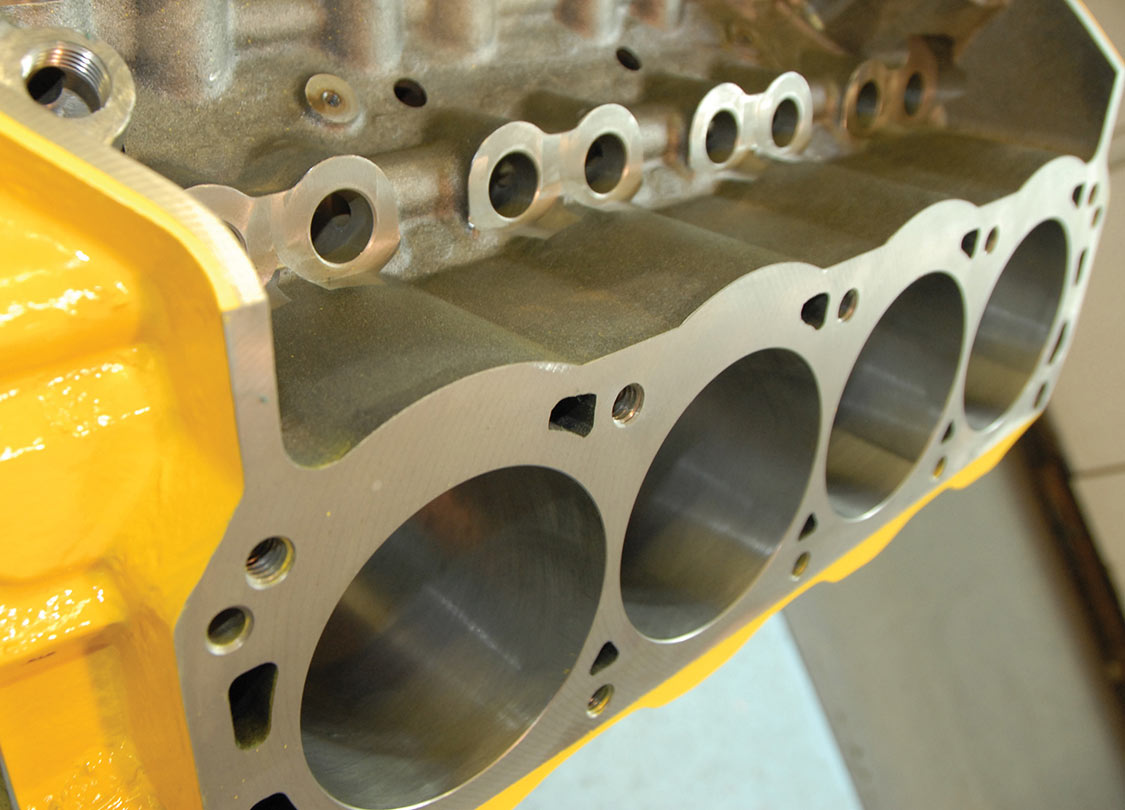

Block: Dart with splayed cab four-bolt mains, CNC machined, 4.125 bore, scalloped water jackets, one-piece rear main seal

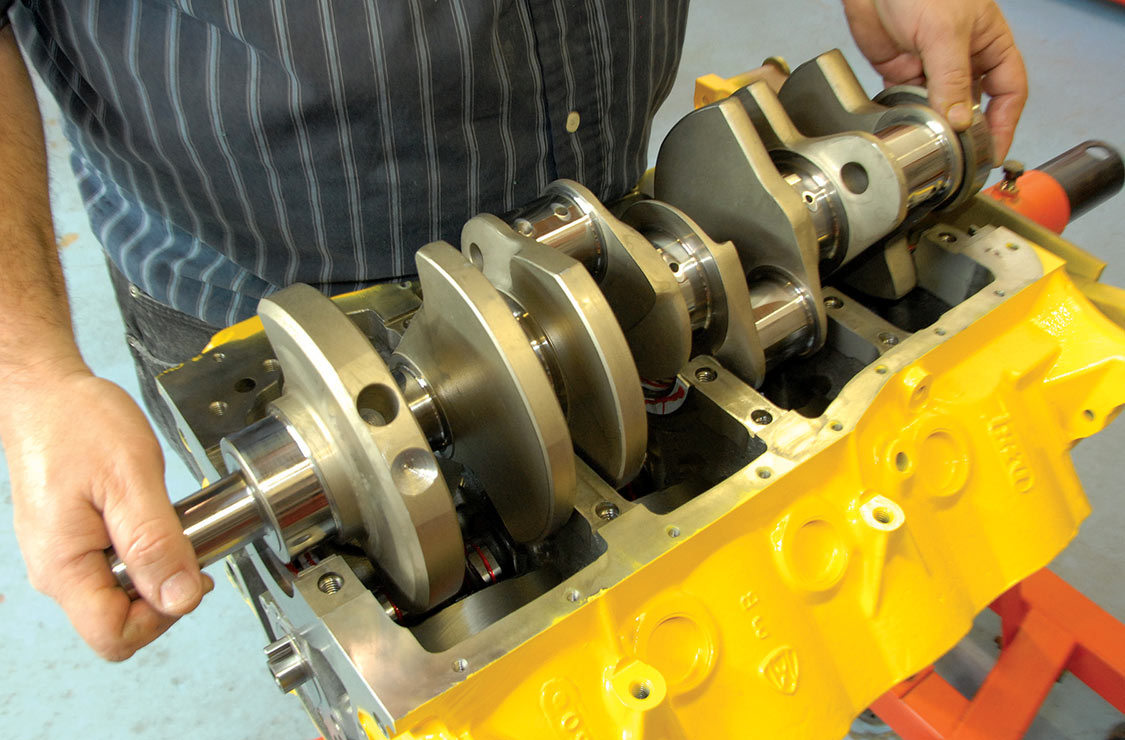

Crankshaft: 4340 steel, non-twist forging, micro polished, and chamfered, internal balance, 4.000-inch stroke

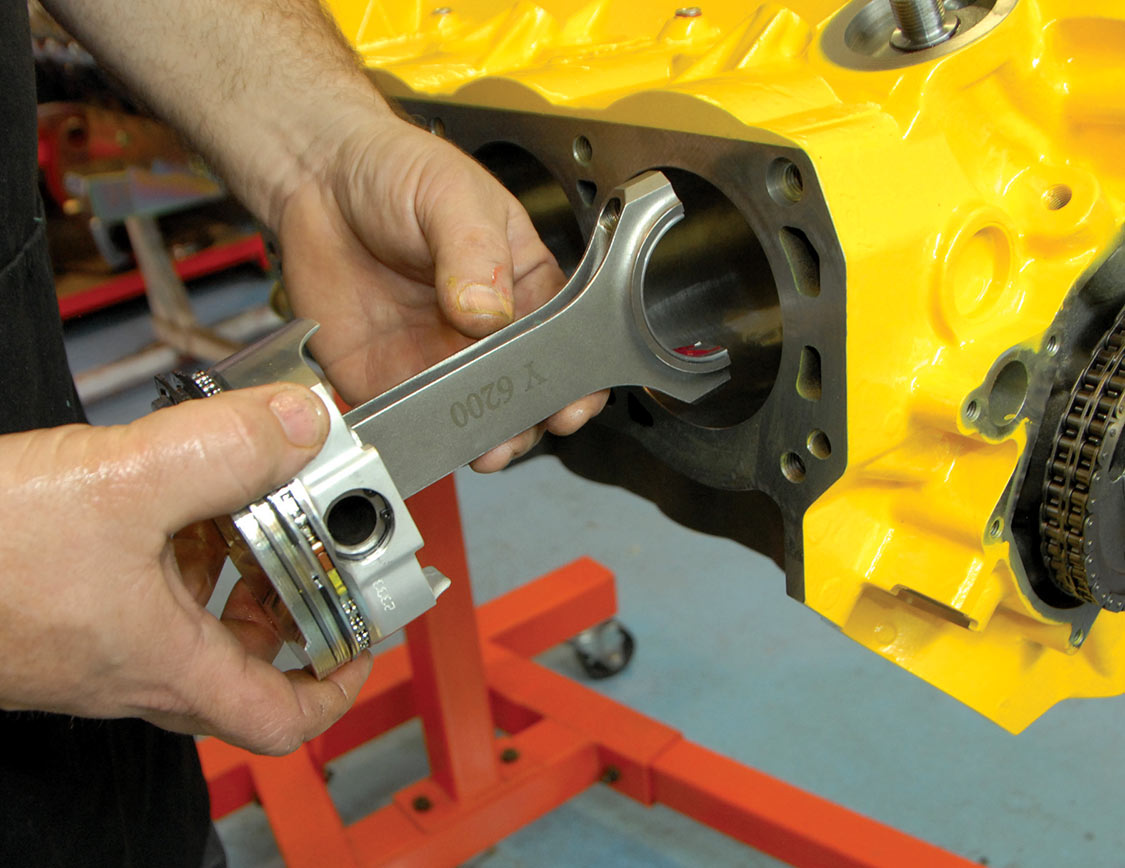

Rods: 4340 steel H-beam with 7⁄16-inch ARP cap bolts, 6.200 inches length

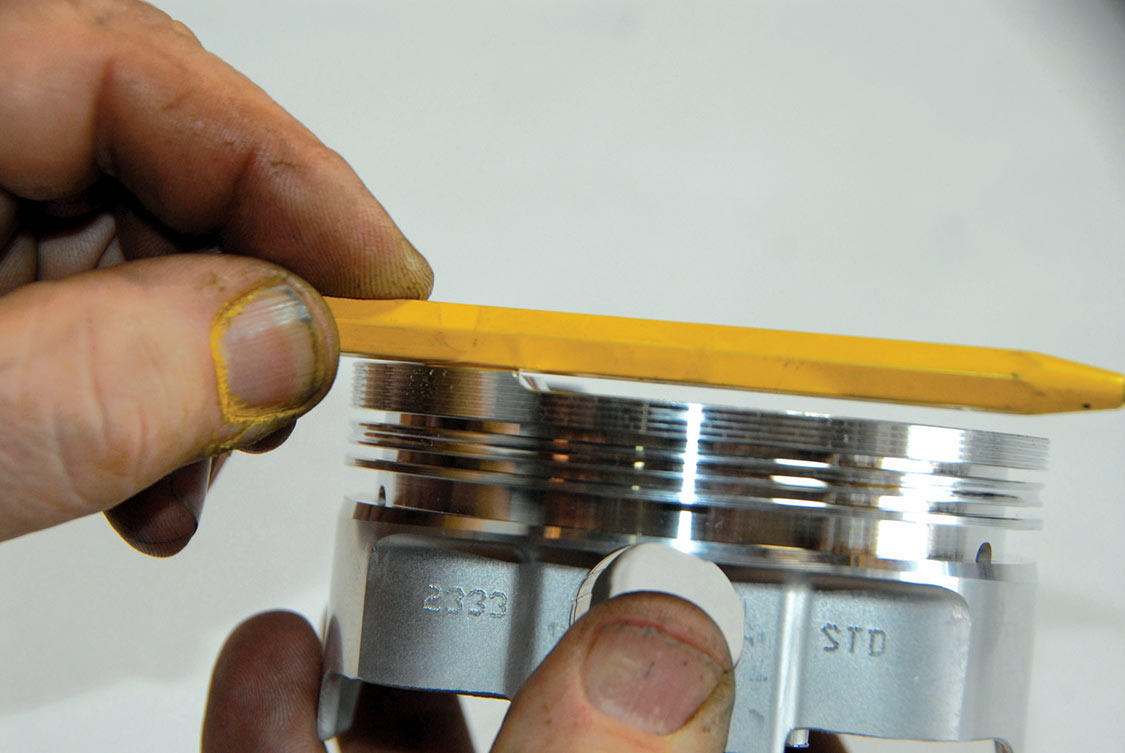

Pistons: Lightweight forged, reverse dome, 10.2 compression with wrist pin below oil ring

Rings: Low-friction single moly 1⁄16 x 1⁄16 x 3⁄16 inches

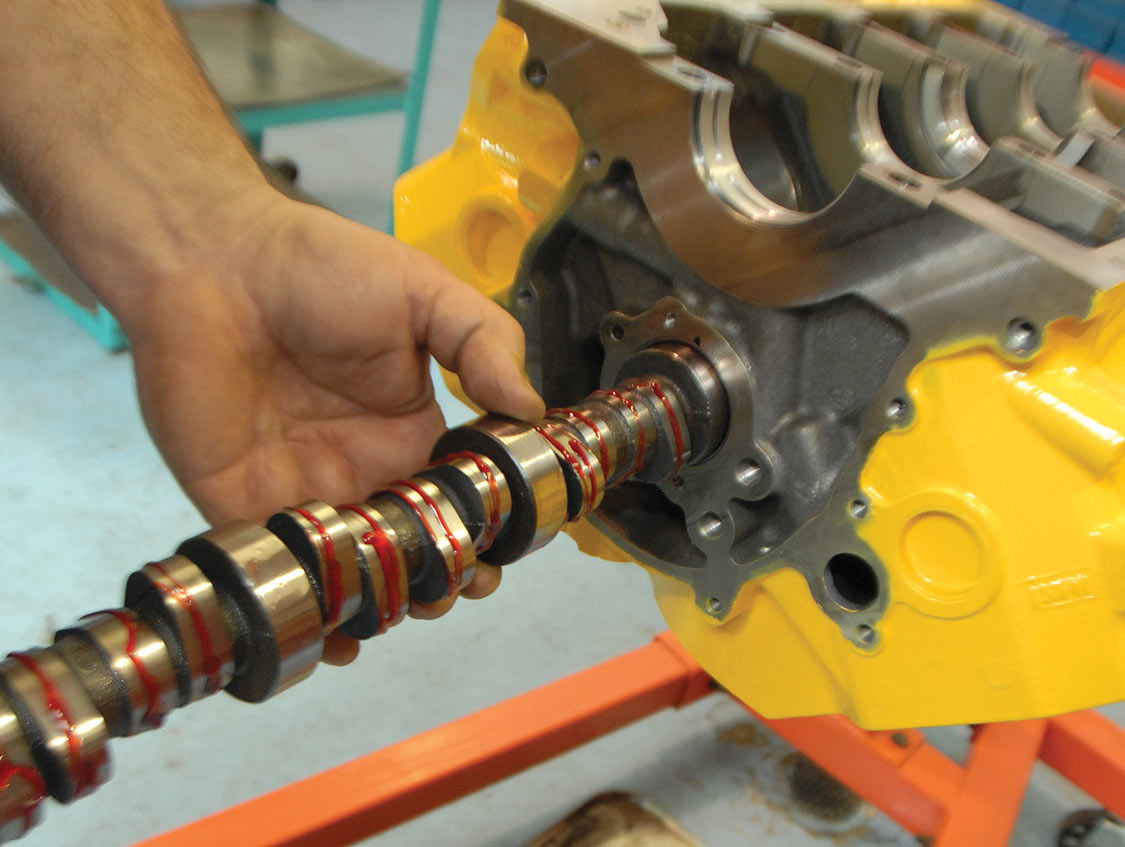

Camshaft: Custom-ground hydraulic roller .544/.573-inch lift, 238/248-degree duration at .050 inch

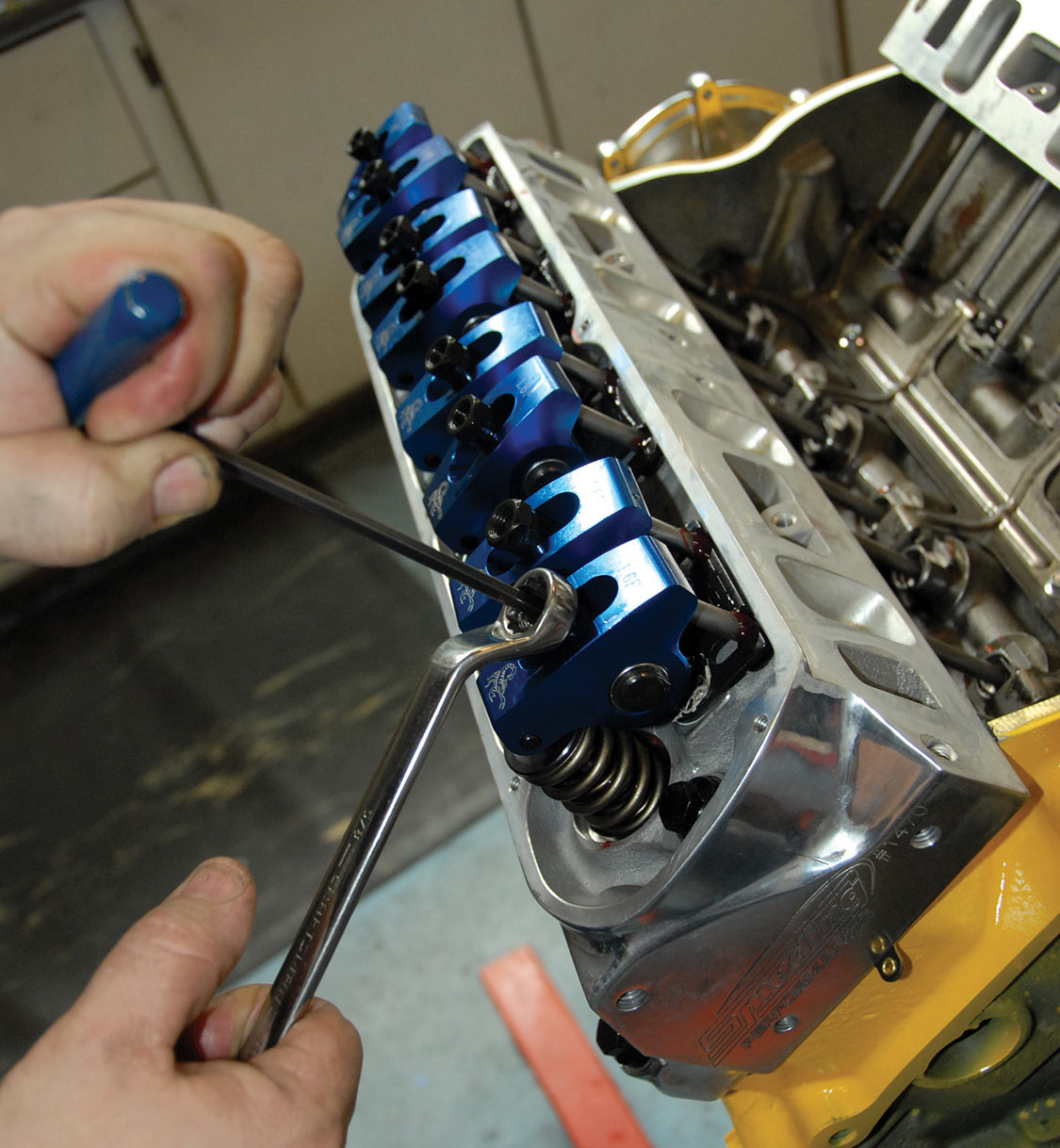

Rocker Arms: 1.6 ratio, full roller to reduce friction

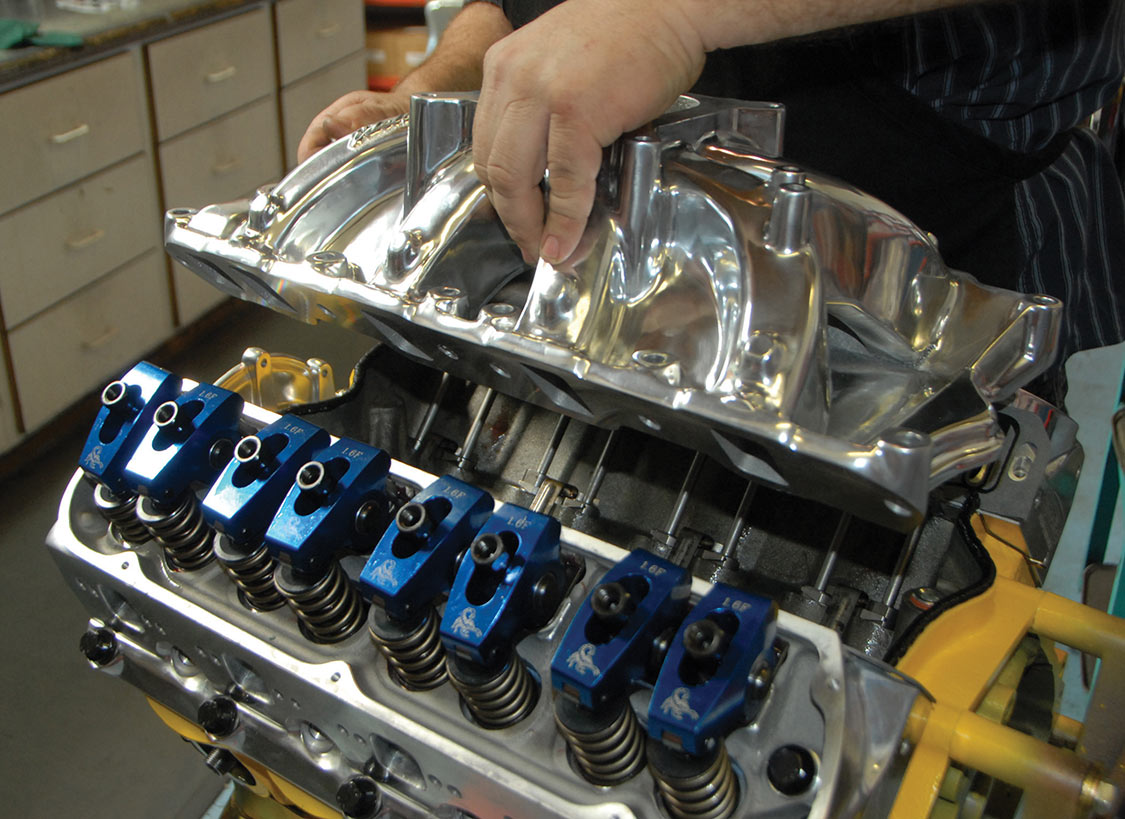

Intake: Edelbrock Victor Jr.

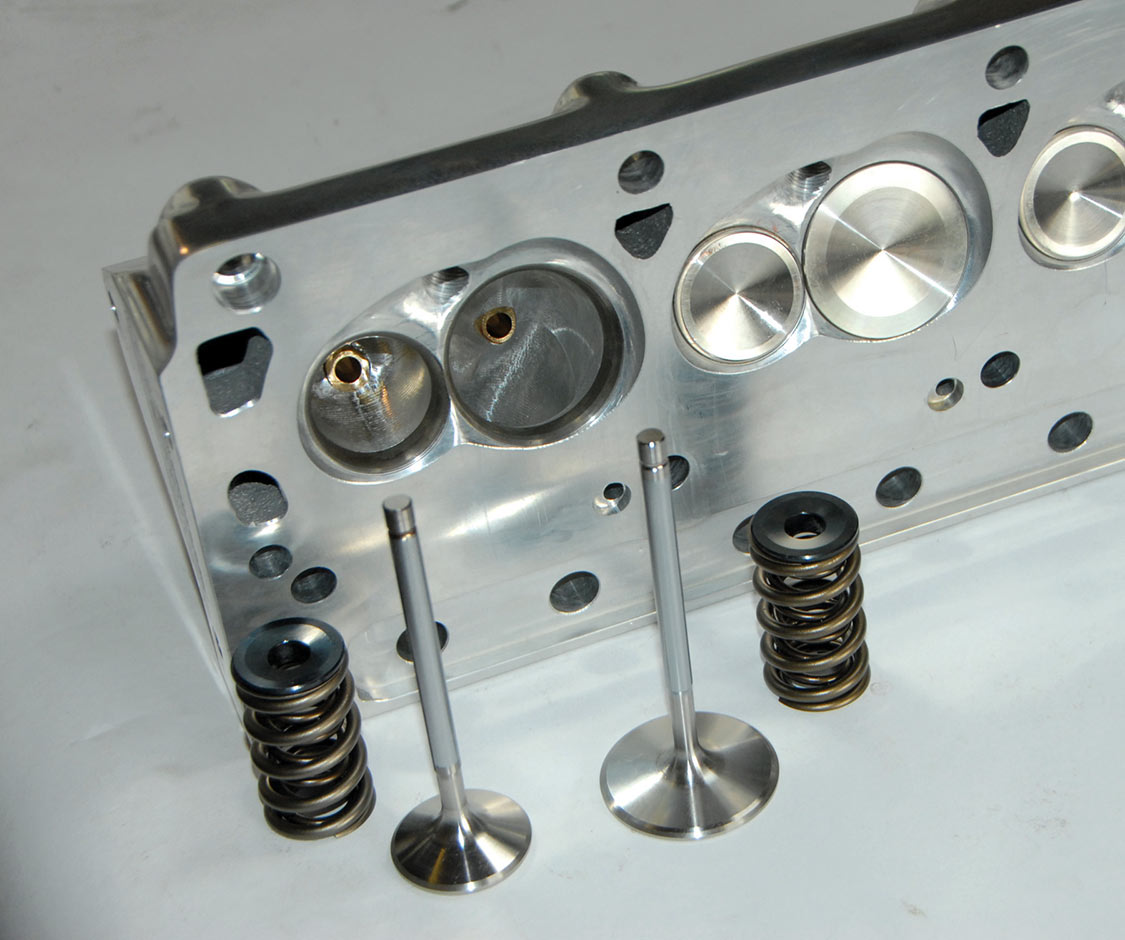

Cylinder Heads: Smeding/AFR 205cc intake port, fully CNC ported, 2.08/1.60-inch valves

Carburetor: Quick Fuel 750, dual feed, double pumper, calibrated and tuned on Smeding’s dyno

Distributor: Hall Effect electronic, polished billet aluminum housing

Price: $10,995 (includes dyno testing and tuning)

Options: 8-stack fuel injection, Cobra valve covers, MSD distributor, aluminum lightweight block, front-drive setup, water pump

Smeding Performance

28875 Interstate 10W

Boerne, TX 78006

877.639.7637

210.338.8585

Smedingperformance.com

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link