Sam Logan

.

January 10, 2023

.

All Feature Vehicles

Sam Logan

.

January 10, 2023

.

All Feature Vehicles

You might say that you could just go out and buy a used LS motor. It’s a modern power unit, bestowed with high flowing heads, is readily available, and affordable. All the benefits you could desire. Except there’s a catch—the fact is you have to do a lot of work to get it installed properly, and also be burdened by appreciable expenditures.

If you are empowering any pre-1990s muscle car with an LS-series engine it is usually not a simple swap. And it’s not just exploring engine and transmission mounting solutions and clutch actuation. There are EFI and ignition considerations, a fuel system design, plus numerous cooling and engine accessories questions to resolve. The fact is that mounting a pair of LS-series cylinder heads on a small-block Chevrolet is a much more practical solution.

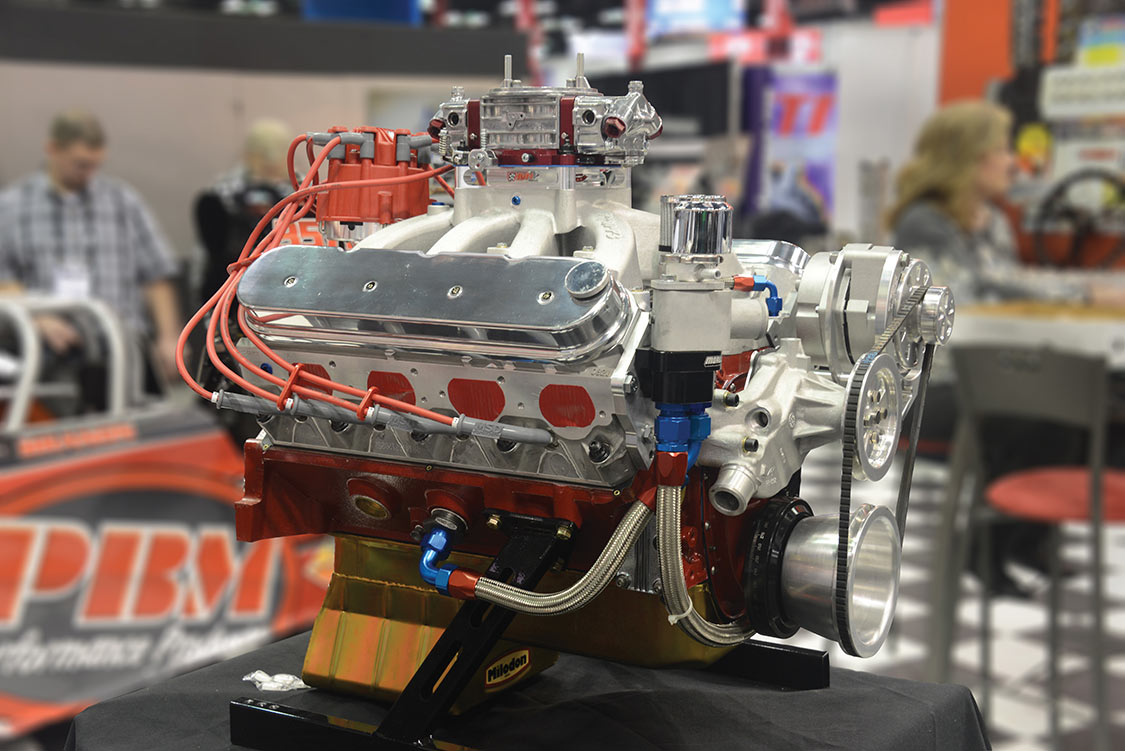

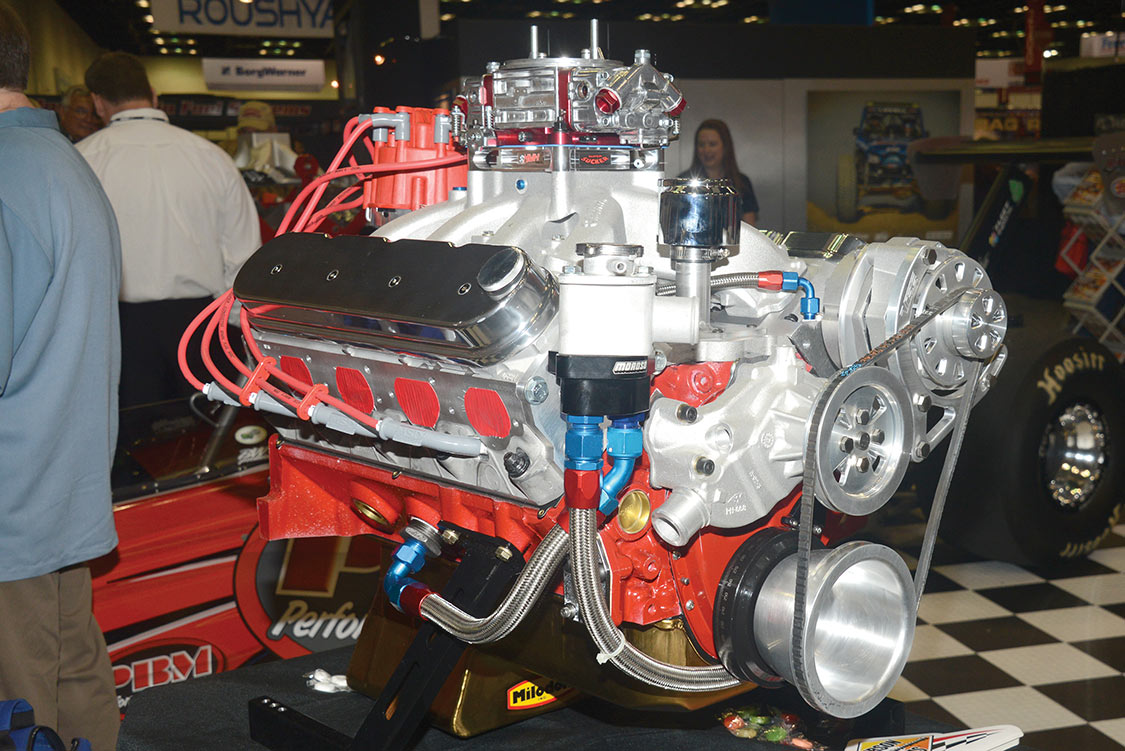

Weighing 210 pounds and employing standard LS deck height, the Motown LS is a cast iron small-block that accepts LS-series cylinder heads. Developed under the insightful command of Dick Boyer, the architect of the previous year’s 454 Man O’ War Ford block, it is unique and thus one of the most interesting new engine of 2016.

Available in two versions, a street-strip and a race variant, the former generated just under 640 hp at 6,400 rpm in 427 cu. in. configuration. The drag race version uses a higher compression ratio and a solid roller camshaft. In the interests of valve train stability, Boyer’s agile mind incorporated several other interesting attributes, including useful camshaft reforms.

Crankshafts of 3.750 in stroke or more cause interference troubles in small-block Chevrolets. Boyer’s solution was to raise the camshaft by 0.134 in. This formula accommodated the larger 55 mm cam core, which is one of the chief power benefits of the LS engine design. These new custom cam cores, incidentally, are available through Erson Camshafts for the same price as the standard Chevrolet LS cam.

What’s the advantage of the desirable and readily available 4in stroke 350 crank? Well, more stroke length means more displacement—more cubic inches. Are there any disadvantages? Not really. The raised camshaft requires a different gear set. But the cam’s relocation has no effect on the timing cover, oil pan, oil pump or distributor ignition system—all of which remain standard. It’s also worth noting that Jesel has introduced a specific belt drive assembly for the Motown LS.

Naturally, the Motown LS features a priority-mains oiling system to ensure reliable lubrication of the main bearings. Another key innovation is its reverse-flow cooling. In common with GM LS engine blocks and cylinder heads, the purpose of reverse flow is to distance the threat of detonation by introducing not only colder coolant into the heads, but also higher coolant pressures. Higher coolant pressures raise the boiling point, which is particularly advantageous around spark plugs and combustion chambers.

Like World Products’ Man O’ War block, the Motown LS accommodates many off-the-shelf components. A standard LS 9.240in deck height, for example, means standard LS intake manifolds can be used. In addition this block is available separately, or with associated components or as a completely assembled ready-to-run package.

In conclusion, the Motown LS doesn’t have engine and transmission mounting concerns holding it back. It doesn’t have clutch actuation, EFI or ignition bothers restraining it. Also it doesn’t have fuel or cooling system redesign questions to resolve. Mounting a pair of LS-series cylinder heads on a small-block has much to recommend it.

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link