BRANDON BURRELL

.

August 20, 2024

.

Feature Stories

BRANDON BURRELL

.

August 20, 2024

.

Feature Stories

Are you looking to add some must-have options to your truck that’ll see lots of use? Search no further than an onboard air system.

I have added onboard air to every one of my SEMA builds since 2014 and used it in multiple ways over the last decade, whether it’s to keep the truck and trailer tires properly inflated, blow water out of wheels and crevices after a car show rain shower, or help a buddy’s unfinished truck air up so it can be pushed back on the trailer at the end of the weekend.

Not only do train horns provide added safety, but they also add a ton of fun scaring your friends and innocent bystanders.

Having access to compressed air has almost endless possibilities. If you’re into off-roading and like to semi-deflate your tires for better grip on rock and then air them back up to drive the truck home, a system like this can be a lifesaver. Even the bagged vehicles I’ve built had a quick-connect added to be able to utilize the compressed air when needed.

My Sierra isn’t bagged, but I knew it would be a driver and be at a ton of shows in the coming months, so I planned to have an onboard air system mounted on it. As usual, I contacted Viair Corporation to see what options it had for my needs. I have had Viair components on every build I have done and knew the company had the parts and equipment I needed to make sure I always had compressed air.

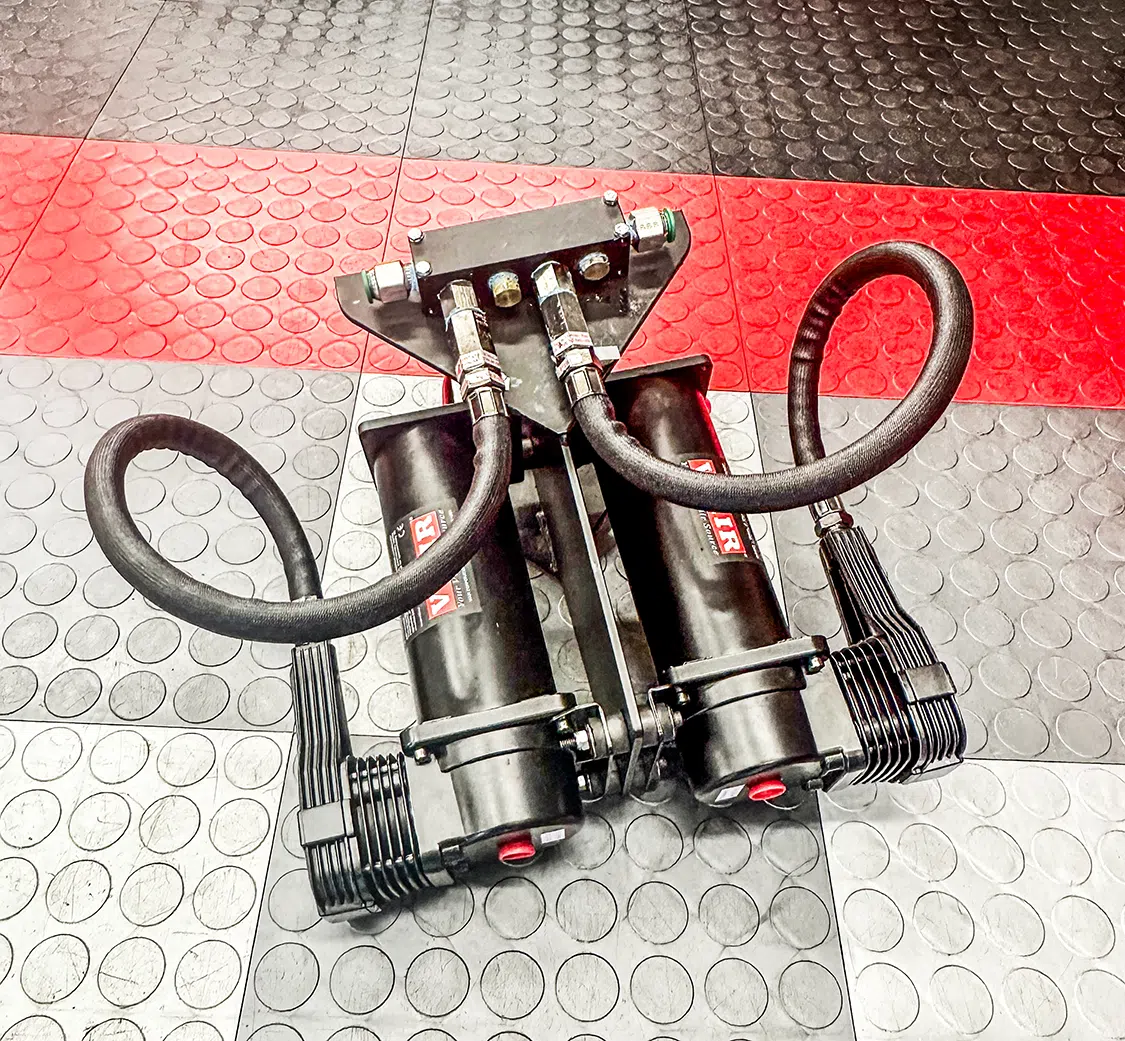

Viair has been releasing new parts and mounting hardware on a regular basis, but unfortunately, it doesn’t have a direct bolt-on kit yet for the ’22+ GM trucks. The team there put together a kit that would work with my truck with a 2.5-gallon air tank, two 485 Stealth compressors, all the fittings, pressure switch, and needed air line. That would give me 200 psi of air at any given time.

Knowing I didn’t want to mount everything in the bed, I contacted J.R. at Parker Speed to design and build brackets for the tank and both compressors. This ensured they would be tucked out of the way and securely mounted to the frame. All the brackets were powdercoated before assembly to make sure they wouldn’t rust.

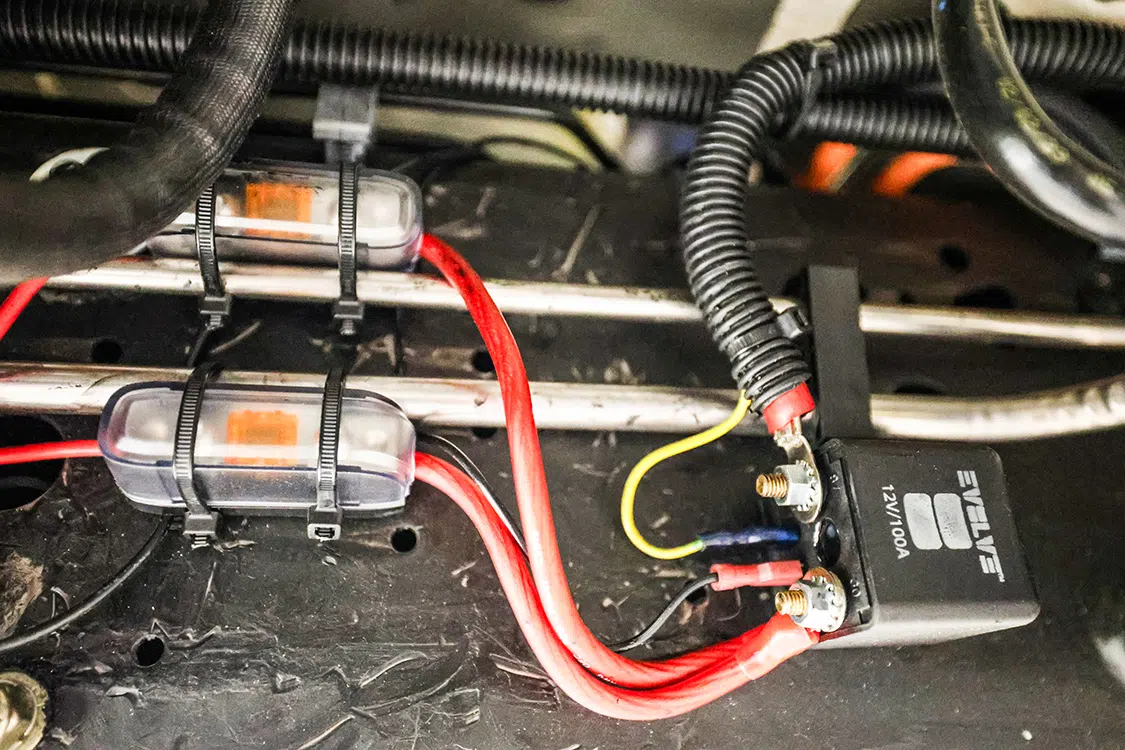

Once I had the air-system mounts figured out, I contacted AVS and ordered one of its Evolve Dual Compressor Wiring Kits. This made the wiring of both compressors super easy with all needed fuses, larger-gauge wiring, and the relay to provide the needed power to both compressors.

One of the advantages of adding an onboard air system is that you can also add a set of train horns. Not only do train horns provide added safety, but they also add a ton of fun scaring your friends and innocent bystanders. Honestly, train horns are always one of my favorite parts to any vehicle. For that, I got with Horn Blasters and picked up one of its Shocker XL train horn kits. This kit gives you four trumpets, the valve, fittings, and air line needed.

Just like the air system, the train horn kit doesn’t include a universal mounting system for my application (and most likely for your needs, too). So, I picked up some simple brackets from a hardware store and easily mounted the horns out of the way. Working the horns into the onboard air system install made perfect sense considering they needed to be plugged into air tank.

Not counting designing the brackets and powdercoating time, this project only took a couple hours. So, if your truck is stock height, you can do something like this in your garage or driveway easily with a few hand tools. If it’s lowered like mine, you’ll need to jack up the truck unless you are super skinny.

Follow along with some of the details about how the onboard air system and train horns were installed.

Viair Corporation

949-585-0011

www.viaircorp.com

@viaircorp

Parker Speed

828-734-8031

www.parkerspeedshop.com

@parkerspeed

AVS

559-486-5444

www.avsontheweb.com

@avsonthewebdotcom

Horn Blasters

877-209-8179

www.hornblasters.com

@hornblasters

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link