Dan Burrill

.

March 06, 2023

.

All Feature Vehicles

Dan Burrill

.

March 06, 2023

.

All Feature Vehicles

There are a lot of older Ford Mustangs still around and they are still very popular. Brad Selland really liked his 1967, but he wanted his to be very different. He wanted it to be over the top.

“I felt this car had a lot of potential and I knew that if the changes were somewhat subtle, it could be a real hot-performing car and a ‘stand-out’ show car,” Selland said. “I wanted the best in the business to help with the design, and I knew it would take a top shop to create this concept car.”

So he commissioned Brian Geiszler, a graduate of the Art Center College of Design, to create a rendering of what the finished car would look like. Geiszler drew up a complete body exterior and interior redesign for Selland’s approval.

Of course, it’s a long and expensive road from a rendering on paper to a finished car.

“The classic 1967 Ford Mustang is really a neat base car to redesign,” said Geiszler. The lines are already graceful and with some thought and a good amount of time spent with Selland, I was able to create and render exactly what he was looking for in his performance/show car.

The exterior design was accepted with a few minor modifications. The work was started by a company well known for creating over-the-top show-and-go classic cars: Restorations and Reproductions in Gresham, Oregon. Thousands of hours later, every panel on the car had been substantially altered for a very unique look. Much of it was subtle. The more you study the overall finished design, the more the changes become apparent.

Once the exterior design was agreed upon, it was time to come up with an interior that would complement the overall design. After making several different interior drawings, one was selected and the result was an interior that blended with the overall design.

Of course, it’s a long and expensive road from a rendering on paper to a finished car. Needless to say, there were some changes made along the way. Some were design changes and some were modifications so everything fit perfectly. The finished project would be flawless.

Once the car was completely stripped down to a bare chassis, with all the suspension removed, it was minutely inspected for any damage, cracks or rust. All these issues were fixed and the project moved to the next phase.

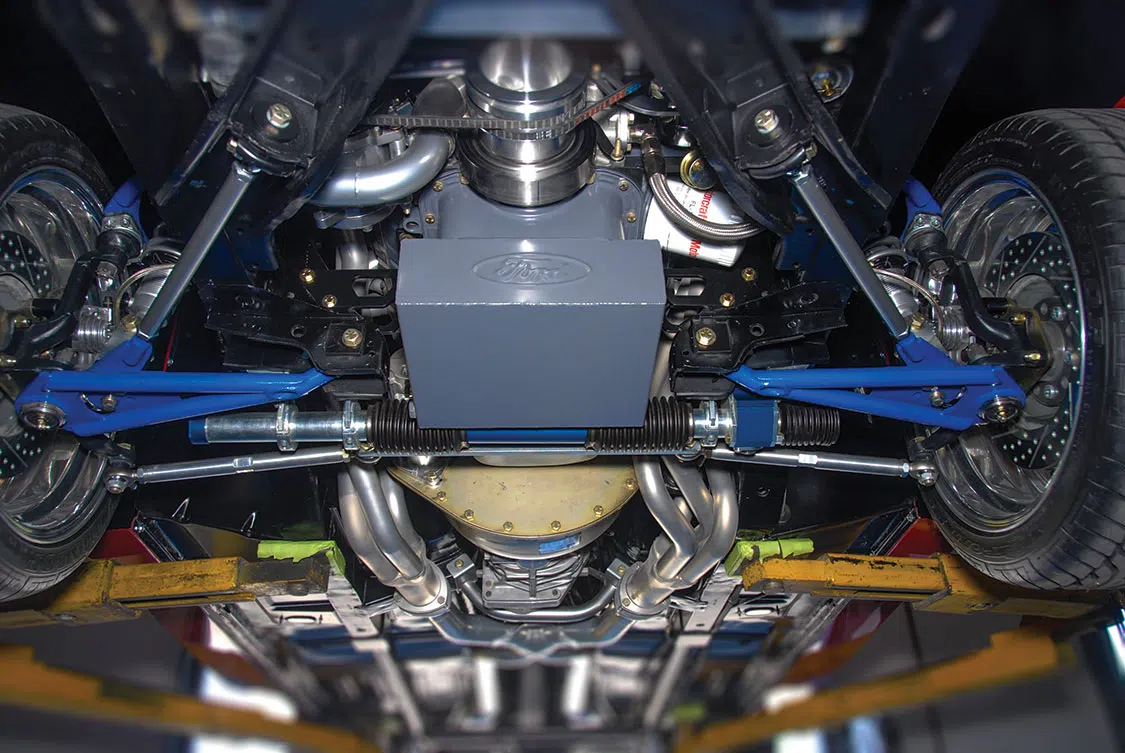

First up was the suspension. The car’s old original front suspension was removed and a new power rack-and-pinion unit from Total Control took its place with custom A-arms and coilover shocks. The TCP front coil-spring suspension is a fully adjustable suspension system that utilizes the key factory mounting locations to greatly simplify installation.

For front and rear, the VariShock shock absorbers with coilovers control installed determine the ride height and amount of travel. The mounting configuration for both front and rear was built to exact specifications. The VariShock’s quick set design is adjustable and features 16 different settings so it’s easy to tune or change from road or track.

Aldridge Motorsports built the entire engine and drivetrain. “We wanted a 351-cu.-in. Windsor because we could safely build it up to 460 hp and it would perform well through all the gears, and it would last,” said Denny Aldridge. “With this much power, I felt with my years of experience that the 9-in. Ford differential with the Detroit Locker was the obvious choice for this application.”

Ron Morfitt Mixed colors trying to come up with the perfect “lipstick” red. “It took days going through variations to come up with the right color. We would mix a shade and then take it out in the natural light to see what it really looked like. We must have done that a hundred times.”

Once the suspension and drivetrain were in, it was time to go topside and start working the magic. The bodywork is extensive. Every panel was modified in some way. The door handles and all badges were removed to add to the shaved, sleek look with unbroken lines. The fit and finish is flawless. The aluminum tube grille was custom-made and fitted into the new fiberglass nose by Mike Markovich.

While the bodywork alterations were in progress, Ron Morfitt at Jerry’s Custom Paint was mixing colors trying to come up with the perfect “lipstick” red.

“It was really a lot harder than one might think,” Morfitt explained. “It took days going through quite up with the right color. We would mix a shade and then take it out in the natural light to see what it really looked like. We must have done that a hundred times.”

“As things got underway, I could start to visualize the finished car and could see there were some changes I wanted to see happen,” Selland said. “One was having larger wheels and tires.

Once Geiszler designed the requested one-off wheels, he traveled to Boze Alloys to discuss actual production of the special wheels. While he was there Boze finalized the design and using a CnC machine, they cut the wheels to the exact specifications.

The new rubber was too wide to fit. So, measurements were taken and all four of the wheel wells were flared to accommodate the larger meat.

Once the new rubber was mounted on the wheels, it became apparent that the tires and wheels were exactly what was needed to set off the car, but there was one challenge. They were too wide to fit in the wheel wells. So, measurements were carefully taken and all four of the wheel wells were flared to accommodate the larger meat. The work is subtle and it’s not really noticeable unless you look closely.

At this point, the rocker panels were modified to funnel even more air down the side of the car and into the air scoops to help cool the rear brakes. This effect makes the car look lower and longer than it really is and adds to the overall design.

The entire rear end of the car was modified, hand-fabricated and sculptured in metal to wrap around a set of new Mustang taillights with LED bulbs. The taillight covers were handbuilt to blend into the metal work until the lights are turned on.

All work is done in steel with the exception of the fiberglass nose and hood. Extreme Lighting HID headlights are frenched into the modified front fenders. No detail was overlooked. Once the hood was ready to be installed, Ring Brothers hood hinges were used to help offset the engine bay.

When Mike Markovich of Restorations and Reproductions installed and wired in the Auto Meter instruments, he added a special touch. All the instruments feature custom backlighting in red that is controlled by an electronic switch.

The bucket seats are tan glove leather as are the door panels. The tilt steering column is from Flaming River and the custom steering wheel is covered in the same glove leather as the rest of the interior. The carpet is brown German square weave.

Wanting a simple, tasteful design, the interior features a custom-built console and a Kenwood double-din touchscreen computer controlled sound system that features a 6.95-in. wide VGA color LCD display with LED backlight. Also, the unit has a motorized 7-Step Tilt-Angle “remote adjust” mounted in the dash.

Paying homage to the Shelby competition Mustangs in the mid-1960s, a rear deck was installed in place of the rear seat. Both the console and the rear deck were created by Restorations and Reproductions before it went to Guy’s Interiors for the final touch.

“The car is nothing short of spectacular,” Selland said. “Everyone involved did an outstanding job and I couldn’t be more pleased.

And with the awards received on its first time out, it’s a sure bet that the car has turned a lot of heads, each very impressed with what they saw.

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link