Lindsey Fisher

.

July 30, 2024

.

Buyer’s Guides

Lindsey Fisher

.

July 30, 2024

.

Buyer’s Guides

Photos by Rick Evans

Building a vehicle from the ground up is like no other experience. Sure, there are trials and tribulations along the way, but that feeling you get when you’re driving around in your finished ride knowing you did the majority of the work to create this beautiful rig of yours—ahh! There’s no feeling like it!

That’s exactly how Lloydminster, Alberta, Canada, resident Dave McKean feels about his 1977 GMC Jimmy. Having been in the automotive industry for 36 years and done partial builds before, Dave wanted to build a vehicle from the ground up, and he chose the ’77 Jimmy as the perfect platform.

Purchased in April 2018, this factory 2WD Jimmy was destined for great things. Having done extensive research on what he wanted to do to the truck, Dave started the tear down process the very next day after his purchase. Unfortunately, like many classic vehicles, the Jimmy had seen some life before Dave acquired it, which would require extensive metal work to fix rust and other body damage.

Knowing someone else was far more in tune with metal fabrication than he was, Dave sent the whole body off to DK Repair & Restoration in Marwayne, Alberta, for a full frame-off rotisserie restoration. This freed him up to do the remainder of the work to make this classic GMC his ultimate ride!

It gives me a lot of satisfaction while driving or showing it to know that I built it myself.

Wanting his truck to be perfect, Dave planned out every ounce of work to be done on the Jimmy. First was tearing the truck down to the frame so it could be C-notched, sandblasted, and powdercoated. The truck’s factory rear axle got the same treatment before being completely rebuilt to include a limited-slip differential and 3.73 gears.

Then came the suspension components. Dave opted to lower the Jimmy considerably—5 inches in the front and 7 inches in the rear, to be exact. He accomplished this with a combination of Classic Performance Products 3-inch drop coils and 2 ½-inch drop spindles up front, as well as re-arched stock leaf springs in rear, with the addition of a Belltech Flip Kit to relocate the truck’s rear axle to above the springs. He also outfitted the truck with Monroe shocks on all four corners, tubular control arms and a sway bar from Porterbuilt Fabrication up front.

In order to complete the rolling chassis, Dave also fitted the Jimmy with a new fuel tank featuring an Aeromotive Phantom in-tank pump and new fuel lines. Wilwood disc brakes both up front out back were then added, as well as all-new lines to the calipers fed by a Wilwood master cylinder.

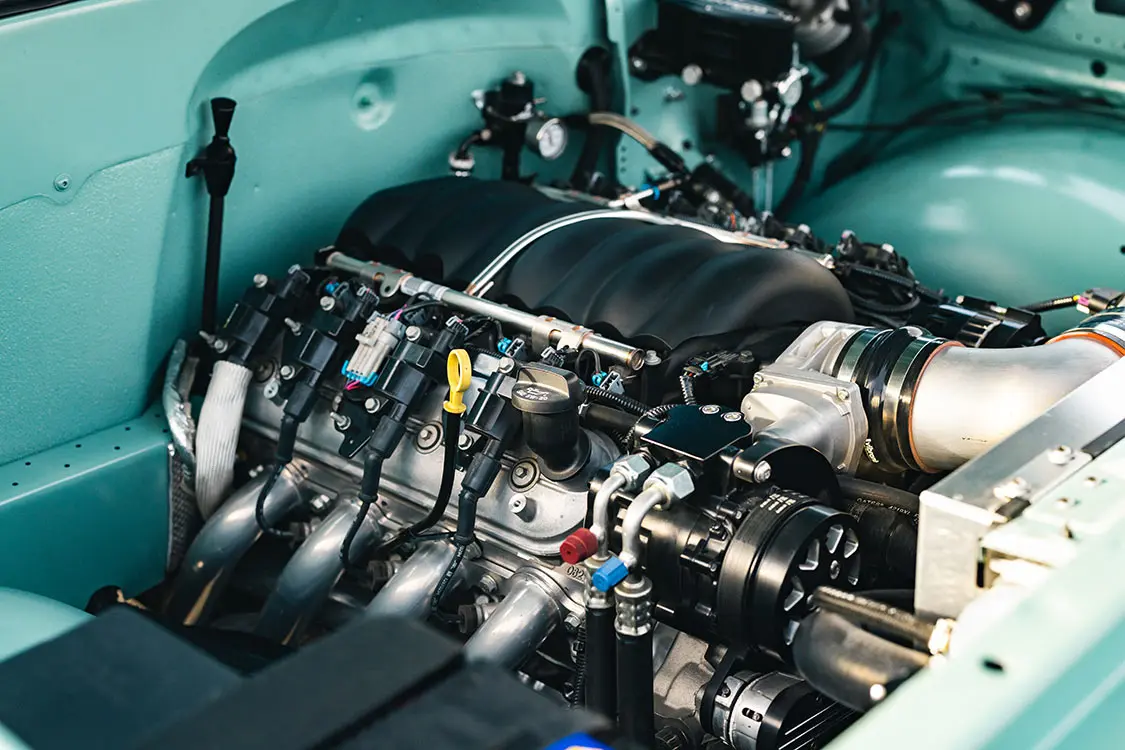

Having a rolling chassis, Dave moved on to focus on putting power under the Jimmy’s hood. For this, he entrusted the engine build to the pros at Chevrolet, opting for a crate Chevy Performance LS3 6.2L V-8 engine partnered with a Chevy-built 4L70e automatic transmission as part of Chevy’s “Connect & Cruise” powertrain system. Included in this package is everything you need to get your Chevy Performance engine purring and road-worthy, from the intake to the ignition system and computer.

To give the engine even more of an edge, Dave outfitted it with an American Autowire wiring harness on top of what Chevy provided, as well as an All American Billet serpentine belt system, Entropy LSX Swap aluminum radiator with dual Derale Performance fans, and Hooker ceramic-coated long-tube headers leading into a custom 3-inch dual exhaust system. Extra engine dress-up features, like All American Billet hood hinges, power steering reservoir, and coolant overflow tank were also added to match the belt system. All said and done, the Chevy Performance package offers the Jimmy 495hp.

Once the engine was built out, the top and bottom halves of the Jimmy were reunited at DK Repair & Restoration. Once the fully restored, now completely straight and rust-free body was in place, it returned to Dave’s personal shop for the finishing touches.

The exterior of the Jimmy is absolutely stunning, painted in 1957 VW Turquoise and White PPG paint, and featuring Grote Industries LED headlights and a MAR-K exterior trim kit. The interior of the truck is just as gorgeous, featuring the truck’s original seats that Dave reupholstered himself, set off by Buckskin carpet and floor mats from Auto Custom Carpets over a coat of LizardSkin sound deadening material.

The interior also features Dakota Digital VHX Series gauges and a Forever Sharp steering wheel, along with creature comforts like a modern sound system and air conditioning compliments of Custom Autosound, JL Audio, and Vintage Air components.

“We get tons of comments on the stock looking interior with the factory original seats, as well as how clean and tidy the engine bay looks,” Dave told us. Certainly one heck of a nice looking classic Jimmy, we understand why so many people are drawn to this beautiful GMC.

Running and driving, the Jimmy was completed in August of 2020—just over two years and four months from the day it was purchased. Three months later, it received its American Force VF498 wheels, which were installed with Toyo Proxes ST III rubber, just before the first snow of the season fell in Dave’s hometown.

Since then, the truck has gotten plenty of use, a lot of which it has seen in Chandler, Arizona where Dave and his wife Bonnie spend their winters. There, Dave takes the Jimmy to shows like Goodguys in Scottsdale and Dino’s Get Down, as well as plenty of cars and coffee events throughout the winter months.

“I know a lot of people buy trucks that are built for them by a professional shop, and that is fine,” Dave told us about the build of his Jimmy. “[But] I just wanted to be able to build my own. The only thing I did not do is the paint and bodywork.

“I have built and worked on some oval track race cars in the past, as well as a partial build on my 1967 C10, so I figured I would do a complete build,” he said. “It gives me a lot of satisfaction while driving or showing it to know that I built it myself.”

Owner

Chassis & Suspension

Wheels & Tires

Engine & Drivetrain

Body & Paint

Interior & Stereo

Share Link