John Mata Jr.

.

June 05, 2023

.

Buyer’s Guides

John Mata Jr.

.

June 05, 2023

.

Buyer’s Guides

You’ve most likely seen this ’75 Chevy dually around at a show or online somewhere and have had an instant reaction to what you were looking at. It’s a very polarizing truck, and there’s a lot to take in. Most people love it, but then there are those on the other side of the fence who absolutely do not like it—mainly due to the “sleeper” section of the back cab. Just for the record, we dig it. Obviously.

Chris Stoughton of Lubbock, Texas, built this truck from the ground up from parts and pieces from a multitude of donor pickups he had to purchase along the way for various components and panels that were completely rotted out. From the start, Chris wasn’t interested in piecing together something to please the masses. He always likes to stop and remember to keep his own interest and taste at the forefront of any of the custom vehicles he has built for himself since his high school days.

The dually was actually sourced locally in Lubbock. Chris had a friend who was looking to sell it as basic roller with no engine or transmission. The truck was in rough shape when he bought it, but Chris knew it had some potential. A week later, he then scored an ’89 GMC Suburban for its front clip, 454 engine and trans, along with its doors.

“I’ve always liked ’80s GMCs, so I figured I could do a complete frontend swap for the dually,” Chris says. “I also swapped the GMC doors for the Chevy doors so I could have factory power windows and locks when it was finished up.”

Aside from those transplanted GMC parts, Chris also had a ’61 Chevy C20 cab parked behind his shop that he pulled pieces from to use on the dually as well.

With the right tools, the willingness to learn, and a good work space, you are only limited by your imagination and skill level.

“The only good sections of that thing were the roof and the back of the cab. Oh, and the dash was still good, too,” he says jokingly. “As a goof, I cut the roof and the back of the cab off and sat it on the bed of the dually as a sleeper. The more my close friends looked at it, the more it became a part of the truck, so we made structural mounting frame for it, then fabricated sheetmetal for the area where the doors were.”

Little did Chris realize how controversial this modification would turn out to be among the truck’s online audience, as he was uploading photos and info of the build as he was making progress on it on multiple online truck forums.

“Later on, we put a wing on the sleeper for even more fun”, he adds. “People were so confused by where we were going with this part of the build, but that sleeper portion just looked too cool and uncommon to not make a permanent part of the project—plus, it gave me more room to stash gear for the shows I’d be traveling to in the future.”

At this point, it should be evident that Chris is a talented and very creative guy but he was the first to say that he did hit his struggles along the way.

“There wasn’t much information on how to modify 1-ton trucks out there when I started the build,” he admits. “People really didn’t use Facebook for stuff like this, and Instagram wasn’t even on the map yet. Also, the guys who had built these types of trucks then were very tight-lipped on what it took to build one, so my wife encouraged me to start a blog-style thread online to hopefully help others who were also trying to figure these trucks out as well.”

The coolest part of this has been getting compliments from other builders whom I admire, which makes all of those hard hours in the shop worthwhile.

Slowly, Chris found his way around the truck, and what he couldn’t figure out by talking to other builders, he had to make and do on his own.

“I’ve been customizing vehicles since I was a kid,” he adds. “This was mostly due to not having much money growing up. If I wanted something cool to drive I had to build it myself. This taught me to invest in tools and also do a lot of research before hacking things up. With the right tools, the willingness to learn, and a good work space, you are only limited by your imagination and skill level.”

Chris initially imagined the dually ‘bagged and sitting as low as possible, and to make this a reality, he modified the existing GMC frame quite a bit and adorned it with 3,800-pound ‘bags all around and wired up an Accuair eLevel control system. He installed a ThorBros HD 2-inch 4-link, as well as fabricated a one-off Watt’s link for the rear of the chassis for a slammed stance and excellent ride quality overall. Chris then wanted to see semi wheels on the dually, so he got a set of 22.5-inch Accuride Accu-Lite that that he proceeded to paint 1970 Chevy Ochre yellow to add a nice throwback appeal to the project.

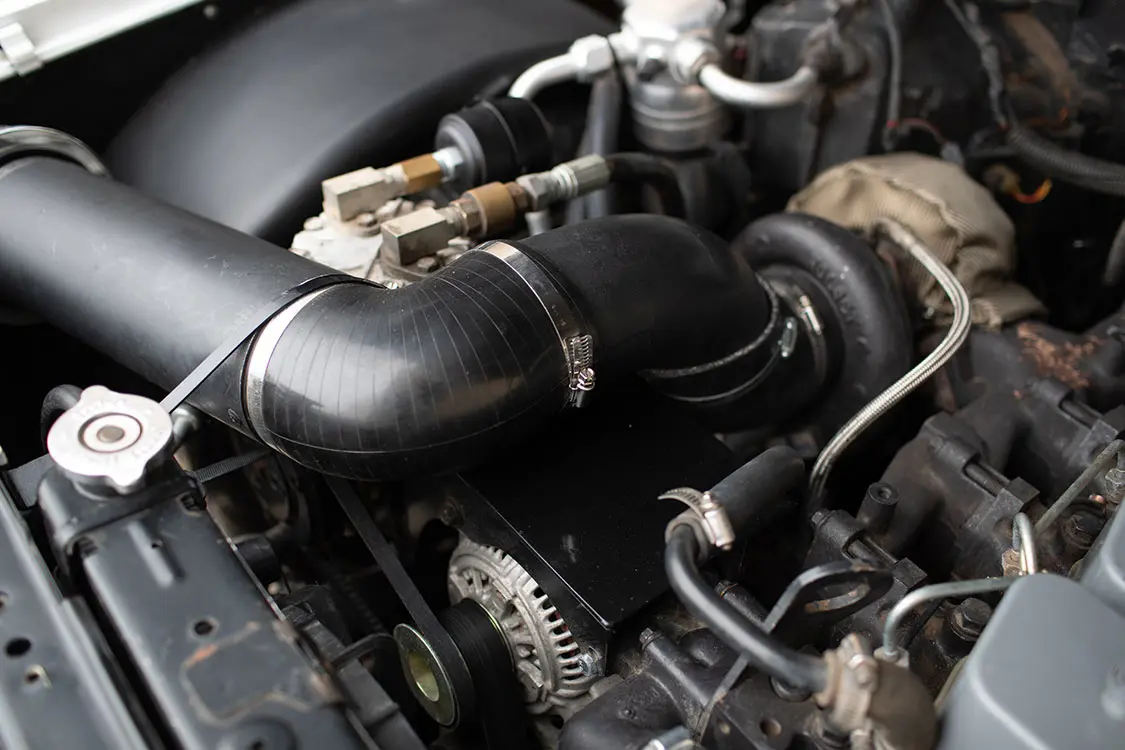

Another facet of the dually project Chris wanted to tackle was to replace that 454 engine with something a little more interesting. He chose to go diesel, and selected a 1991 I-6 5.9L Cummins mill that he rebuilt, along with a Dodge A518 transmission of the same vintage that he installed using custom engine and trans mounts that he designed and built himself.

Moving onto the exterior, Chris already had the frontend swap and sleeper cab fabbed up and ready to party, but he was looking to do next was simply change the truck’s color. While that sounds like a simple enough next step in the build process, Chris just knew that he could do something different without breaking his budget for the build.

“The price of paint was going through the roof at the time I was ready to paint ,” he says. “I decided to see if vinyl wrapping it myself might be a good alternative since it was a heck of a lot cheaper than paint. I was up for giving it a try at least, but it went on better than expected. I first used a blue colored wrap from VVivid Vinyl, but ended up changing it up to the matte white color that it is today.”

While this dually might not be everybody’s cup of tea, Chris built the truck he wanted largely on his own. That alone deserves a ton of respect.

“This project has helped me improve my skills and confidence level, and it allows me to get to know a lot of good people across the US,” Chris states. “I’ve never been worried about what the public was going to say about my truck, and didn’t do it for the trophies. The coolest part of this has been getting compliments from other builders whom I admire, which makes all of those hard hours in the shop worthwhile.”

Chris Stoughton

Share Link