Provided by ARP

.

September 11, 2024

.

Feature Stories

Provided by ARP

.

September 11, 2024

.

Feature Stories

Overlanding often involves going off the beaten path to places less traveled. As such, reliability is a primary concern. And while most overlanders don’t employ a fully race-prepped 4×4 that’s ready for the Baja 1000, there are several key areas where off-roading expertise comes into play.

Most everyone interested in any form of racing has heard of ARP, the company that has developed superior quality fasteners for virtually any applications, and manufactures them totally in-house at their California facilities to assure total quality control. While many race cars and trucks are assembled almost totally with ARP chrome moly steel fasteners, there are a number of areas where they make sense for normal off-road use.

Let’s start with wheel studs, which are subject to constant abuse. In addition to ARP’s wheel studs being rated at 190,000 psi tensile strength (some 63% stronger than common Grade 5 hardware), they come in a variety of lengths that are ideally suited for use with aftermarket wheels. It’s important that the stud length is such that it protrudes out of the lug nut by several threads (some racing associations deem it necessary for the stud to protrude a distance equal to its diameter, others call for protrusion of at least half the stud’s diameter). ARP wheel studs are also cadmium plated for extra durability.

Needless to say, it’s important that the lug nuts be properly torqued to apply the necessary clamping load. In addition to the threads being clean, applying ARP Ultra-Torque fastener lubricant ensures getting between 95-100% of the desired preload on the first “pass” of the torque wrench. Other lubricants have been found to be inconsistent, and require several tighten/loosen/tighten cycles to mitigate friction.

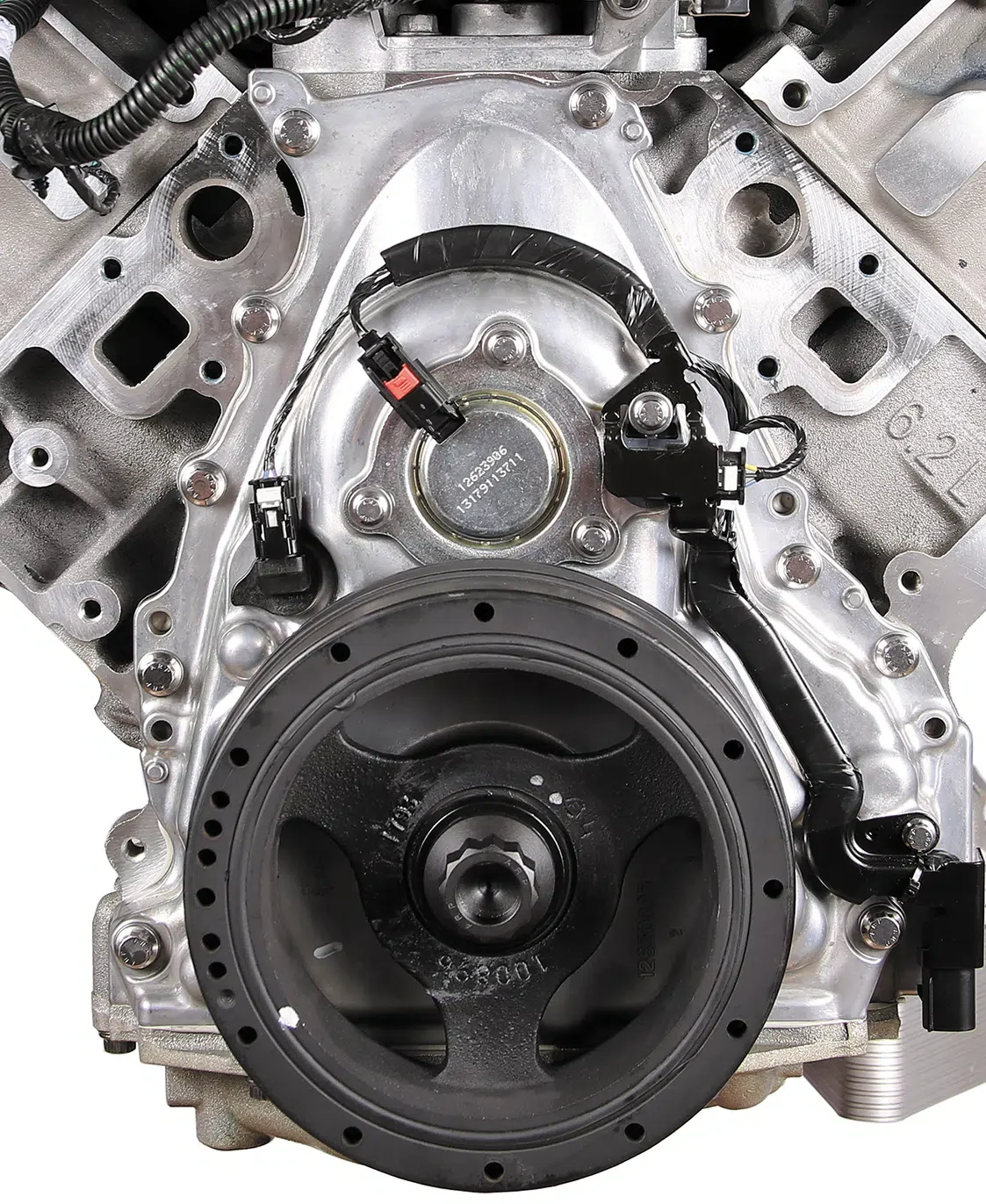

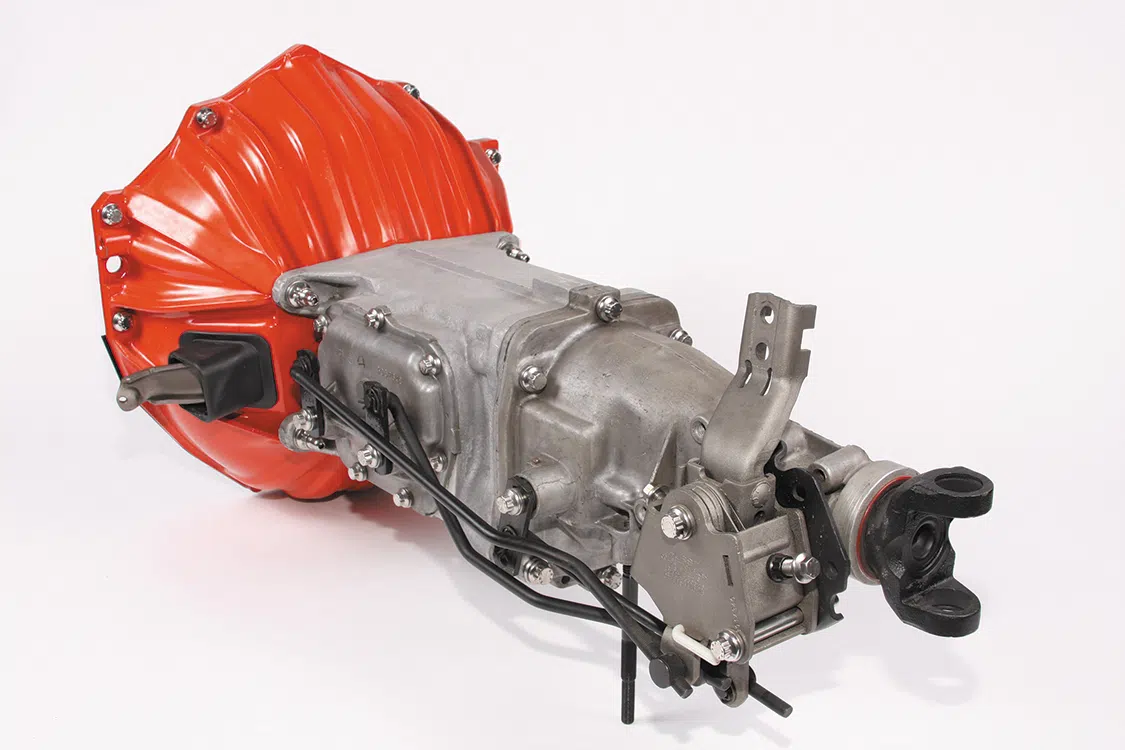

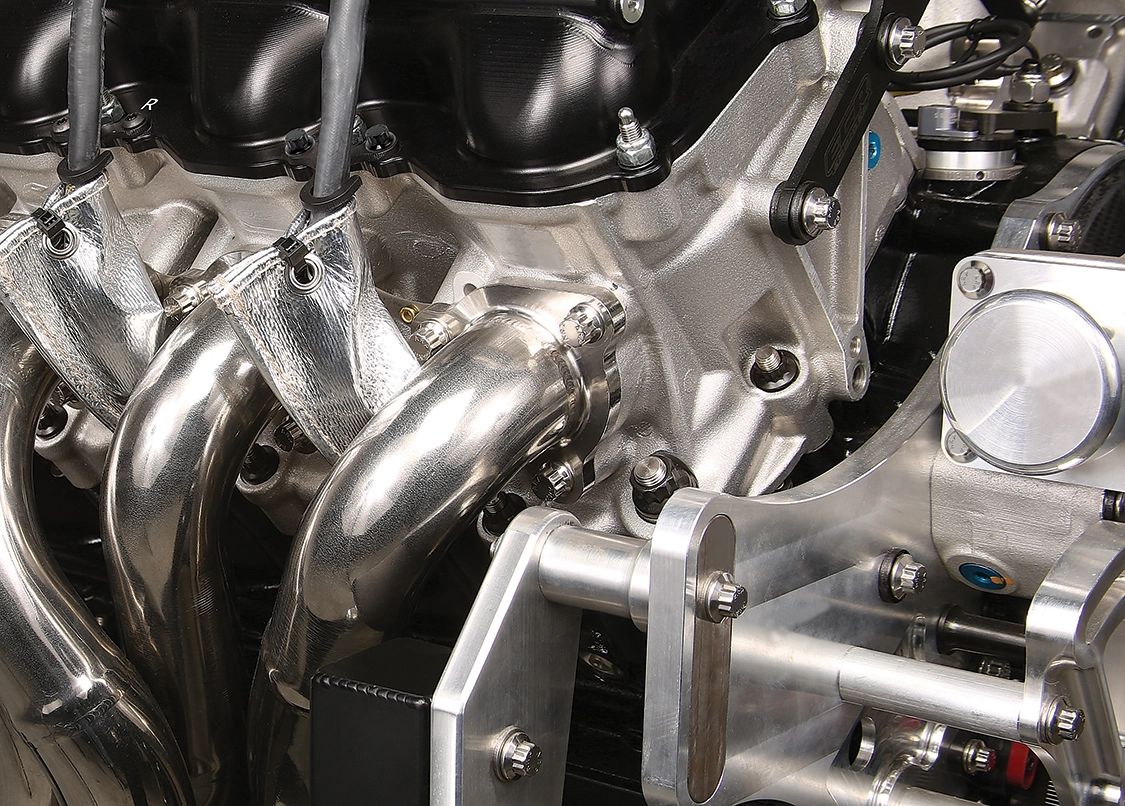

Additional driveline-bolstering fasteners include specially designed flywheel and flexplate bolts that feature a large 12-point head and an enlarged shank that provides improved register. They are made of chrome moly steel and substantially stronger than Grade 8 hardware. Similarly improved bolts are available for securing clutch plates and torque converters.

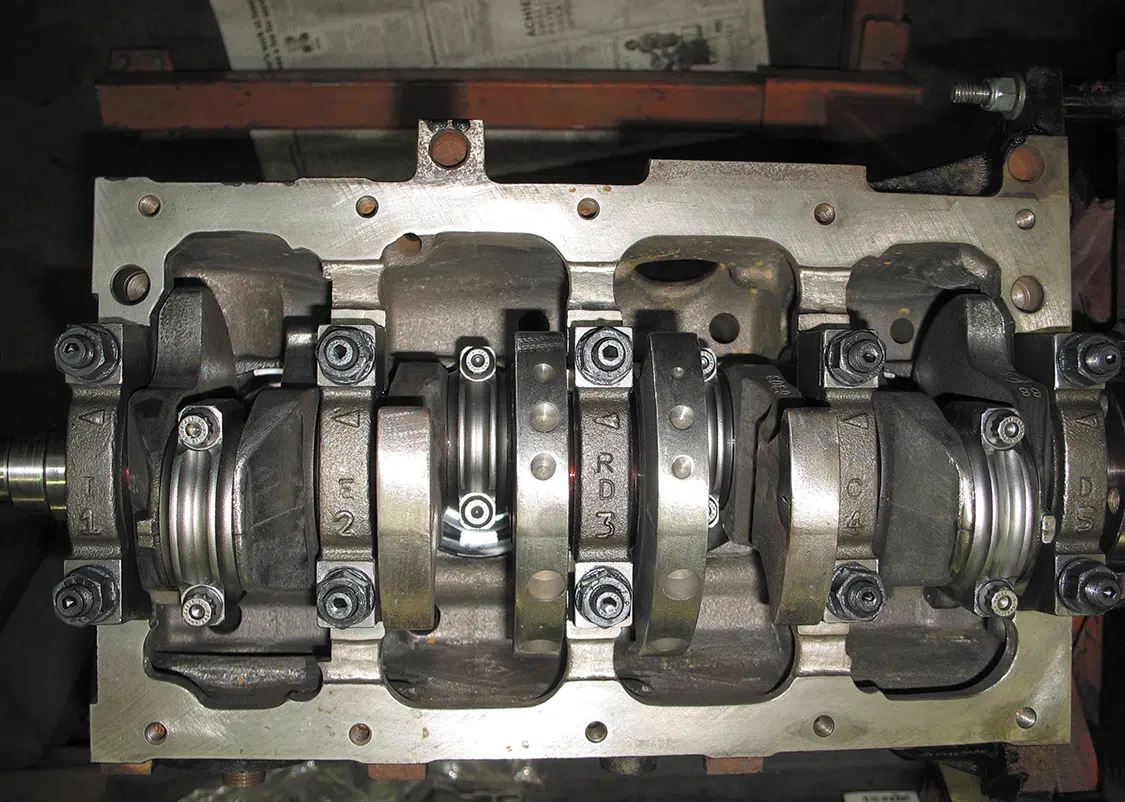

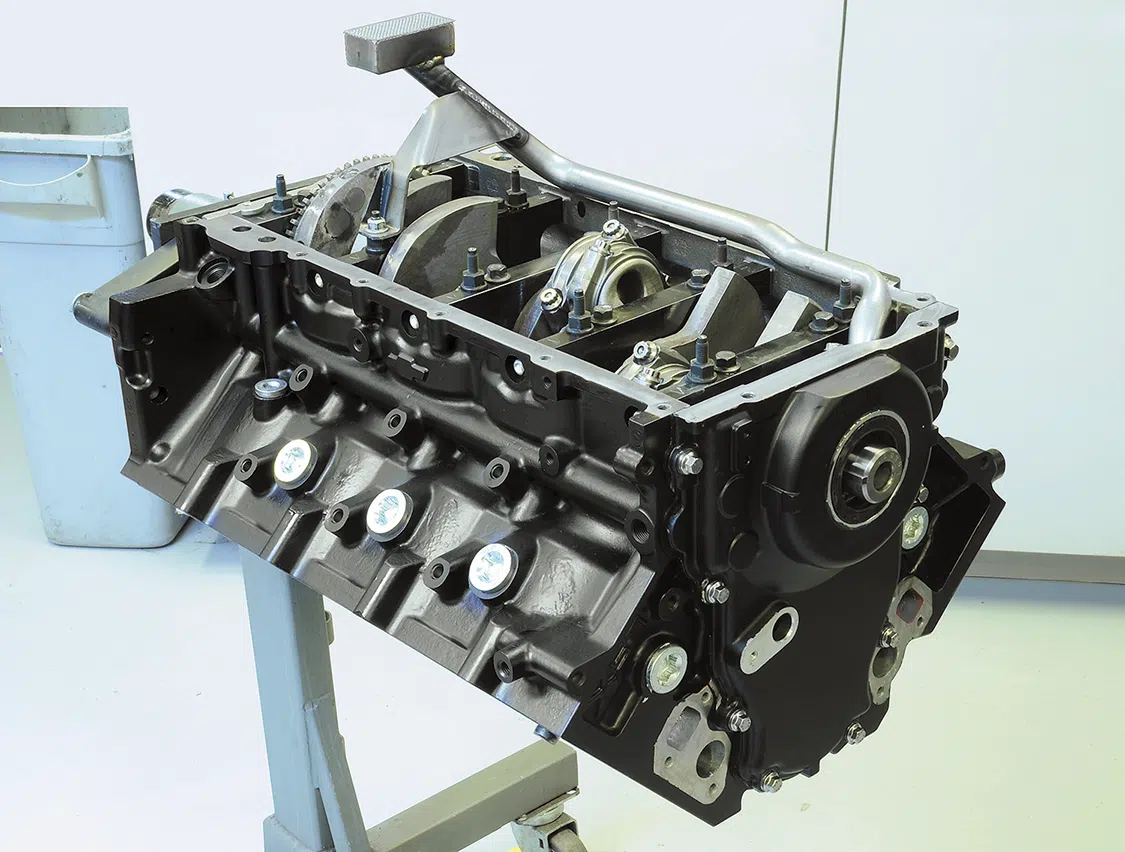

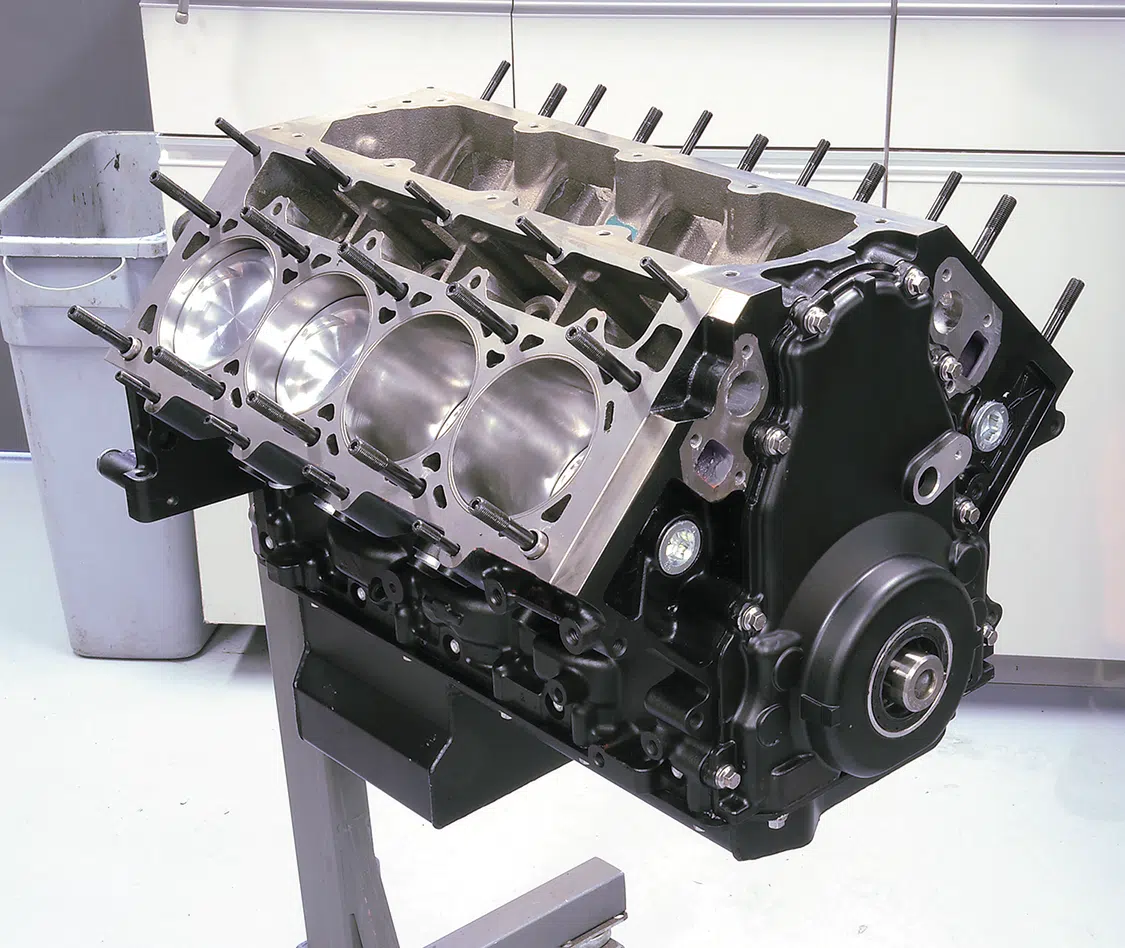

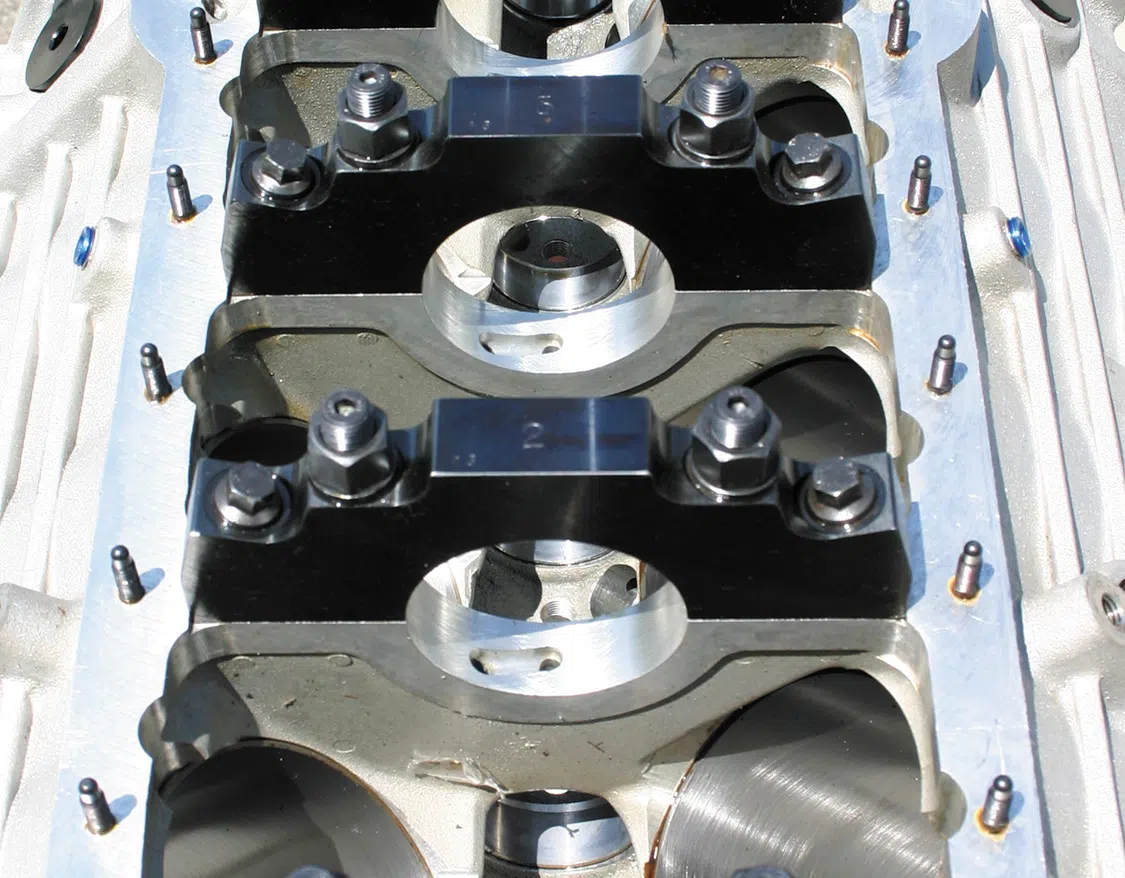

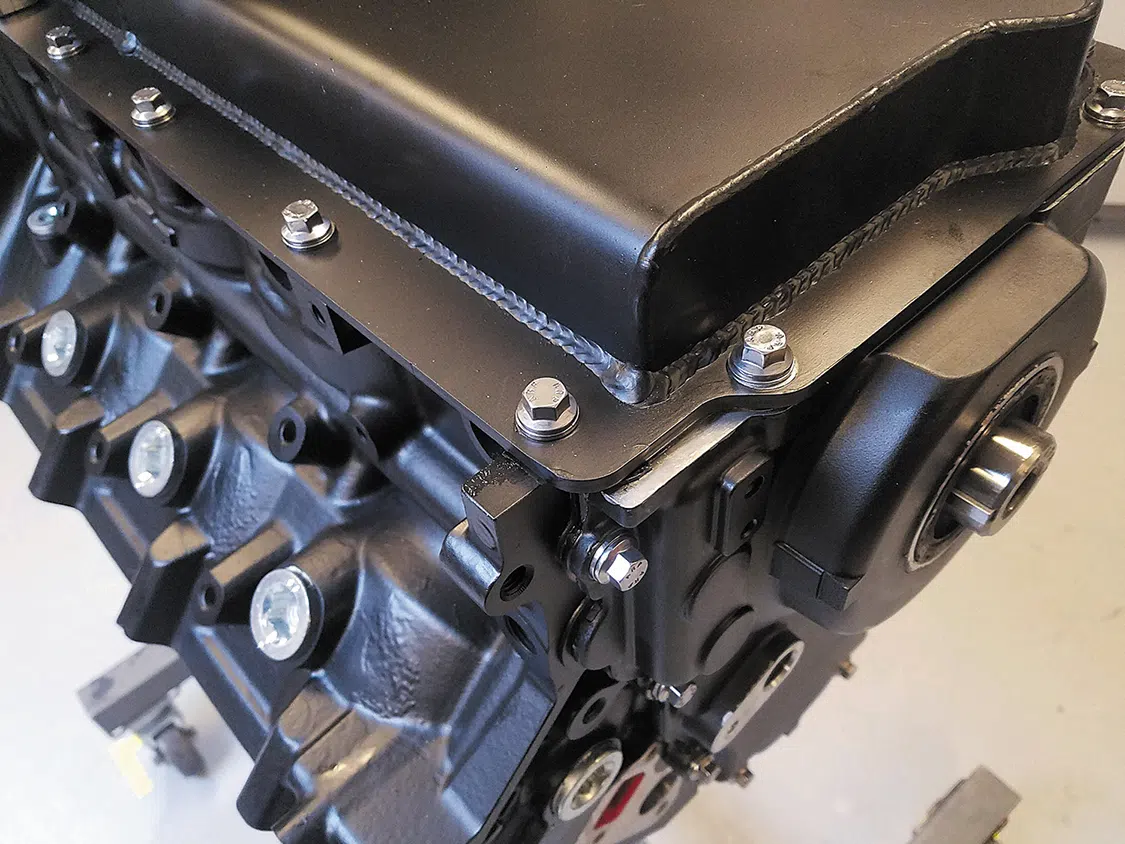

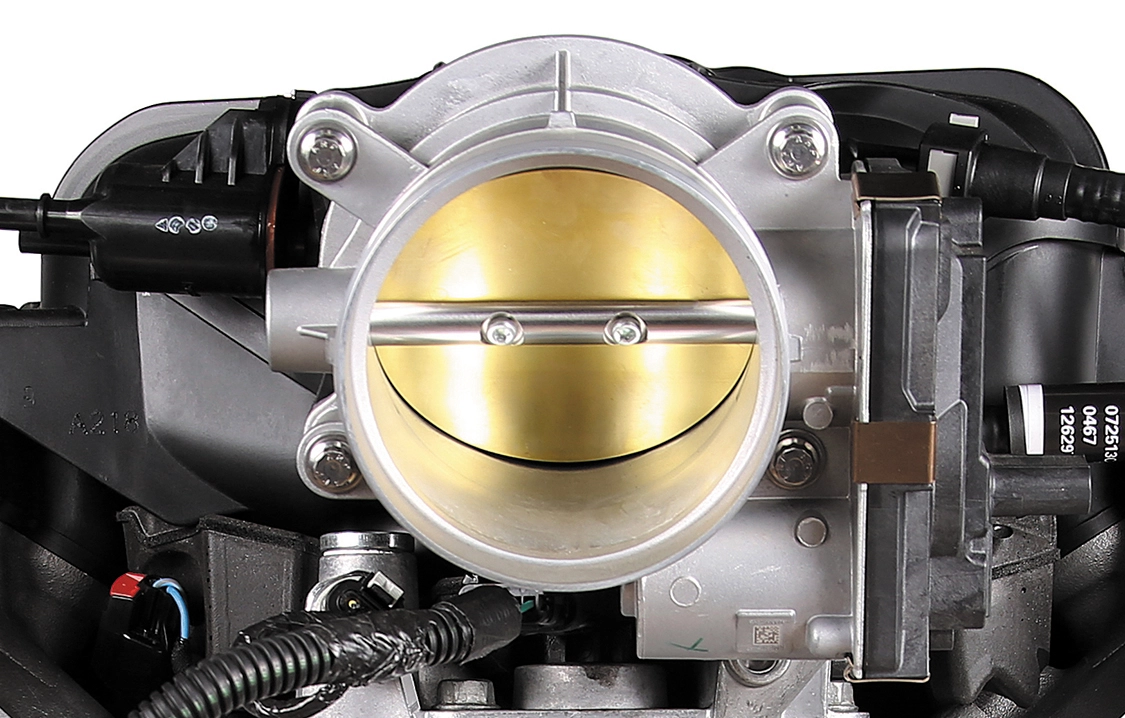

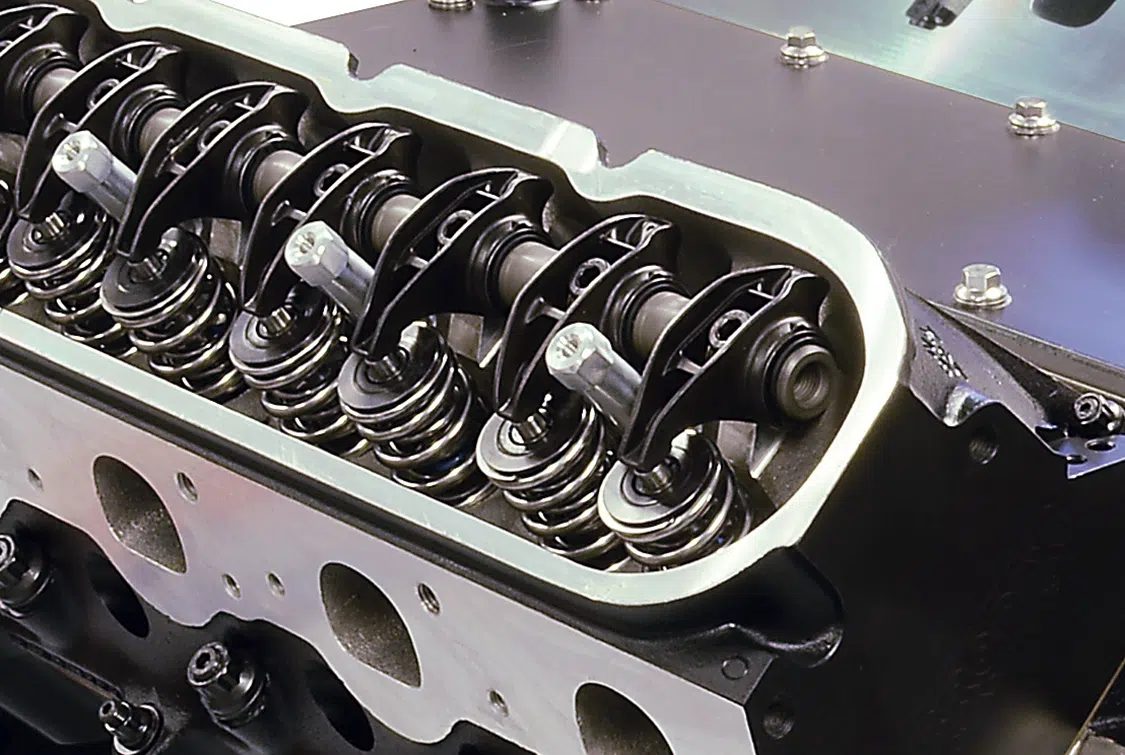

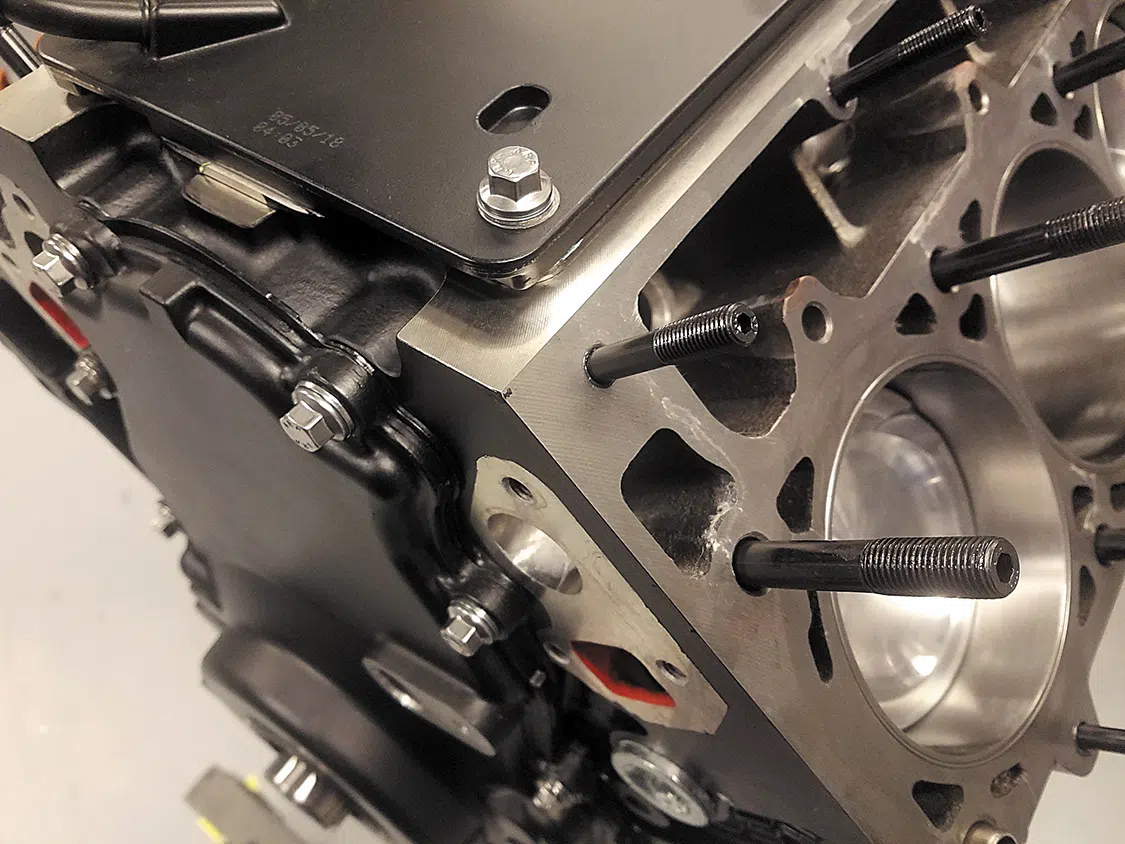

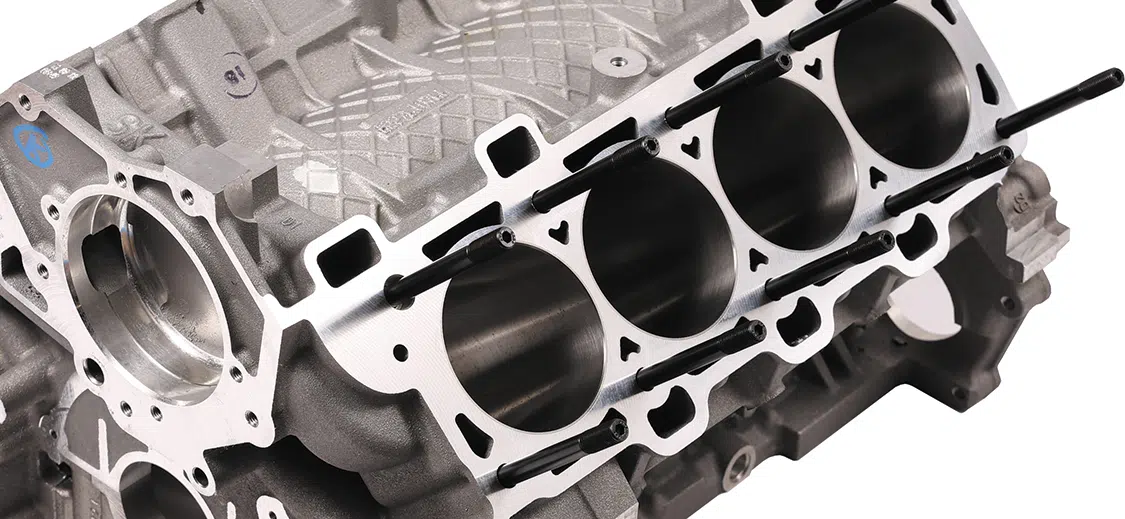

Critical engine fasteners are, of course, the mainstay of ARP’s business. It’s important to point out that most vehicles for the past 30-plus years have been manufactured using TTY (torque to yield) fasteners. While they are certainly adequate for normal use, they are yielded by design and should never be reused. The addition of power-adders to an engine can also compromise OEM fasteners. It should be noted that all ARP head and main studs (or bolts), rod bolts, etc. are engineered to provide additional clamping force and have an extra margin of safety.

ARP’s polished stainless steel fasteners can be employed in a number of ways on an overlanding vehicle or trailer, such as attaching racks and other accessories. They are manufactured from a proprietary alloy that’s rated at 180,000 psi tensile strength —fully 20% stronger than premium Grade 8 hardware. More importantly, they are virtually impervious to the elements and will provide years and years of trouble-free service without rusting or corroding. They are available by size in handy 5-packs and range from small #10-32 x ½-inch long hex-headed or 12-point bolts to big ½-inch o.d. by 6-inch long bolts offered in SAE fine and coarse thread, as well as Metric sizes. Black oxide finished 8740 chrome moly bolts, also rated at 180,000 psi, also available in all sizes.

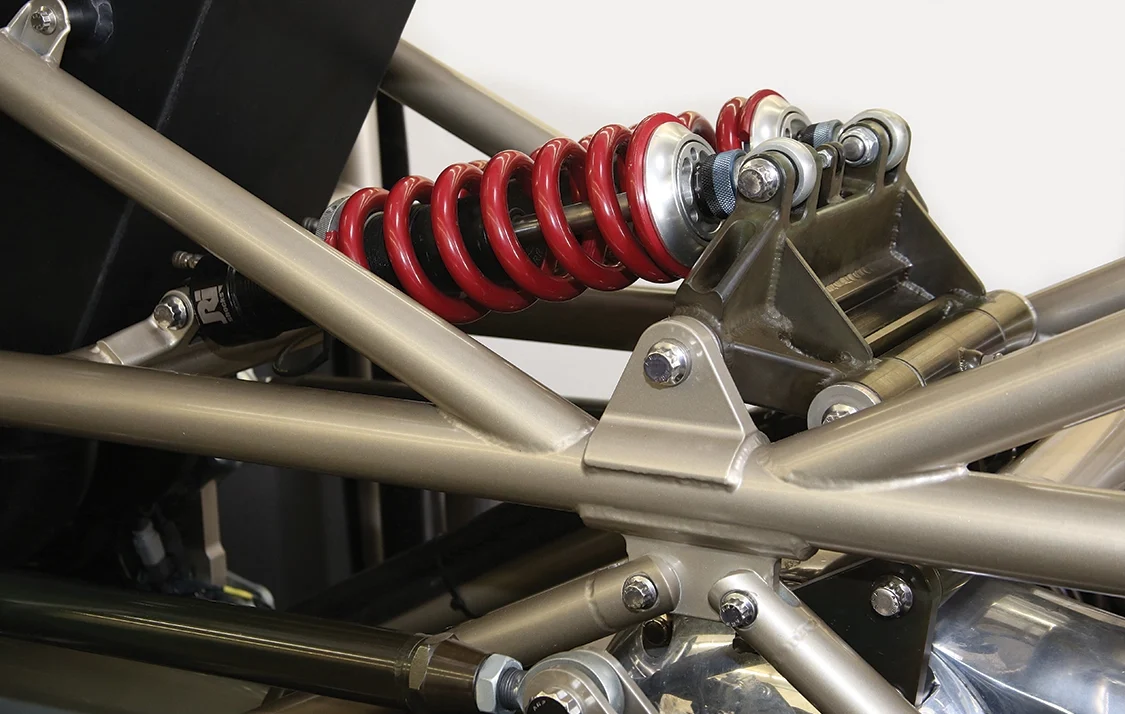

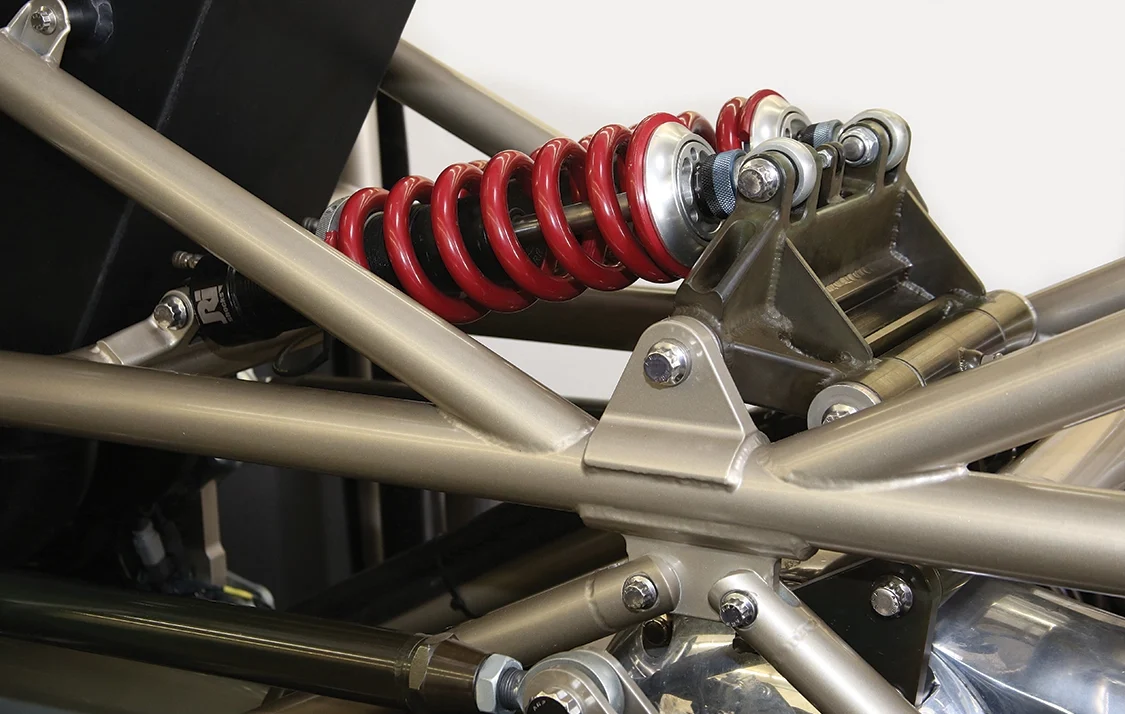

Larger sized bolts, 3/8-inch, 7/16-inch and 1/2-inch in diameter merit consideration for mounting critical suspension components, such as shock absorbers, sway bars, control arms and the like. Factory hardware is subject to fatigue, and in some parts of the country corrosion is the culprit for fastener failure. There are SAE (Society of Automotive Engineers) case histories of suspension problems related to failed fasteners.

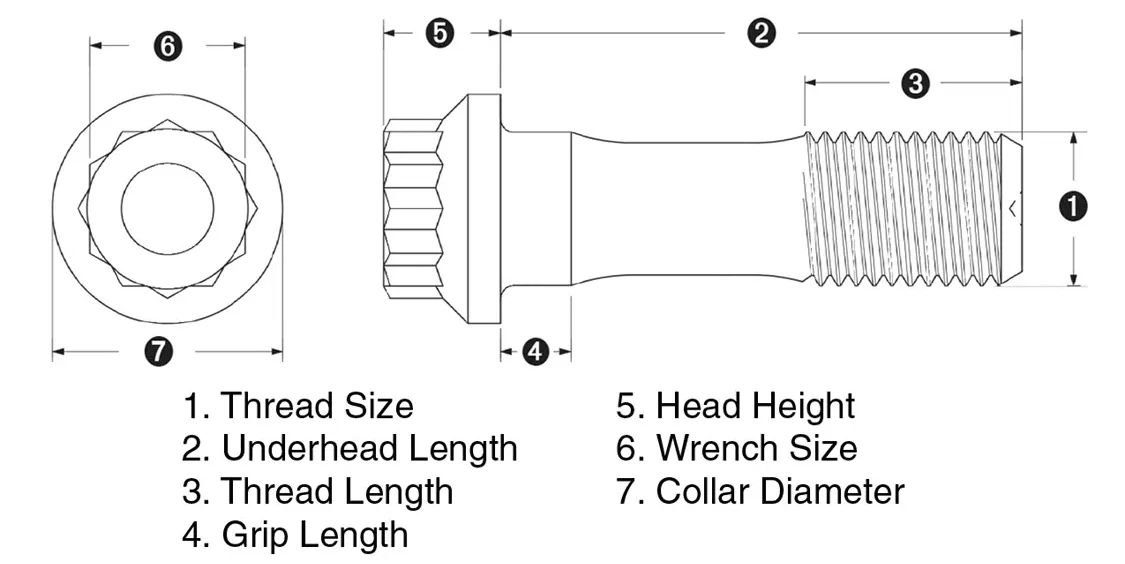

When procuring heavy-duty replacement bolts for suspension use it’s important to make sure all the dimensions are the same. This includes the shank diameter, underhead length, thread length and grip length. Other variables are the collar diameter, thread pitch, head type and height.

To augment its lineup of bolts and studs ARP also manufactures a full assortment of hex and 12-point nuts for all sized fasteners, including Nylon type self-locking designs. Don’t let your next adventure be thwarted by a failed fastener. Get reliability “insurance” with premium grade, Made In USA, nuts, bolts and studs.”

Source: ARP 1863 Eastman Ave. Ventura, CA 93003 ARP-bolts.com 800-826-3045

Editor’s Note: A version of this article appeared in TREAD Jan/Feb 2024.

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link