Tim Cachelin and The EVBG Team

.

November 01, 2024

.

Electric Vehicle Features

Tim Cachelin and The EVBG Team

.

November 01, 2024

.

Electric Vehicle Features

As the automotive world pivots towards a more sustainable future, interest in electric vehicles has grown significantly. However, for many car enthusiasts and everyday drivers alike, the prospect of purchasing a brand-new EV can be daunting due to high price tags. This has led to a burgeoning interest in converting existing internal combustion engine (ICE) vehicles to electric powertrains. But the pressing question remains: Can this conversion be done affordably?

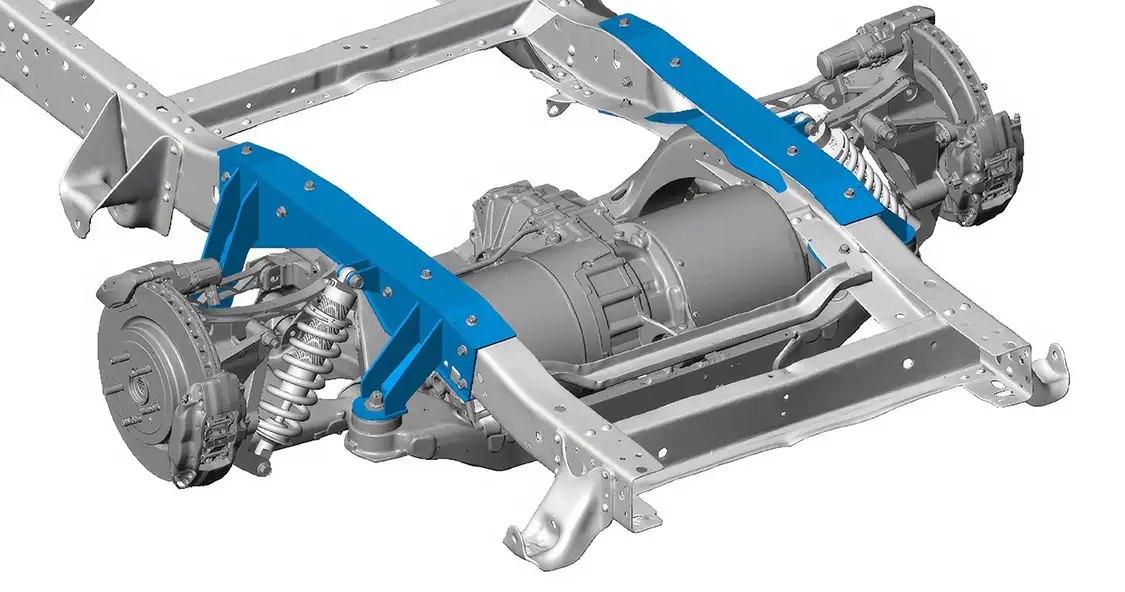

Converting a vehicle to an electric powertrain involves replacing the traditional ICE components with an electric motor, battery pack, and associated electronics. This process typically includes the removal of the engine, transmission, fuel tank, and exhaust system. In their place, electric motors, battery modules, inverters, and controllers are installed. While this might sound straightforward, the reality can be far more complex and cost-intensive.

The cost of an electric conversion can vary widely depending on the type of vehicle and the desired range and performance. Basic conversion kits, which include the essential components, can start around $8,000 to $10,000. These kits are becoming more comprehensive and user-friendly, making the conversion process smoother and more affordable. In some cases, these kits might take advantage of refurbished components, such as the Legacy EV Nissan Leaf conversion kit. Using reclaimed components from other EVs can drastically reduce initial investment and give the consumer peace of mind by using road-tested technology.

For those looking to convert larger vehicles or seeking higher performance and longer range, the costs can escalate quickly. High-capacity battery packs, more powerful motors, and advanced control systems can push component costs to $30,000 and beyond. In some cases, a fully converted EV can cost more than $100,000 for a premium option including installation. However, DIY enthusiasts with the right skills can save significantly on labor costs.

While it can be an investment, the potential for operational savings, environmental benefits, and the personal satisfaction of driving a custom-built EV are compelling factors.

Beyond the basic components, new solutions are addressing the additional expenses and challenges traditionally associated with conversions. Custom fabrication needs are being minimized by universal mounts and adaptable systems. Upgrading suspension and braking systems is becoming more straightforward with ready-to-install kits designed specifically for electric conversions. Plug-and-play kits are also hitting the market, drastically reducing programming and wiring costs.

Another significant factor is the regulatory and inspection requirements. Depending on the jurisdiction, a converted vehicle may need to undergo extensive testing and certification to ensure it meets safety and emissions standards. Fortunately, streamlined processes and increasing support from local authorities are making certification easier and less costly.

Several factors can help offset the investment in an electric conversion. Government incentives and rebates for EV conversions are available in some regions, reducing the financial burden. Additionally, the operational savings of an electric vehicle—lower fuel costs, reduced maintenance, and longer component life—can make a converted EV more economical in the long run.

Electric vehicles have fewer moving parts than their ICE counterparts, leading to lower maintenance costs. Brake wear is reduced thanks to regenerative braking systems, and there’s no need for oil changes or exhaust system repairs. Over the vehicle’s lifetime, these savings can be substantial.

For the mechanically inclined, a DIY conversion can be an even more affordable route. By sourcing components individually and performing the labor themselves, enthusiasts can significantly reduce the overall cost. Online communities and forums provide valuable resources and support for those embarking on a DIY conversion project. With technical knowledge, time investment, and a willingness to learn, the dream of a personal electric vehicle is within reach.

Converting a vehicle to an electric powertrain is an enticing prospect for those passionate about sustainability and technology. While it can be an investment, the potential for operational savings, environmental benefits, and the personal satisfaction of driving a custom-built EV are compelling factors. The landscape of electric conversions is evolving rapidly, making it more accessible and affordable than ever before.

The affordability of an electric conversion depends on the individual’s goals, budget, and willingness to navigate the technical challenges. As technology advances and more resources become available, the dream of an affordable electric conversion is becoming a reality for a broader audience. The electric conversion revolution is here, and it’s driving us towards a greener, more sustainable future one vehicle at a time.

Share Link