EVBG STAFF

.

November 27, 2023

.

Electric Vehicle Features

EVBG STAFF

.

November 27, 2023

.

Electric Vehicle Features

Hold onto your hats, folks, because we’re about to dive into a whole new world of battery lingo! But don’t worry—we’ll guide you through it all with simplicity. And once you get past the initial jargon overload, you’ll realize that energy storage devices aren’t actually rocket science. They are, however, fascinating once you start digging in.

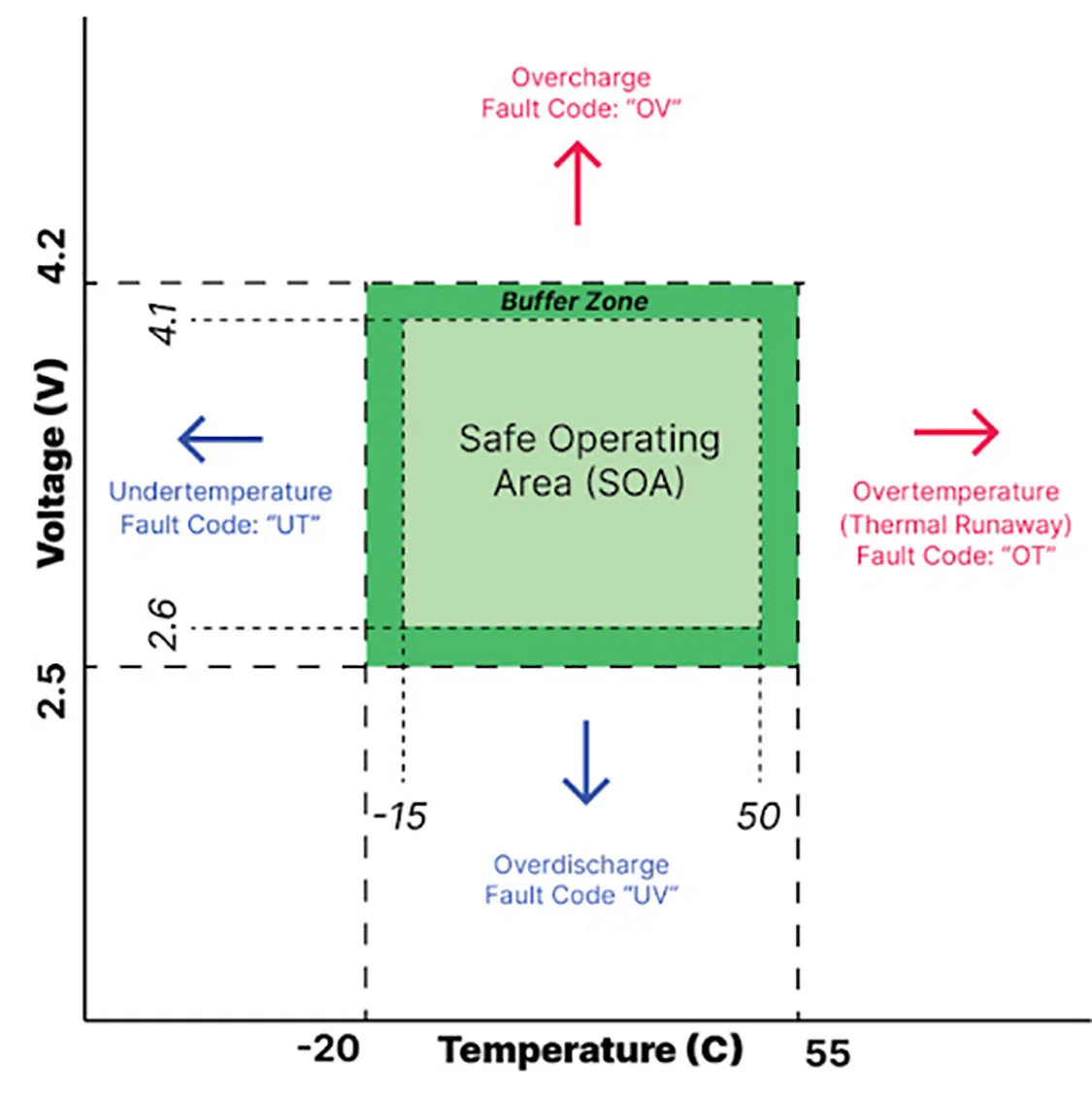

Voltage and temperature monitoring allow the Battery Management System (BMS) to make informed decisions and take proper actions to ensure battery cells stay in their SOA based on the battery manufacturer’s data specifications. The BMS should be programmed to keep the individual cell groups operating within the box of the SOA.

Thermistors are passive components that respond to a change in temperature by changing their resistance. They are equally distributed throughout a battery pack to ensure consistent temperature monitoring.

A battery management system is a unit that monitors and controls the battery pack health to ensure performance, safety, and long-term reliability. A BMS uses wires known as cell taps to monitor the individual battery cells in series and communicate with other systems accordingly.

Cell taps are placed after every series connection between battery cells to read their voltage. A healthy battery pack will display cell group voltages that are consistent and within the min-max voltage specifications for that cell chemistry.

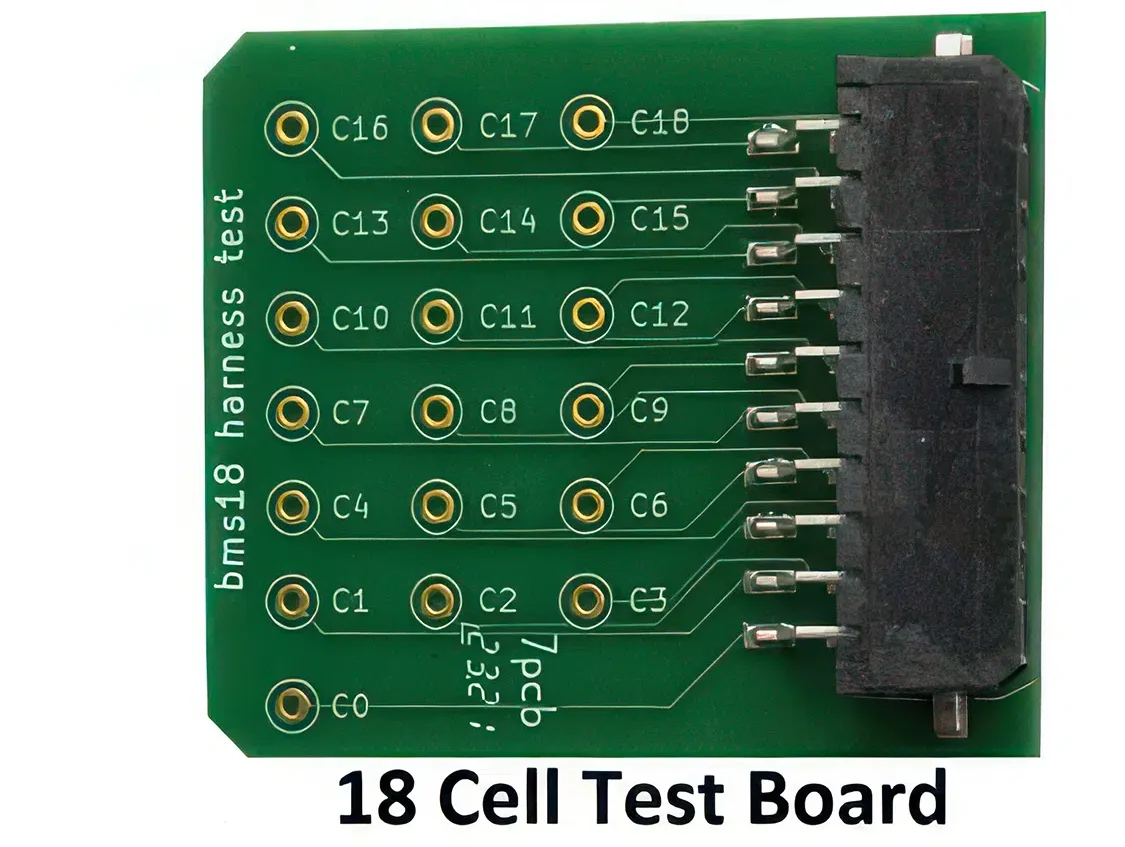

Used to verify that cells are connected in the proper order with the proper polarity. If the cell harness is not wired correctly, the BMS measurement board may be damaged. The harness tester connects directly to pack voltage, and so there may be up to 60 volts present on the harness.

Industry jargon for old-school EV conversions that used lead-acid batteries for their HV battery pack.

A communication protocol that enables Battery Management Satellites (BMSS) to communicate with the battery master controller (BMSC). IsoSPI is a “daisy-chain” protocol: Each device receives every message and forwards it downstream.

The upstream interface. Information is sent to downstream components from this connection.

The downstream interface. Information is received from upstream components from this connection.

Lithium-ion NMC cells are the building blocks of most modern battery packs due to their leading energy density, which allows them to provide more energy storage with minimal weight. They typically have a nominal voltage of 3.6-3.7V and an operating range of 3.0-4.2V per cell. But this energy density comes at cost—namely higher market prices and less cycle life compared to other technologies.

LFP battery cells are less energy dense than NMC cells but are a cheaper alternative that boasts a significantly longer cycle life and increased stability. They typically have a nominal voltage of 3.2-3.3V and an operating range of 2.5-3.65V cell.

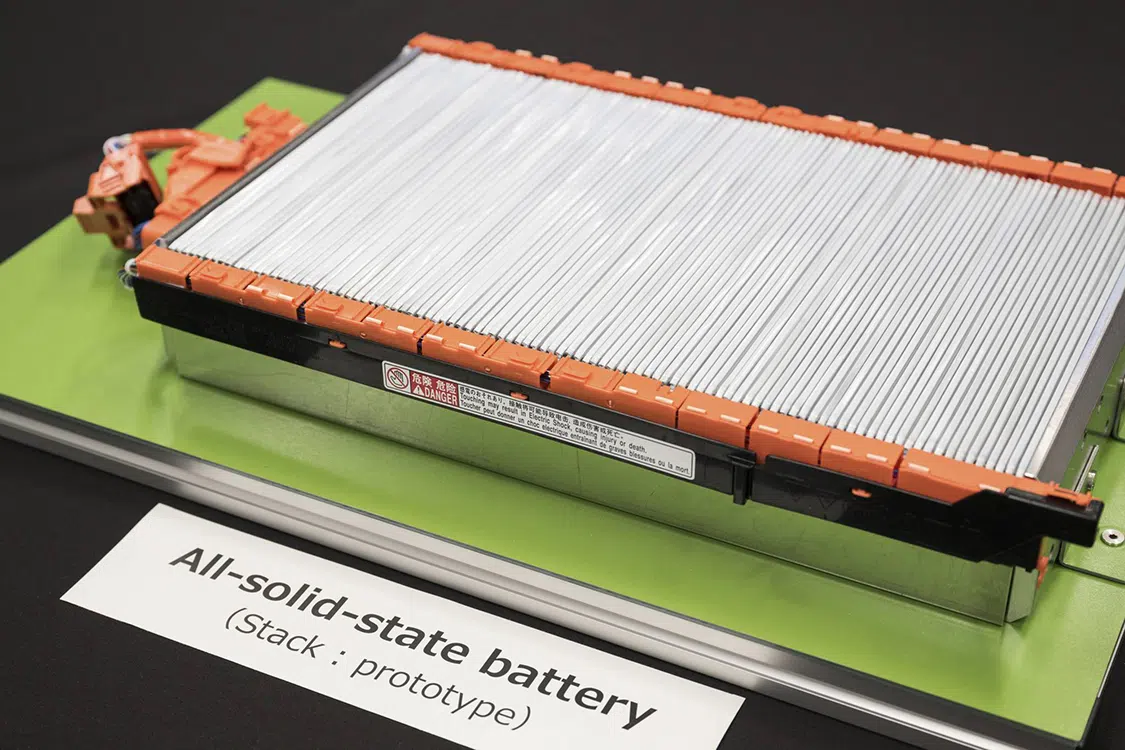

A battery technology that uses a solid electrolyte instead of the flammable liquid electrolyte solution in lithium-ion batteries. Solid-state batteries are still mainly in development, but once commercially available, they promise to significantly improve battery energy density and safety.

Share Link