JEFF ZURSCHMEIDE

.

June 03, 2022

.

All Feature Vehicles

JEFF ZURSCHMEIDE

.

June 03, 2022

.

All Feature Vehicles

When you’re planning the performance engine of your dreams, chances are good that you’re thinking about block selection, displacement, compression ratio, carb versus injection and whether to use forced induction. You’re not likely thinking about pulleys, alternators and pumps, but before you can fire off that engine for the first time, you have to get those parts in order.

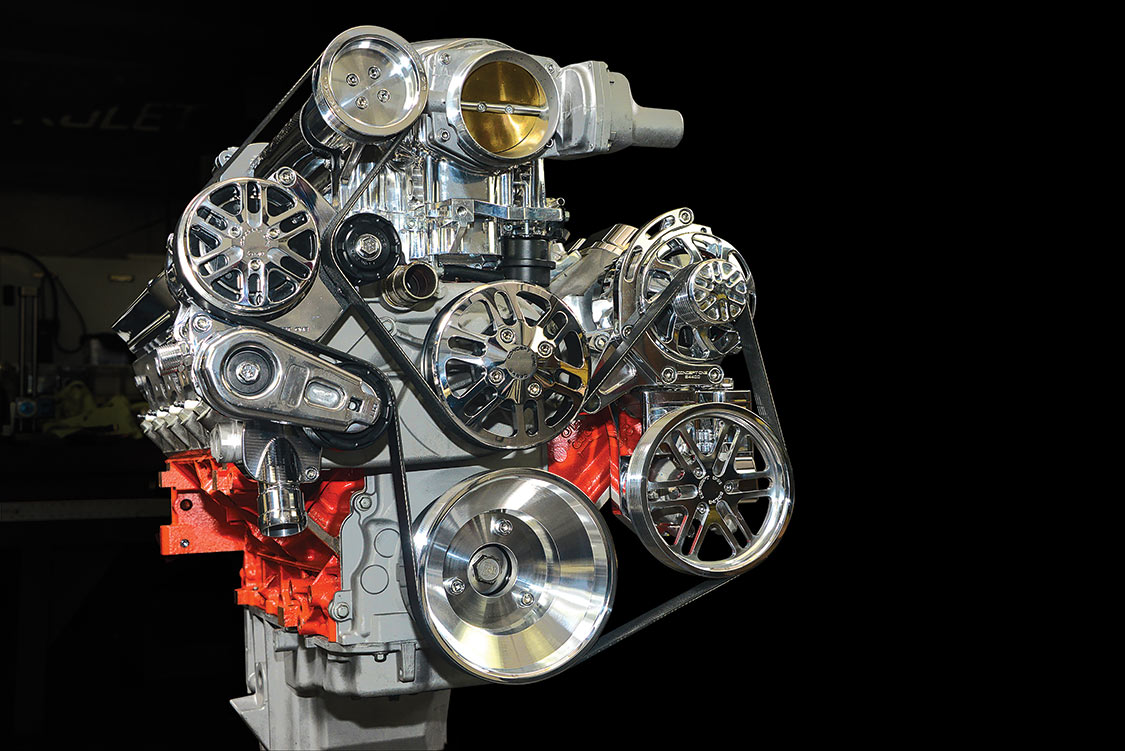

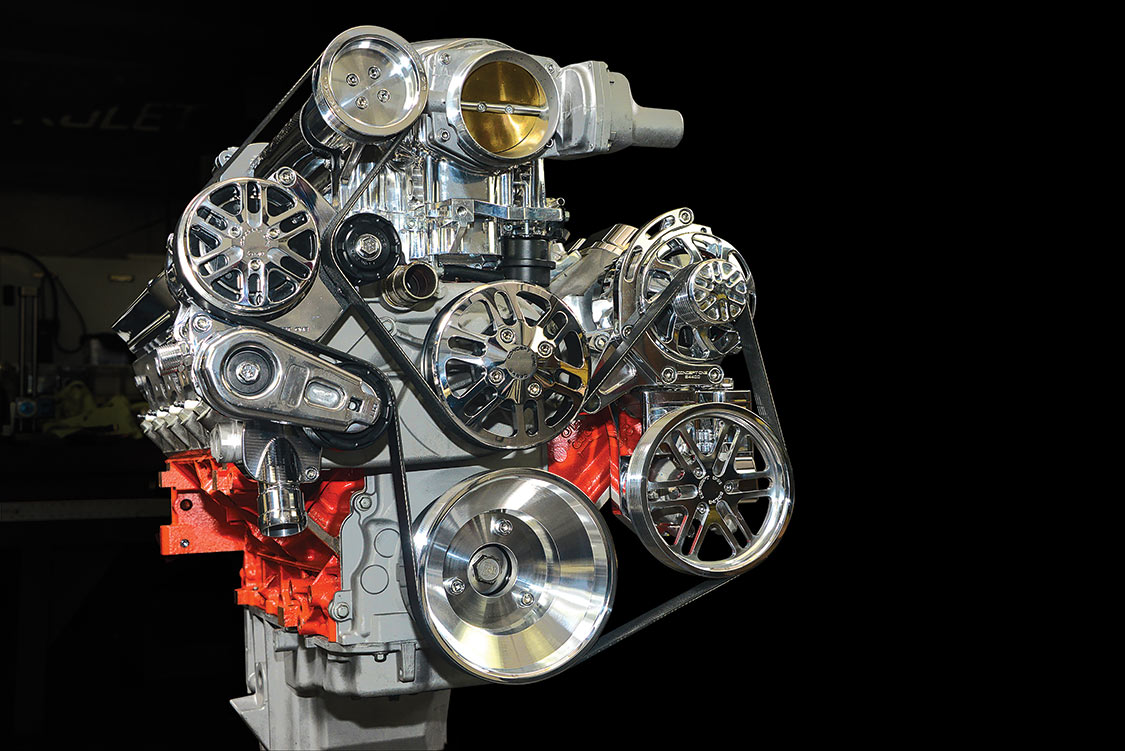

The challenges are significant. When you build a custom engine, there’s no guarantee that everything’s going to line up or that each component will take the same kind of drive belt. Think about it—you have the crank, the alternator, air conditioning compressor, power steering pump, water pump and maybe the supercharger. What are the chances of all those pulleys being the same? Even worse, what are the chances that they’ll all look good together?

Brothers Kevin and Randy Redd took note of the great pulley quandary a few years ago and set about to create the solution.

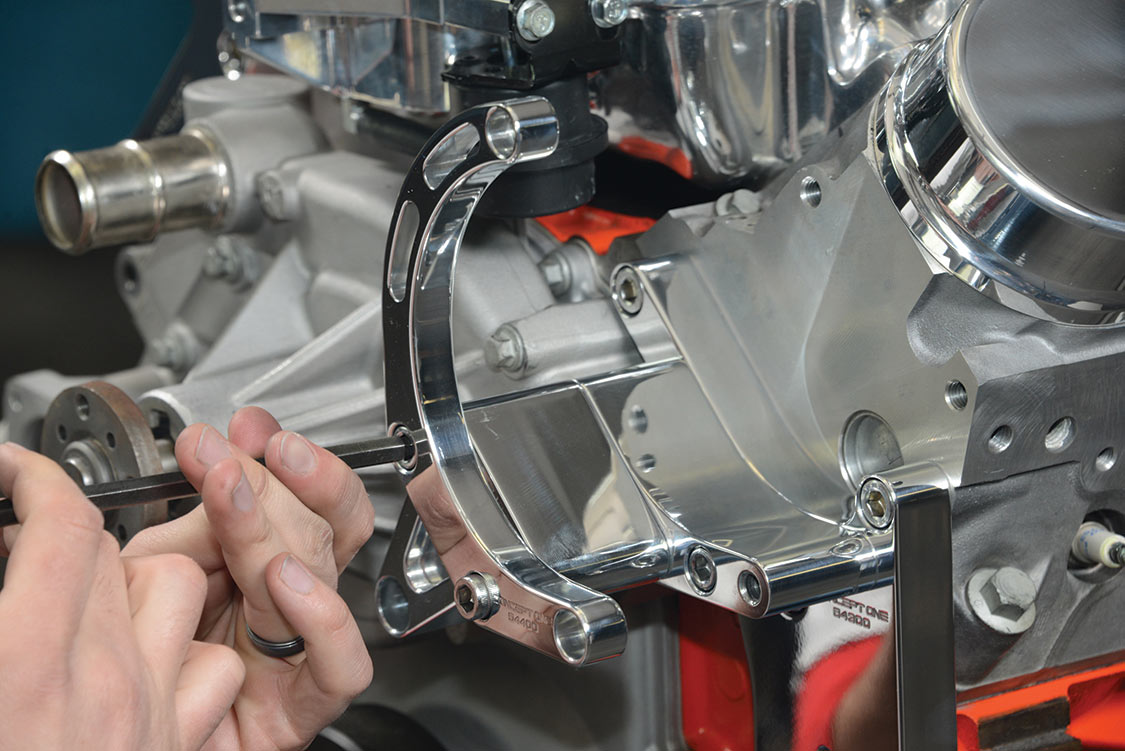

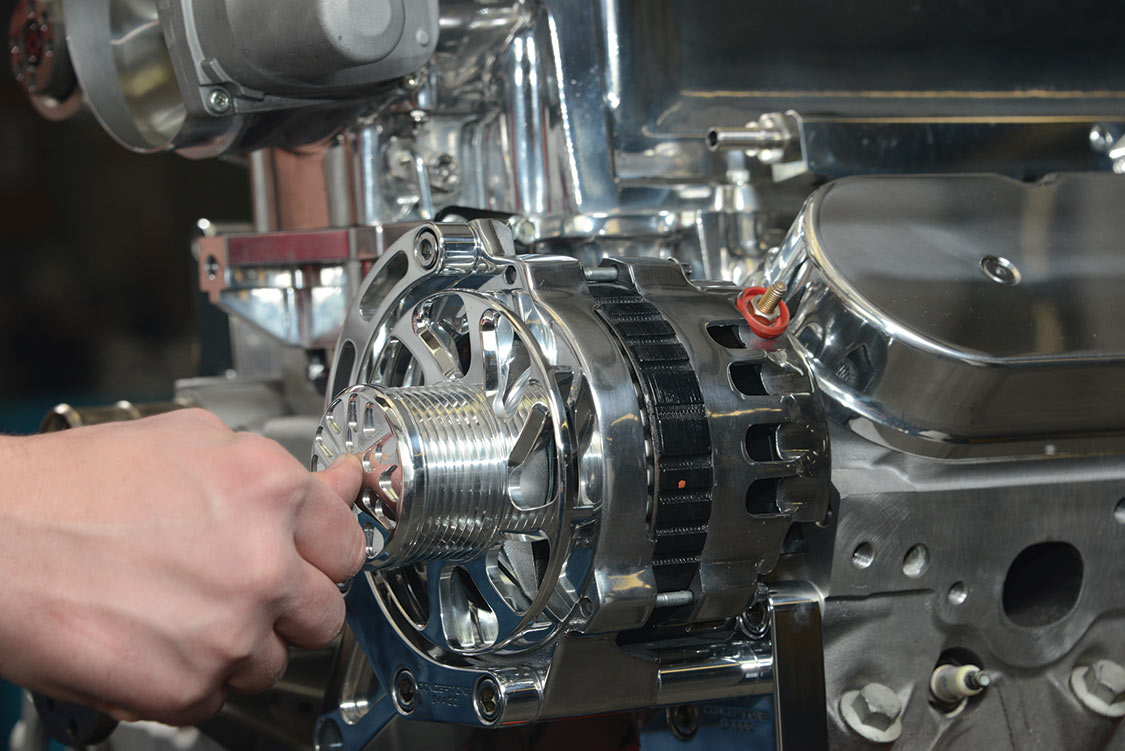

“You couldn’t buy a pulley system—just pulleys. You had to make a stock bracket fit, and you could buy a pulley here and a pulley there, or maybe a set of pulleys, but then you’d have to find a set of brackets that would work, or find the right water pump that lines up, or you’ve got to get this compressor or that,” Kevin says.

The solution was obvious. The Redd brothers needed to create a full set of components, pulleys and belts designed from scratch to fit each type of engine on the market. They called their company Concept One.

“We started off by making racing parts for another company, but we wanted to branch off and make our own products. We were the first to build complete kits. We figured out that we could build a complete system and furnish a water pump that we knew was going to bolt up, a power steering pump and all that stuff. It made sense and we had seen the need,” Kevin says.

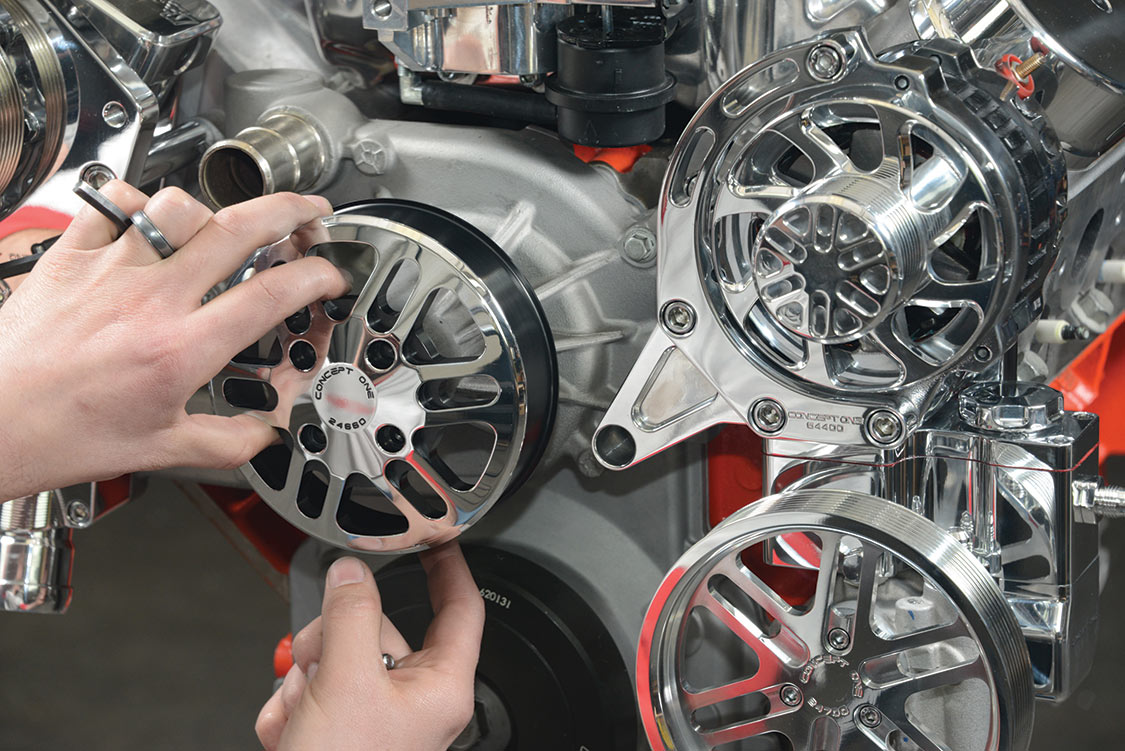

The difference between a Concept One kit and other pulley kits is that the Redds supply everything from the components to the pulleys, brackets, tensioners and belts needed for just about every popular GM or Ford engine type. The kits also include a custom power steering fluid reservoir.

“We buy the alternators, power steering pumps, water pumps and compressors from other companies, but we standardize all our stuff,” Kevin says.

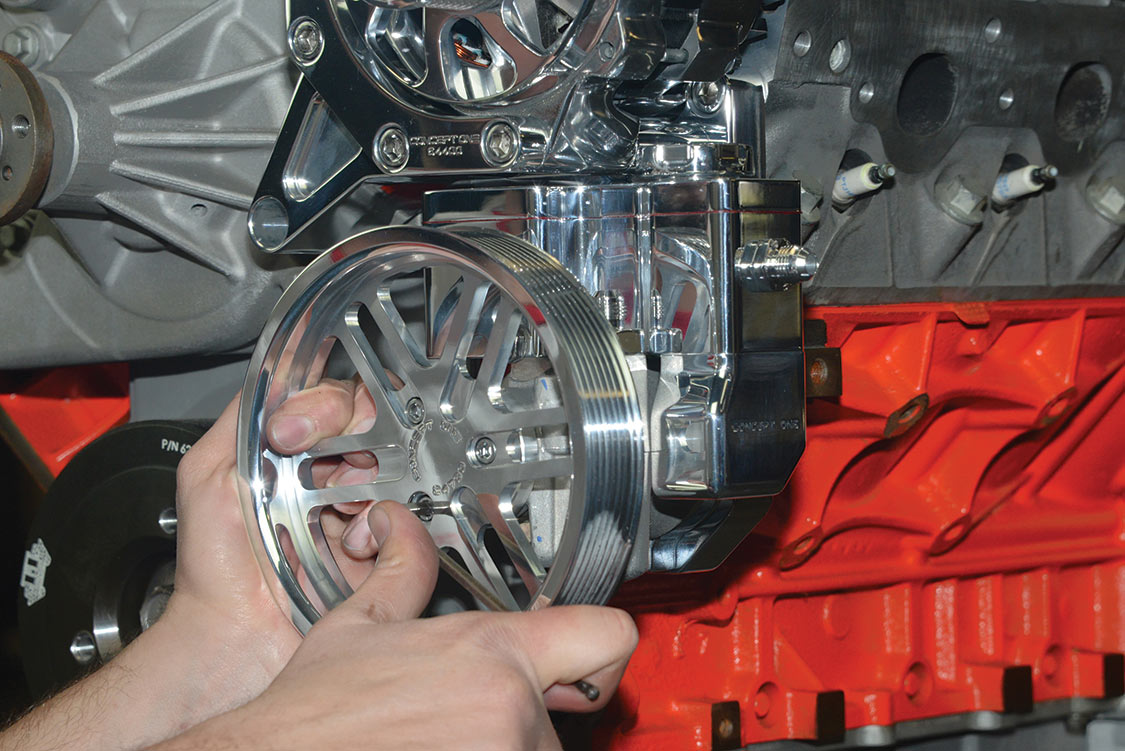

Each part is polished to a proper shine for a dressed-up engine bay. What’s more important, though, is that all the parts are made to go together on a specific engine block, so the installation process is quick and easy. Fit-up is always the challenge with aftermarket parts.

“We try to focus on our motto: Clean and Simple. We want someone to be able to buy this thing and be able to bolt it on without having to do any shaving, any grinding, or any of that type of thing. Our kits are made to fit,” Kevin says.

The result of the specialized design for each engine type, as opposed to a kit that tries to be one-size-fits-all, is that the parts are really designed to work together, rather than a patchwork of different items.

One of the benefits of going with a coordinated belt drive system is the modern serpentine belts are less likely to come apart or come off the pulleys than traditional V-belt designs. By matching the offsets of all components exactly and using the flat serpentine belt design, your engine’s reliability is increased along with its visual presentation.

The only part of a good system that comes off the shelf is the one you want to have readily available. Make sure that any system you buy from any manufacturer uses standard size belts, so you can easily find a replacement.

Tip: Never buy just one belt. Always keep a replacement handy, because the moment you need it may be the moment you’re not in a position to find one.

“You might not be able to find the Goodyear Gatorback, but you should be able to find a good belt in the right length. Most of our kits use a standard 6-rib belt, except for the supercharger kits. Those use 8-rib belts,” Kevin says.

The Concept One serpentine belt kits support the industry’s most common OEM and aftermarket superchargers used on Chevrolet LS series engines. When the kit is ordered, the buyer simply specifies the Magnuson, Edelbrock, Whipple or Chevrolet LSA supercharger, and the kit is made to fit the unit.

The brand of supercharger you choose is only part of the equation—you also need to decide what diameter of pulley you will use to get the boost pressure you want out of the blower. It’s even possible to get replacement pulleys with different diameters to achieve different levels of boost for street or racing use.

Top aftermarket superchargers can boost engine output well past 500 hpº in the LS series, and if you’re going there, you really need a drive system you can rely on. To keep the quality high, it’s important that all the brackets and pulleys be machined out of solid blocks of aluminum.

Cast pulleys have been known to break with disastrous consequences. Whatever belt drive system you choose, keep a critical eye on pulley and bracket quality.

As you imagine, research, design and implement your engine build, it’s good to give some thought to the necessary extras. With a planned belt system to drive your engine’s supporting components, you can dress up your engine, help ensure reliable performance, and make life easy on yourself as you build out your plan.

Mopar enthusiasts will note that the Concept One kits are limited to Ford and Chevrolet engines at this time.

“We keep kicking that around. We’ve been saying we were going to do it for a long time, but we haven’t done it yet. Right now, we’re trying to decide what we’re going to do next—is it late model Mopar or maybe the new LT1?” Kevin says.

As always, the best way to get the aftermarket to respond is to demonstrate demand. Our cover car this issue is a perfect example, and we hope to generate enough buzz to get a perfect pulley system for Mopars soon.—JZ

Share Link