MICHAEL ECKERSON

.

February 03, 2023

.

All Feature Vehicles

MICHAEL ECKERSON

.

February 03, 2023

.

All Feature Vehicles

I’m a fan and regular viewer of PowerNation’s popular Truck Tech. Truck Tech gives viewers insight and information from the mechanic’s perspective. Their knowledge definitely helps guys like me understand and appreciate all the work that goes into these kinds of projects. They spotlight everything from simple repairs and upgrades to full-blown rebuilds. I get inspired every time I tune in.

Recently I had the opportunity to chat with one of the hosts, Lawrence “LT” Tolman and find out a little more about him, the show, and some of their upcoming projects. LT and I met up at SEMA to catch up and talk about the future of Truck Tech. Here’s a little of our conversation.

D!: LT, thanks for taking time to share your story with our readers. Let’s start with a little history on you. How did you find yourself on Truck Tech? Have you always wanted to be a TV show host?

LT: Well first of all, I never imagined I would be a TV host, nor was it even on my radar of possibilities of a career path. I grew up with a keen interest in all things mechanical, I guess I just had a knack for it, and I knew I wanted to do something with my career automotive related, I just wasn’t sure what. I always have had car and truck projects I’ve been working on, and constantly pushed myself to learn more aspects of automotive customization and repair. I bought my first truck, a ’76 Chevy C/10 when I was 13 years old.

It needed some major body repair, as I lived in the north, and the truck had rusted out. I started by learning how to take fenders off, and doors apart, and how to weld in patch panels to repair rust, and eventually how to do body work, prime and paint.

Then, I moved onto the mechanical stuff, like rebuilding the suspension, swapping in a larger engine (a 472 Cadillac V8), changing the trans, and so forth. I went to college and got a degree in Business Management with a minor in Mechanical Engineering, but always had a passion for building cars.

I’ve been a long-time viewer of the entire PowerNation TV shows, and have been a loyal viewer for many years. In late 2014 they ran a commercial saying they were looking for a new host, and you were to make a video showing some of your work, and I thought “that would be an awesome job, but there’s no way I’d ever be chosen”, so I let the opportunity pass by. But, a couple months later, they ran the same commercial again, and my wife encouraged me to apply for it, because she knew I had what it took. So the short version is, we made a video, and they must’ve liked something about it, because here I am.

D!: What’s a typical day filming Truck Tech?

LT: There is a lot that goes into filming a TV show, and it varies day to day. Part of the time is spent writing scripts, ordering parts, and planning out the show, but most of the time is actually working on the projects while filming it.

Compared to what guys do at home or in their shops, filming a television show slows work down considerably, so a project that might take the average guy 2 hours, might take us 6, because were constantly changing shots, adjusting studio lights, cutting audio lines, etc…

D!: The show is very informative. Will you share the details of your most challenging project so we get a sense of the obstacles you and Jeremy face to bring the show to life?

LT: Probably the biggest challenge of making a “how-to” television show, is choosing what is important enough to make it in the show, and what we have to skip over. Our episodes are 30 minutes, which seems like a lot, but the time goes by quickly, and there is a lot of “tech” we have to skip in order to complete the project in the allotted TV time.

Also, we have to remember our audience is a mix of amateurs and professionals, and as seasoned builders we take the basics for granted, but we always try to remember to show our viewers a good mix of basic and hard-core tech.

D!: How do you and your team get ideas for your episodes?

LT: For the most part, it’s up to my co-host Jeremy Bumpus and I to pick what we think is “cool” and our viewers would enjoy. Usually, its something that he or I have always wanted to build. For example, project “SuperMax” is something that I’ve wanted to do for a very long time, and we had the perfect opportunity on the show to build it, so we did.

As long as its something our viewers would enjoy, and we have good “tech” to show along the way, it usually makes a good project. At the end of the day, our job is to teach and encourage our viewers, and to get them out there, and try what we’re doing for themselves.

D!: You guys showcase a lot of new products. We’re always interested in the next cool thing. What’s the next cool thing you have seen?

LT: I’m really impressed with advancements in the retrofit fuel injection market. Guys can take an old-school engine like a nailhead or flathead, and put electronic ignition and “self learning” fuel injection, which will increase power, and make an old engine more usable, and not require a degree in computer science. I am also impressed with advancements in CAN bus electronic solutions, making it possible to swap engines in new cars, and maintain OE levels of functionality.

D!: You are a big fan of the diesel platform. What are your favorite things about the diesel engine?

LT: The stereotype many people think of when you say diesel is a big pickup or semi, or piece of industrial equipment that’s used for hauling, construction, farming, etc. Outside of the stereotypical “truck guy,” most folks don’t think about using a diesel powered vehicle as a daily driver, mostly because their haven’t been that many domestically available options, and a ¾ ton pickup isn’t always the best choice for people living in the city or commuting.

So I am excited to see more diesel engine options in ½ ton trucks like the Ram EcoDiesel, and Chevy just announced a diesel for their Silverado 1500. There’s the Colorado with the 2.8 diesel, plus, for car folks, there are more options like the Chevy Cruze, plus BMW, Porsche, Audi, and VW all offer diesel powered cars/SUV’s.

There are two things I love about diesel engines: its fuel efficiency and power potential. Compared to gasoline engines, diesels generally uses much less fuel to do the same amount of work, given an apples-to-apples comparison. Remember the TDI Jetta’s that would get 50-some MPG?

Aside from the stigmatic “diesel-gate” scandal, VW’s diesel compact car is a win-win, especially considering its gasoline powered counterpart would top out in the mid 30mpg range.

Secondly, my specialty is high-performance, and diesel engines can see tremendous power gains with simple changes to tuning, while still getting great fuel efficiency. For example, any of the big three’s HD trucks can be tuned to easily make 100hp over stock (and usually 200lb.ft. of torque) without changing any hard parts, plus, still remaining 100% emissions compliant.

And once you start changing things like intake and exhaust, those gains can go much higher. Comparatively, in a gasoline engine, if you see 40hp from a tune only, that’s a good day.

D!: What do you think the future of “old-school” hot rods will look like now that consumers have more hybrid, electric and possibly hydrogen fuel options?

LT: I don’t think the traditional hot rod or muscle will ever go away, it’s just too big a part of American car culture. There will always be gasoline powered V8 cars tearing up the back roads and sitting at car shows on Sunday mornings. Detroit continues to pump out red blooded American muscle cars like the Hellcat, CTS-V, ZR1, and GT350/500 Mustangs.

And these days 700hp off the show-room floor is commonplace. Plus, even the sport compact segment is growing at rapid rates, with new entries like the Focus RS and Civic Type R. And while many don’t consider those to be “hot rods”, to the younger generation, these are the modern muscle cars.

But what I’m excited to about is watching the “high-tech” hot rod market evolve. Exotics and “hyper cars” have been offering hybrid performance cars for some time now, which use a combination of electric and gasoline power to produce phenomenal performance figures, so its only a matter of time before someone starts to adapt that technology into an older vehicle.

And just like you can swap a gas engine for a larger more powerful one, I can’t wait to see someone take a car like the Tesla (which already has incredible performance) and swap in a much more powerful (or additional) electric motor. Hot rodding will never die, the methods just will just to adapt and evolve.

D!: You’re a family man and father. What do you daily-drive?

LT: Well I’ve always been a truck guy. And though I’ve owned a couple muscle cars here-and-there, it seems like I drive trucks more than anything, and just about every one of ‘em has been a Chevy. Right now, I drive a LMM Duramax-powered ‘08 Silverado 2500HD crew cab. For my needs, it’s a do-all, best of all worlds vehicle.

There’s a ton of room in the back for booster seats, it’s roomy and comfortable on longer trips, it’s efficient for its size, and I can haul or tow anything I want. But most importantly for me, is the performance potential.

Right now, it is pretty close to stock, but doubling the power of a Duramax is super easy. So, I hope one day to build the bottom end, upgrade the fuel system, add compound turbos, and have an 8-900hp daily-driven diesel pickup, that can still be efficient, reliable, and haul a trailer.

D!: What’s your dream car?

LT: Easy. It’s a Koenigsegg One:1, a Swedish Megacar that achieves the “golden ratio” of one horsepower per kilogram of weight.

However: While exotic cars are cool and all, Ill probably never own one, and if I did, I’d probably be too afraid to drive it, for fear of someone parking too close, rock chips, speed bumps, other motorists, etc… For me, a dream car is one you make your own. I’d rather take simpler car, upgrade the power, looks, handling, interior, and be able to enjoy it every day. And don’t forget, a car you customize to your tastes will also be a one-of-one.

D!: What’s the worst car you ever owned and why?

LT: I’ve had pretty good luck with cars, mostly because I can spot potential problems before buying, and I can make any repairs needed. So, I guess I’ve never had a bad “lemon” type car. But the worst, rather, most embarrassing car I’ve owned, would be a mid-90s Pontiac Bonneville I bought in college for $300. I drove it for a few months, fixed a few problems, and soon traded it for (you guessed it) a Chevy Truck.

D!: Any advice for our readers that are considering careers in automotive repair and restoration?

LT: You’ve heard the saying “do what you love, and you won’t work a day in your life”. So, I say, If you enjoy working with your hands, do it! The country is in need of skilled technicians in the automotive industry, and really, in all skilled trades. While many kids are taking the traditional career path, there is nothing wrong with learning a skilled trade, and going to work. In some cases, its easier and quicker to find a job, and sometimes starting salaries in the trades can pay more than traditional 4 year college degree jobs.

D!: What do you and Jeremy have in store for your viewers this season?

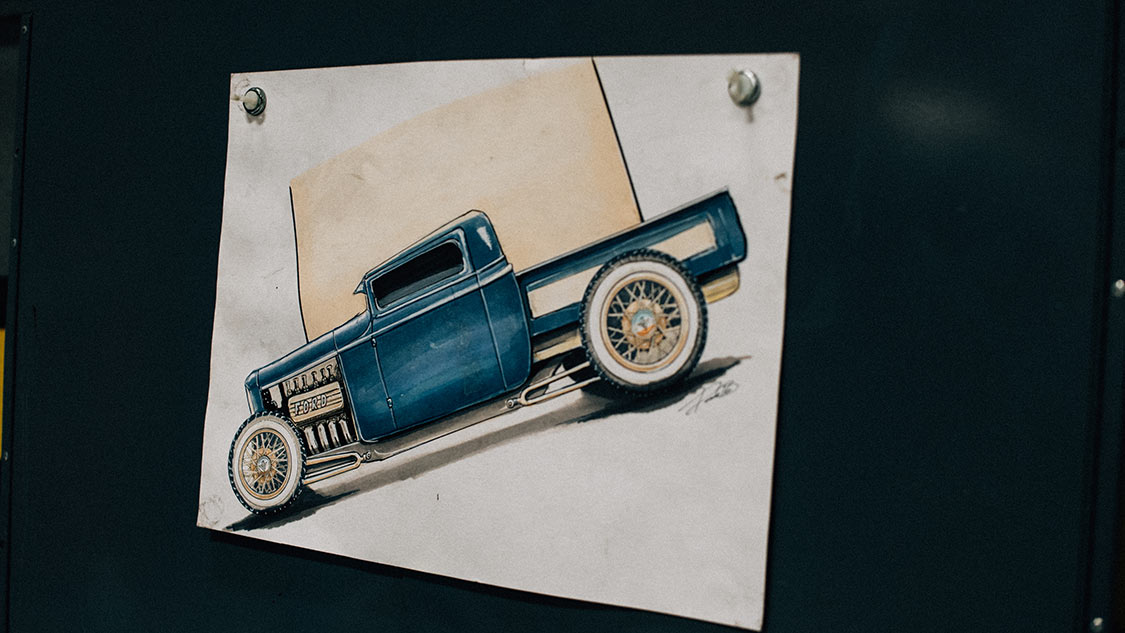

LT: Right now, we have a cool range of project vehicles were building, in several styles, ranging from a 1930 Ford Model A traditional street rod, a late 80s K5 blazer in a show-truck flavor, a ’74 F-100 corner carver, and we also have some new exciting projects we can’t yet talk about, but stay tuned!

D!: For sure. Thanks, LT.

Be sure to check out Truck Tech and the whole PowerNation family of shows Sunday mornings on the Paramount Network, and powernationtv.com

Editor’s Note: A version of this article first appeared in the April 2018 print issue of the Drive Magazine.

Share Link