Jerome Andre

.

August 02, 2023

.

All EV Vehicles

Jerome Andre

.

August 02, 2023

.

All EV Vehicles

Meet Jack Kerridge, the automotive talent behind the wheel at Silent Classics based in the southwest of the UK. With classic cars coursing through his veins from an early age, Jack’s destiny was sealed as he tinkered away in his father’s workshop, immersing himself in the art of car restoration. Here, he cultivated the skills and meticulous attention to detail that set him apart.

Motivated by his love for his struggling Fiat 126, Jack reached a tipping point when its underwhelming 0.6-liter engine repeatedly succumbed to failure. Driven by determination and a stroke of inspiration, he took matters into his own hands and embarked on a transformative endeavor—his inaugural electric conversion—revitalizing his cherished vehicle.

The resounding success of this project ignited a newfound passion within Jack, propelling him to push boundaries even further. Fueled by a fervent desire to merge cutting-edge battery technology with his deep affinity for classic cars, he gave life to the visionary concept that would later become Silent Classics. Determined to specialize in a particular vehicle, he recognized the Fiat 500 as the ideal candidate. Despite its elegant and beautiful design, the car was let down by its conventional powerplant.

Converting and restoring a Fiat 500 requires immense patience above all else. The team at Silent Classics has developed exceptional proficiency in the restoration and conversion of these vehicles thanks to their profound understanding of the original design and electric vehicle technology. What truly sets them apart is the remarkable diversity within their team, encompassing backgrounds in restoration, electronics, and 3D design.

However, like any intricate undertaking, the team encountered several problems throughout the project. One major challenge involved accommodating an adequate battery pack capacity within the small car without compromising its performance or safety. Achieving the right balance between power and efficiency required significant trial and error. Over the course of the past two years, the design of the car has undergone substantial evolution, incorporating numerous small design changes to refine the conversion kit and ensure optimal performance.

To solve the problems, the team engaged in extensive experimentation and research. They sought guidance from experts in the field, conducted tests with various components and configurations, and embraced the valuable lessons learned from their mistakes.

One key solution involved utilizing the most energy-dense modules available. By acquiring and implementing Tesla Model S modules, offering superior energy density compared to LifeP04 prismatic modules used in previous builds, the team successfully achieved their target of a 100-mile range. The Tesla modules offered improved energy density and occupied less overall space within the vehicle, contributing to a more efficient and effective conversion. Their only drawback is their length, but the team squeezes them under the hood and in the trunk.

With these electric marvels, charging at any public Type 1 or 2 AC charging station is a breeze. When you’re back at home, a simple socket is all you need for a top-up. From 0 to 100%, expect a charge time of just over six hours, ensuring you spend more time on the road and less time waiting.

Featuring a potent 44kW-160Nm electric motor and a single-speed drivetrain, our test car performs superbly while oozing simplicity. In many ways, this takes driving to new heights.

All that hard work paid off. The drive is superb and better than I imagined.

Thanks to the instant torque delivered by the electric motor, keeping up with modern traffic is a breeze. With time, the team did adopt a mindset of working smarter, not harder. One example of this was designing the components to be mounted using the original fixing points. For instance, the electric motor was designed to bolt directly onto the rear panel like the original engine. This approach significantly streamlined the installation of the conversion kit, saving them a considerable amount of time. By leveraging the car’s existing infrastructure, the team optimized the conversion process and made it more efficient. In the operation of the EV build, the easiest part was undoubtedly the test driving, validating all the hard work put into the project. The driving experience exceeded expectations, delivering a superb performance.

As for us driving the 500E for the first time, I can confirm it is one of the best retrofit solutions out there and one of the lightest, offering unparalleled performance and comfort. The vast (by today’s standards) steering wheel that rubs on your lap makes directing the 500E quite an experience, but it is appreciable because it is so light, and the 500, now supercharged, becomes so nimble upon slightly pressing the Go pedal. All in all, this was a fantastic experience. Jack has since extended his offering to other brands and models, but he keeps an eye out for anything Fiat 500, including several variants.

If you’re considering building a similar Fiat 500 or any retrofit, here are some valuable pieces of advice:

1. Conduct thorough research: Invest time in understanding the intricacies of electric vehicle conversion. By comprehensively understanding the process, you can make informed decisions and avoid unnecessary back-and-forth during the design phase.

2. Plan the design from the beginning: Create a roadmap for your project, outlining the entire design and conversion process. This will help you stay organized and focused, minimizing delays and revisions. And accept the fact it will take twice the time you think it will!

3 .Choose components wisely: The components will shape the overall performance and efficiency of your system. Take the time to evaluate different options, considering energy density, compatibility, and reliability. Stay updated on advancements in EV technology, as compact and efficient components are constantly emerging.

4. Learn about EV’s latest technology: Keep well-informed about the rapidly growing EV industry. Stay updated on the latest developments, trends, and innovations in electric vehicle technology. This knowledge will empower you to make informed decisions and adapt to the evolving landscape.

By following these suggestions, you can embark on your EV conversion project with a solid foundation of knowledge and a supportive network, increasing your chances of a successful and rewarding experience.

OWNER: Jack Kerridge

MOTOR & DRIVETRAIN

BATTERY SYSTEM & CHARGER

CHASSIS/SUSPENSION

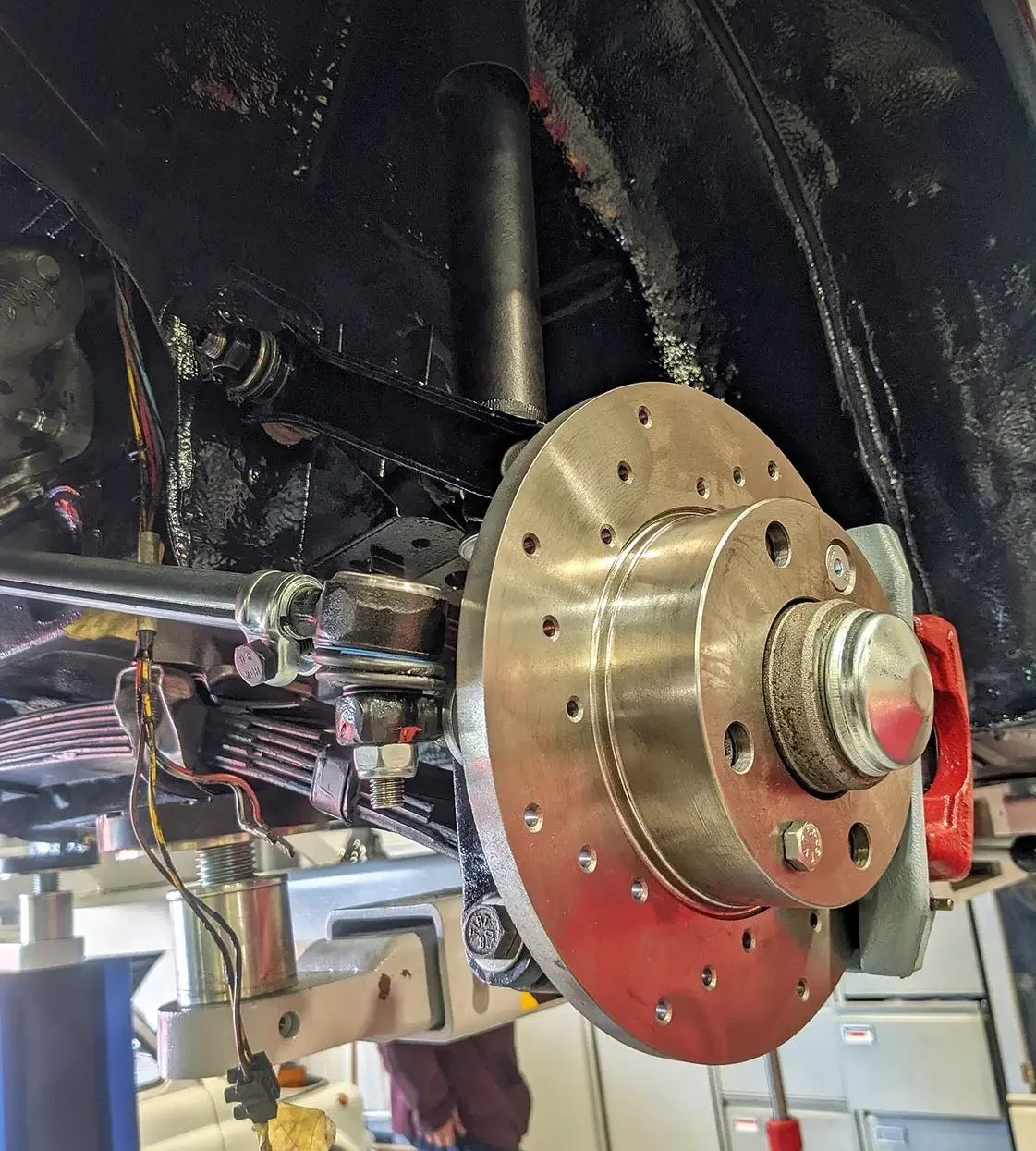

WHEELS, TIRES & BRAKES

INTERIOR

CONTACT

Share Link