Mike McGlothlin

.

September 12, 2023

.

Diesel World

Mike McGlothlin

.

September 12, 2023

.

Diesel World

For more than a decade, dealerships, independent shops, and private truck owners have been dealing with CP4.2 failures. The twin-piston, high-pressure fuel pump employed on the ’11-present 6.7L Power Stroke (as well as the ’11-’16 LML Duramax) has a long history of self-destructing and wrecking the entire fuel system when it lets go. In an instant, the CP4.2, high-pressure lines, fuel rails, and injectors can all become scrap, with a tank cleaning, potential lift pump replacement, and roughly 30 hours of labor all being part of what can easily amount to a $10,000 repair bill. Aftermarket disaster prevention kits and CP3 conversions have become common work-arounds, but only recently has anyone attempted to correct the inherent flaws in the CP4.2’s factory design.

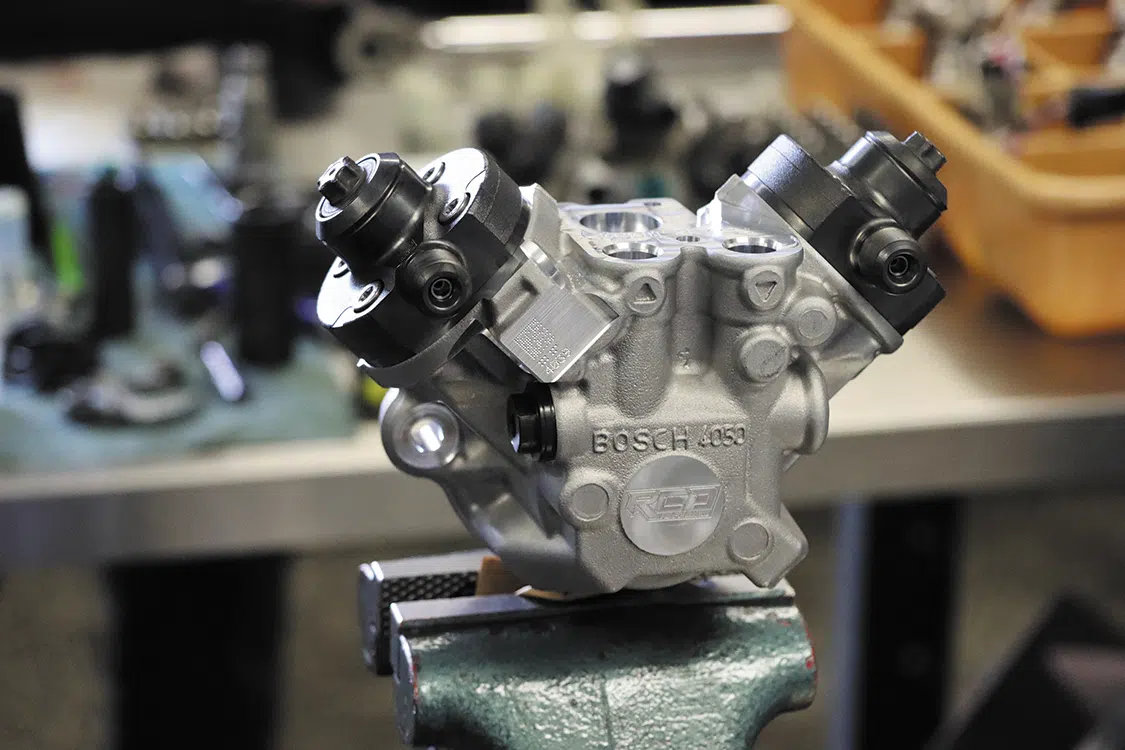

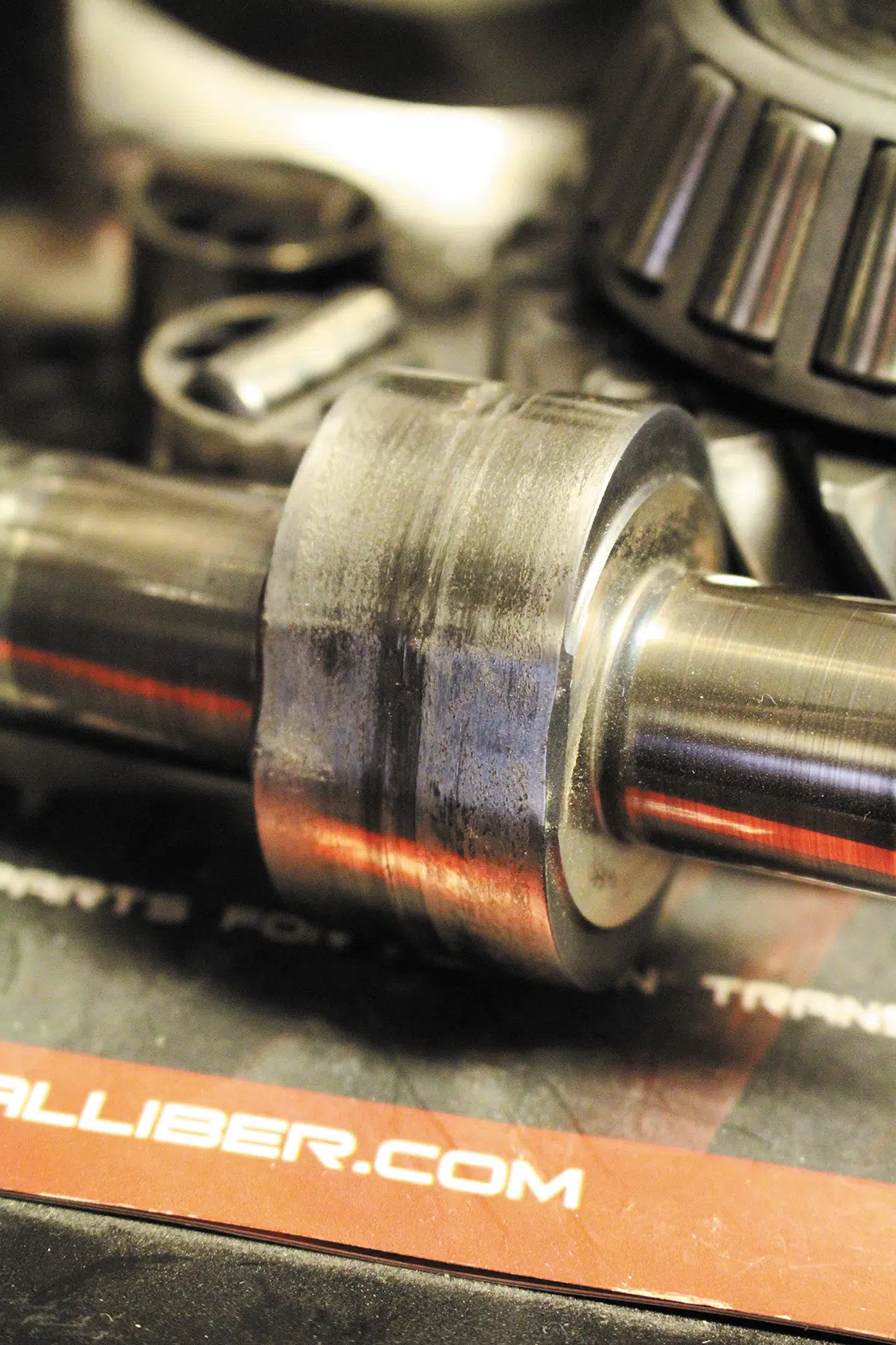

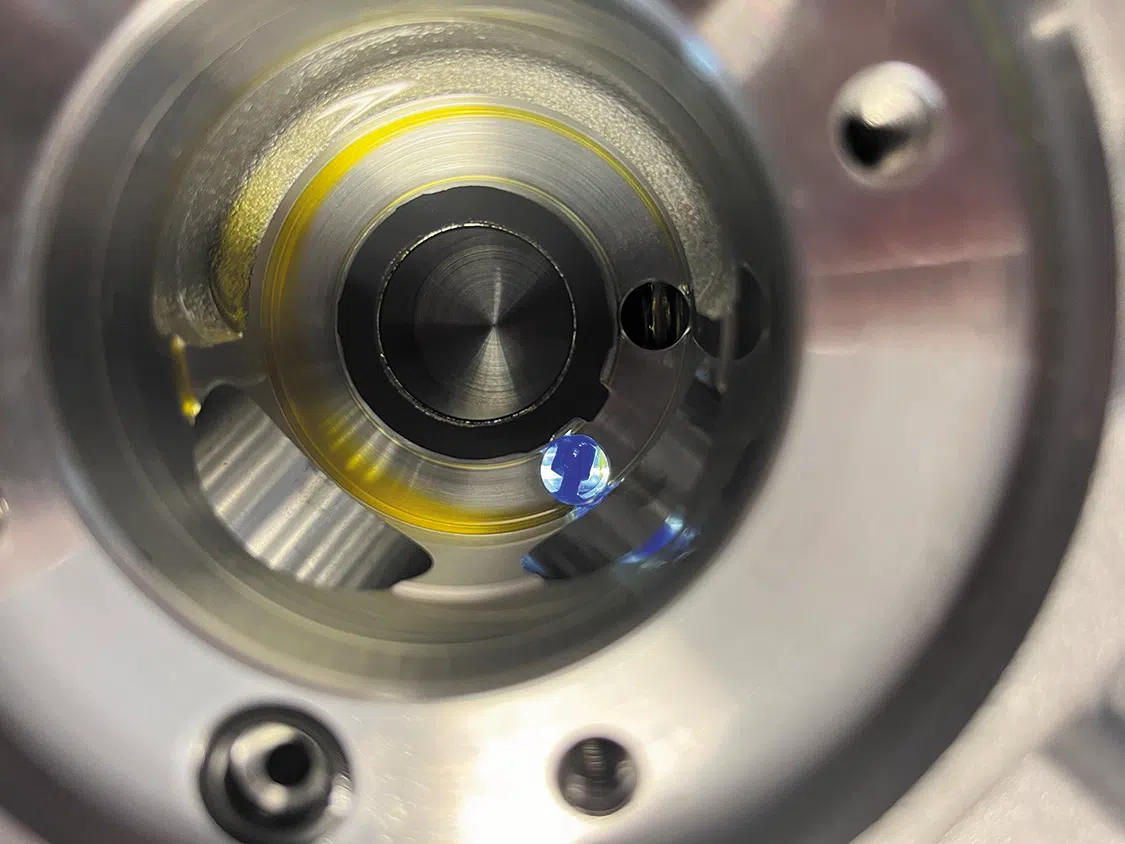

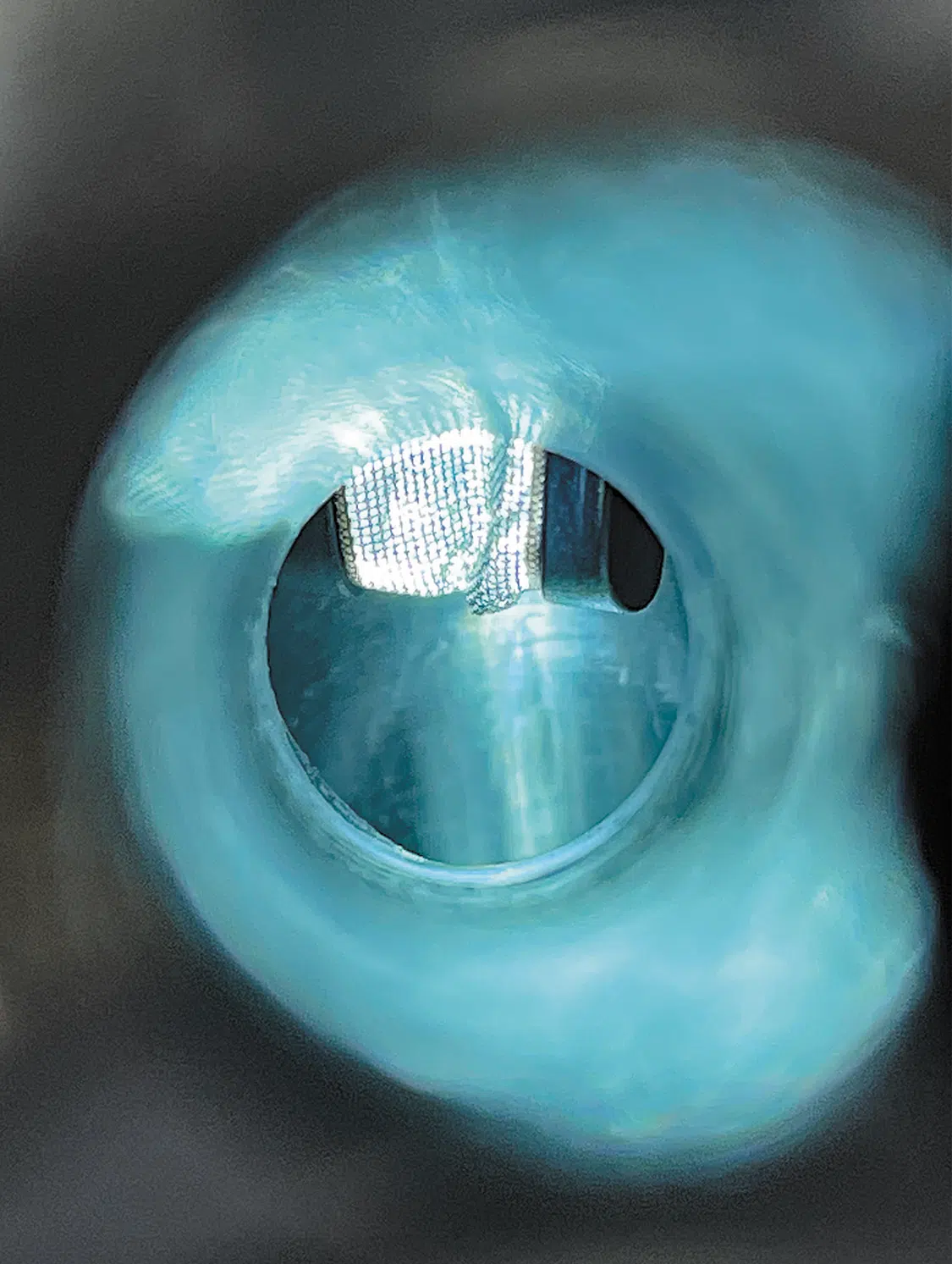

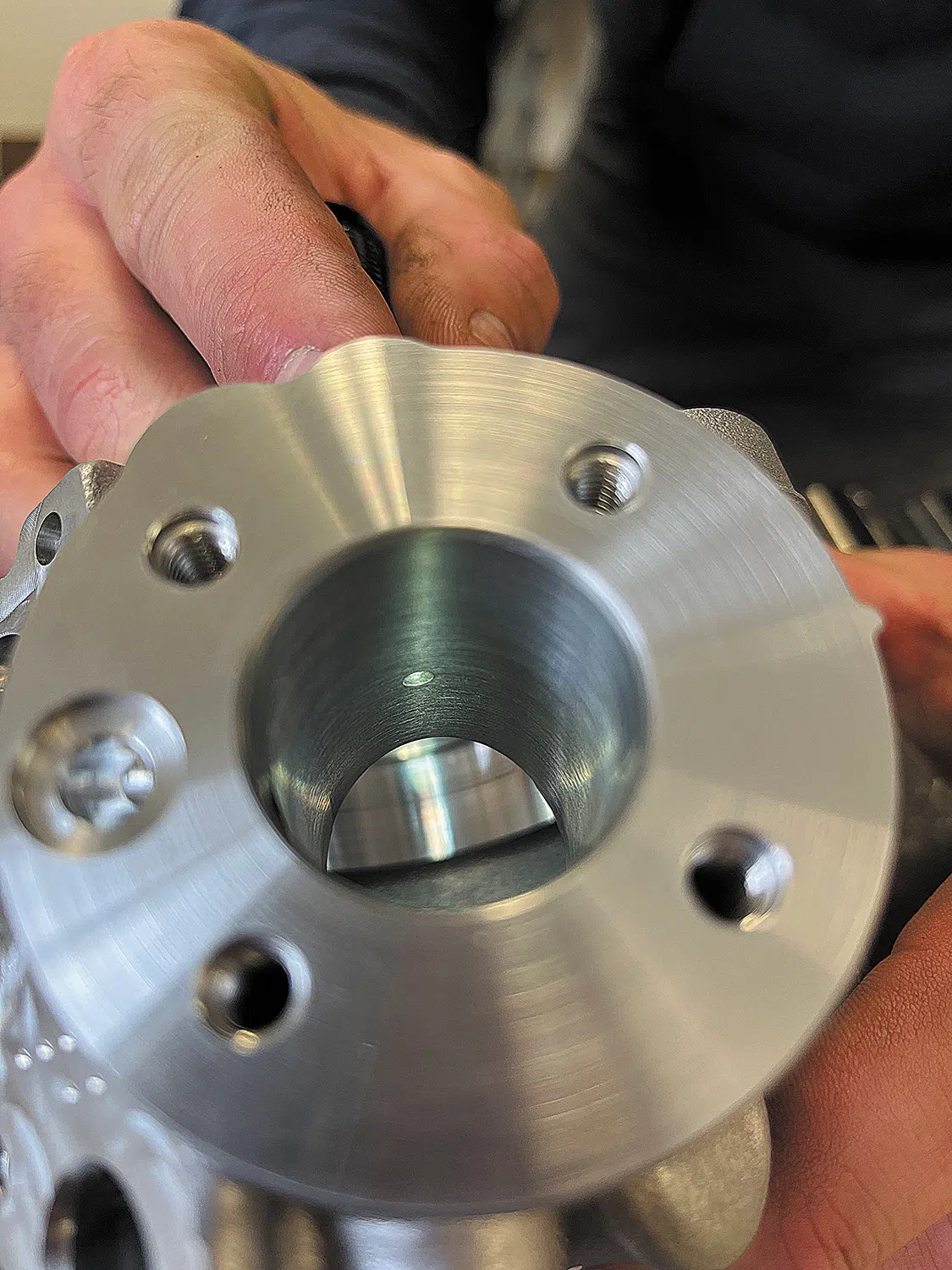

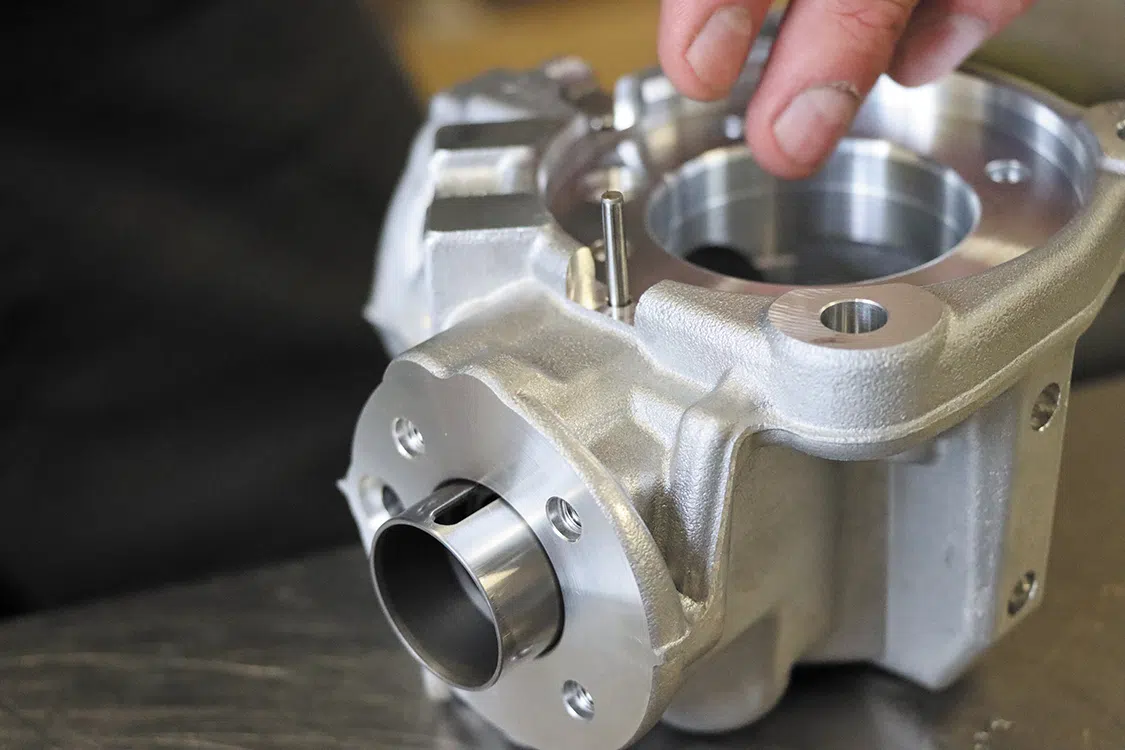

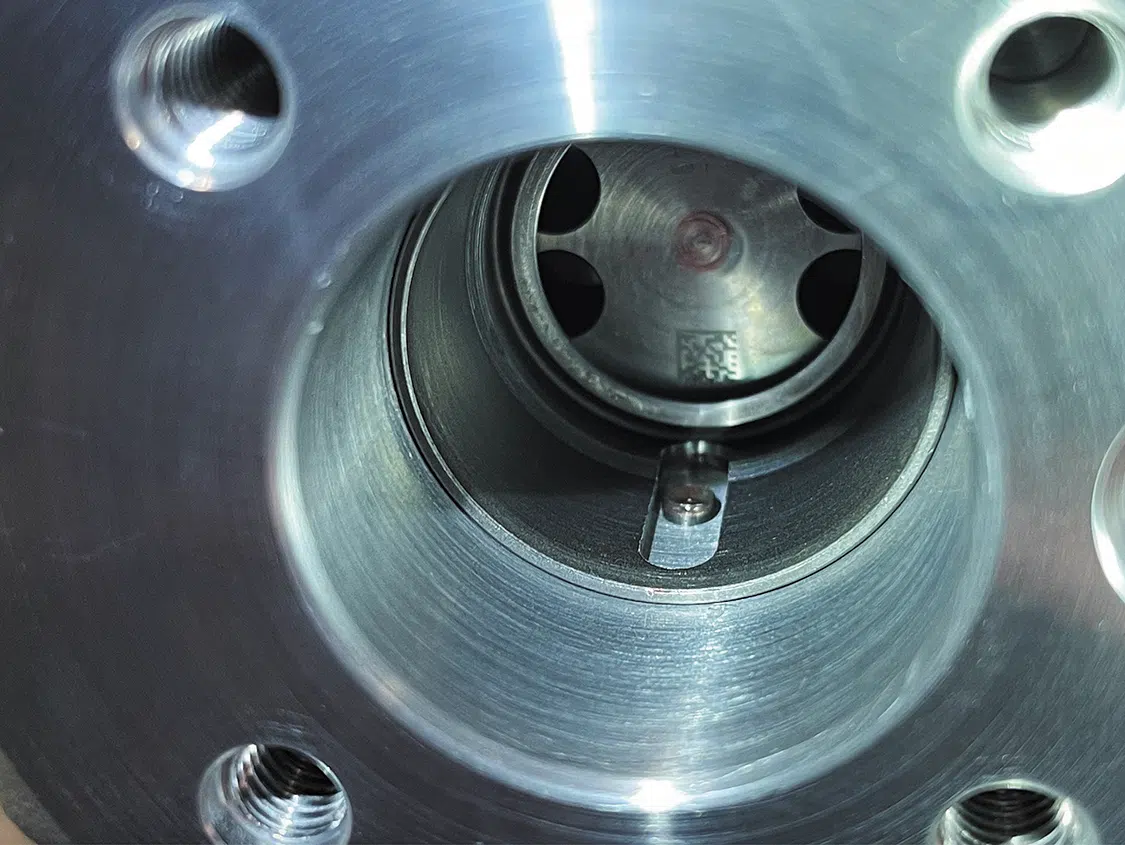

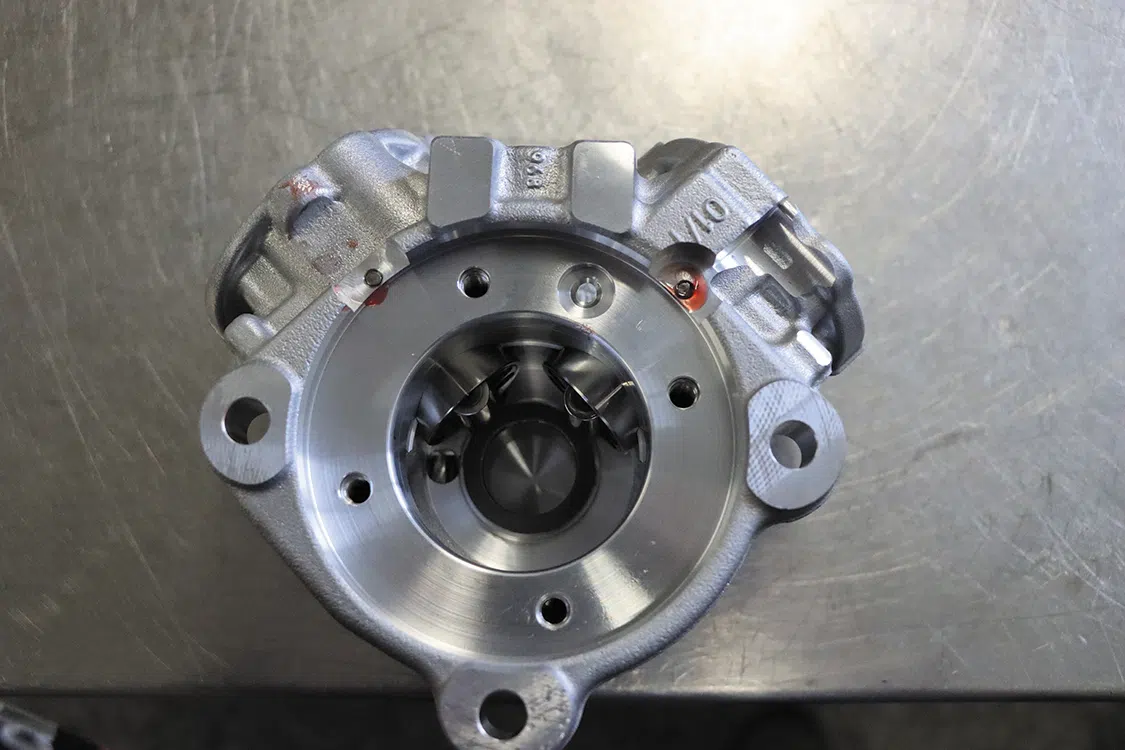

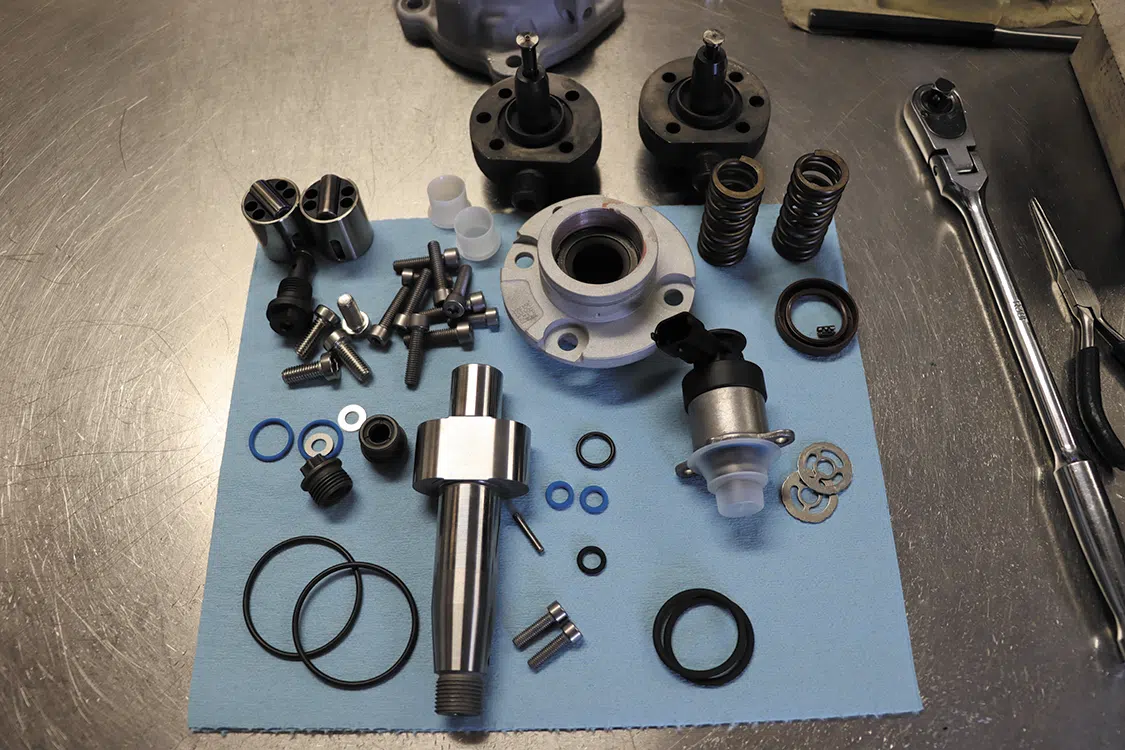

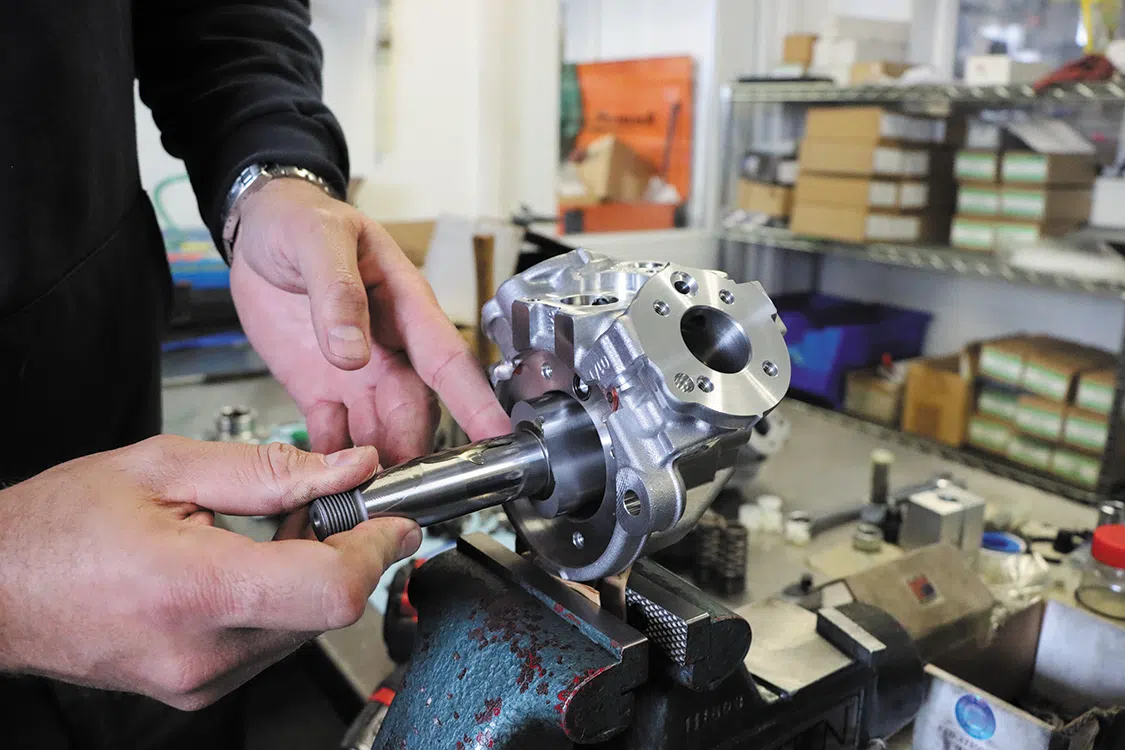

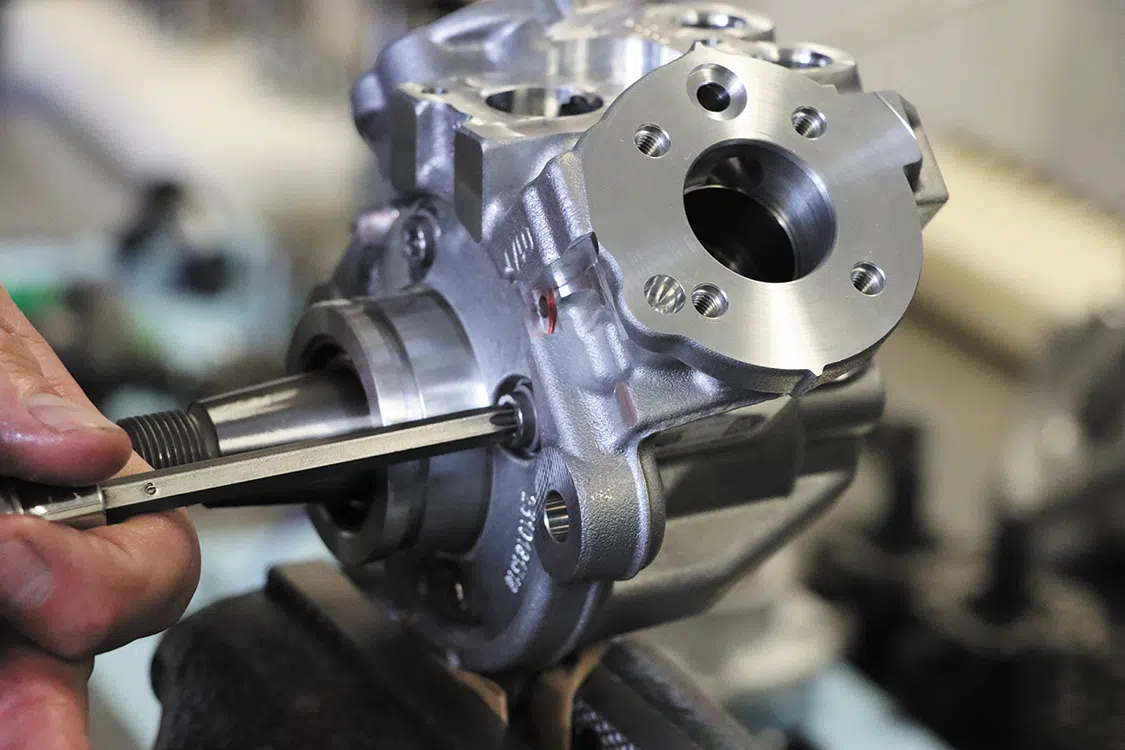

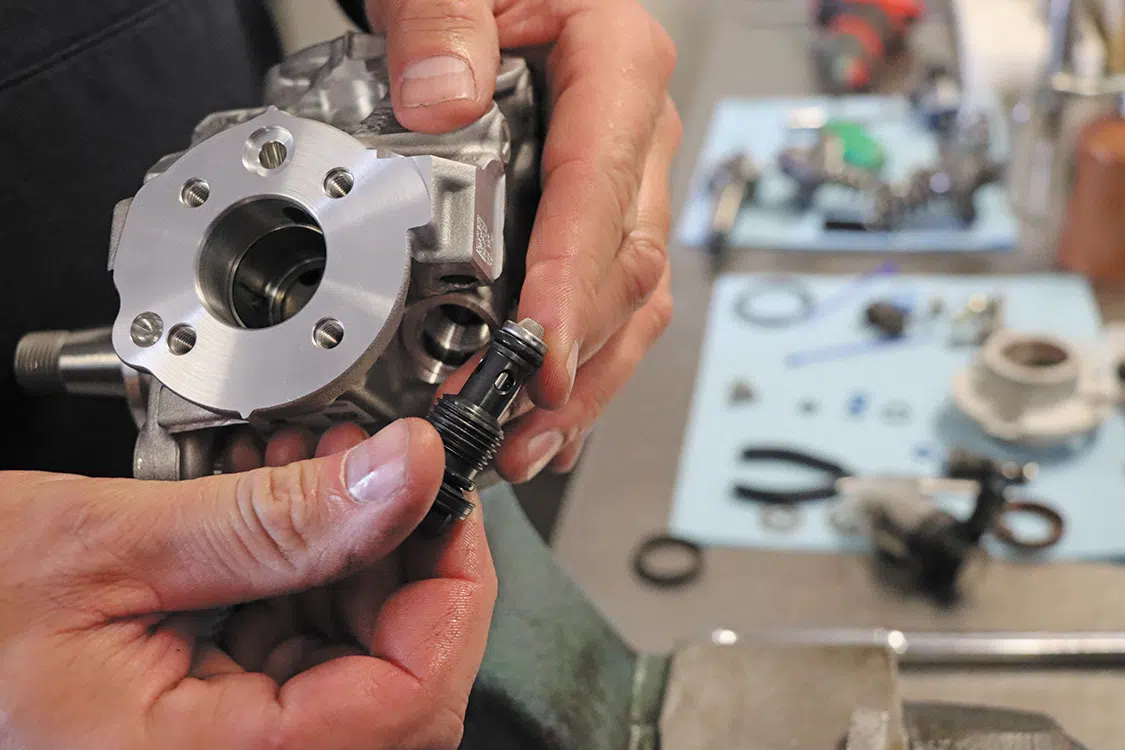

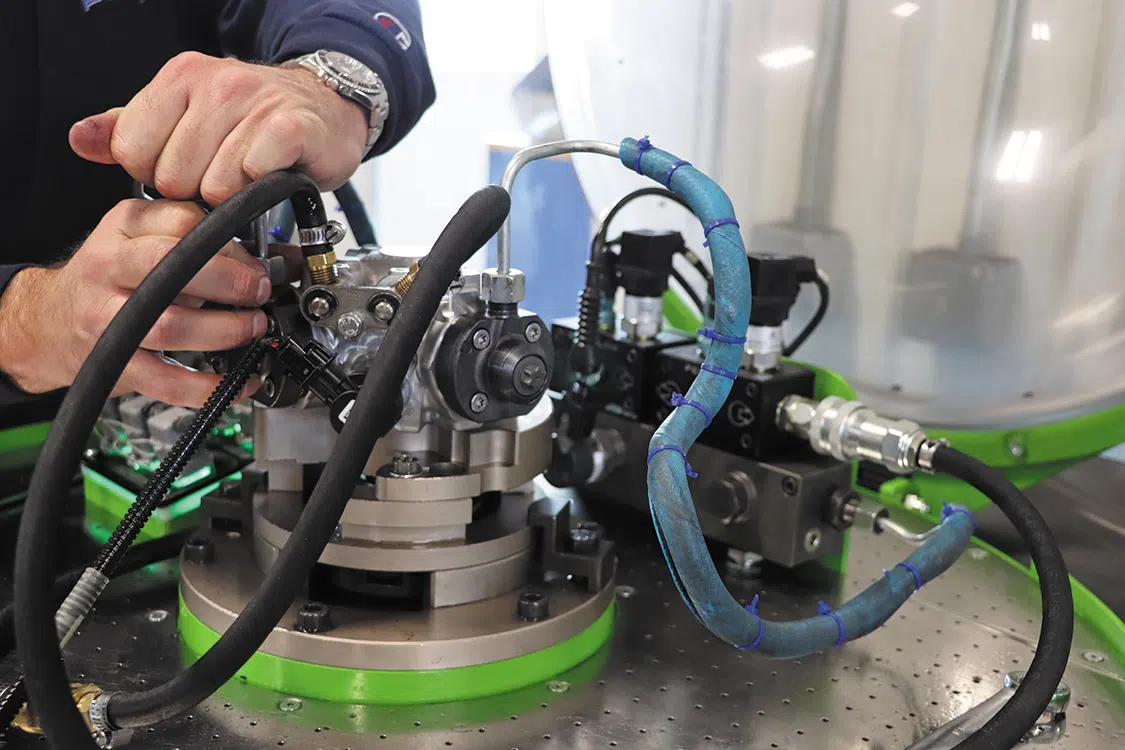

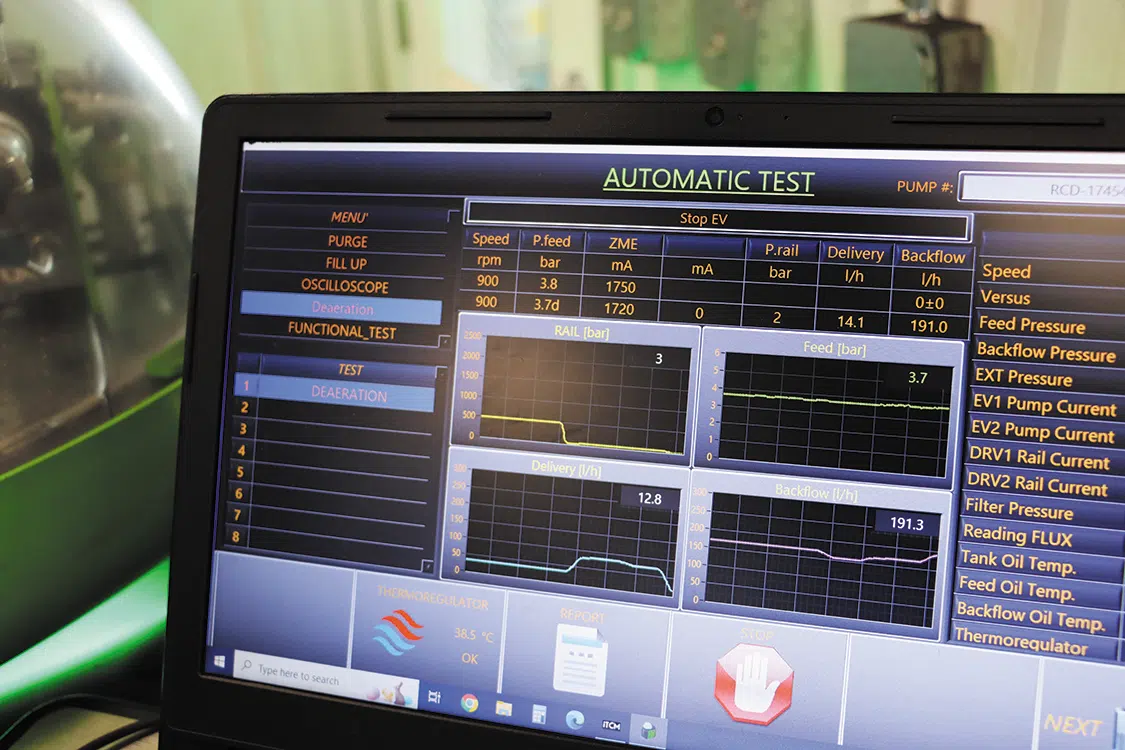

Meet the CP4.2 Bosch should’ve built: the CPX from RCD Performance. Its lifter buckets are pinned to keep them from rotating—turned lifter buckets being the primary failure that leads to metal-on-metal contact between the roller and cam. But on top of that, a revised feed port prevents any contaminated crankcase fuel from entering the plungers and barrels in the unlikely event the pump does fail. And it gets even better. RCD Performance offers three versions of its CPX for the 6.7L Power Stroke: a stock replacement pump, which features the same displacement the ’15-’19 CP4.2 did, a 10-percent over pump for aggressively tuned trucks, and a 10.3mm stroker pump that displaces 38-percent more fuel than stock. Join us for a look at the work the company performs inside its bulletproofed CP4.2 pumps.

RCD Performance

rcdperf.com

309.822.0600

We use cookies to enhance your browsing experience, serve personalized ads or content, and analyze our traffic. By clicking "Accept All", you consent to our use of cookies. Visit our Cookie Policy for more info.

Notifications

Share Link