Titus Bloom

.

October 16, 2022

.

All Feature Vehicles

Titus Bloom

.

October 16, 2022

.

All Feature Vehicles

In its 11th year, Gary Winter’s ’03 Mustang Mach I received a clutch upgrade. Nothing very remarkable there, you might think, as engine power increases so, too, must clutch holding power. Nor is the job arduous; that is if you have access to a lift and a transmission jack. At MV Performance the able Jason Carr completed the upgrade in around two and a half hours.

The car’s background is also worth exploring. In 2003, Winter unexpectedly needed transportation and set off to buy a pickup truck. He promptly selected the one he wanted, but came home with a new, red 4.6L Mach I Mustang instead. On his way to the sales office he caught a glimpse of the DOHC four-valve machine and changed his mind.

Since then the car has accrued 76,000 miles, and though it’s no longer a daily driver, it’s still active on the roads each month, making its way to car shows or to test and tune meets at local drag strips. Externally the Mach I’s appearance remains unchanged, except for the Billet Specialty wheels.

In the engine bay there resides a Ford Boss 5.0L block bored and stroked, which increased the displacement from 4.6 (281 ci) to 5.3L (324 ci). Built by MV Performance of Winder, Georgia, power increased from the stock 305 hp at the flywheel to 430 hp. The induction was changed to include a Sullivan intake and the factory computer was swapped for a Big Stuff3, which increased the engine’s rev range from 7,000 to 9,000 rpm and picked up a further 75 hp.

At the rear, stock springs were used but lowered by the removal of one coil. Also visible are Metco upper and lower control arms with Delrin bushings; earlier polyurethane bushings shattered. The axles are manufactured by Moser, and the shocks by Strange Engineering, who also provided the spool-style rearend.

For nimble quarter-mile performance, the stock transmission was incapable of fast shifting and was subsequently replaced by a TKO 500, which attaches to a Quick Time bell housing. Importantly, the transmission was sent to Liberty’s for face-plating, a process that results in rapid no-lift shifts during hard acceleration.

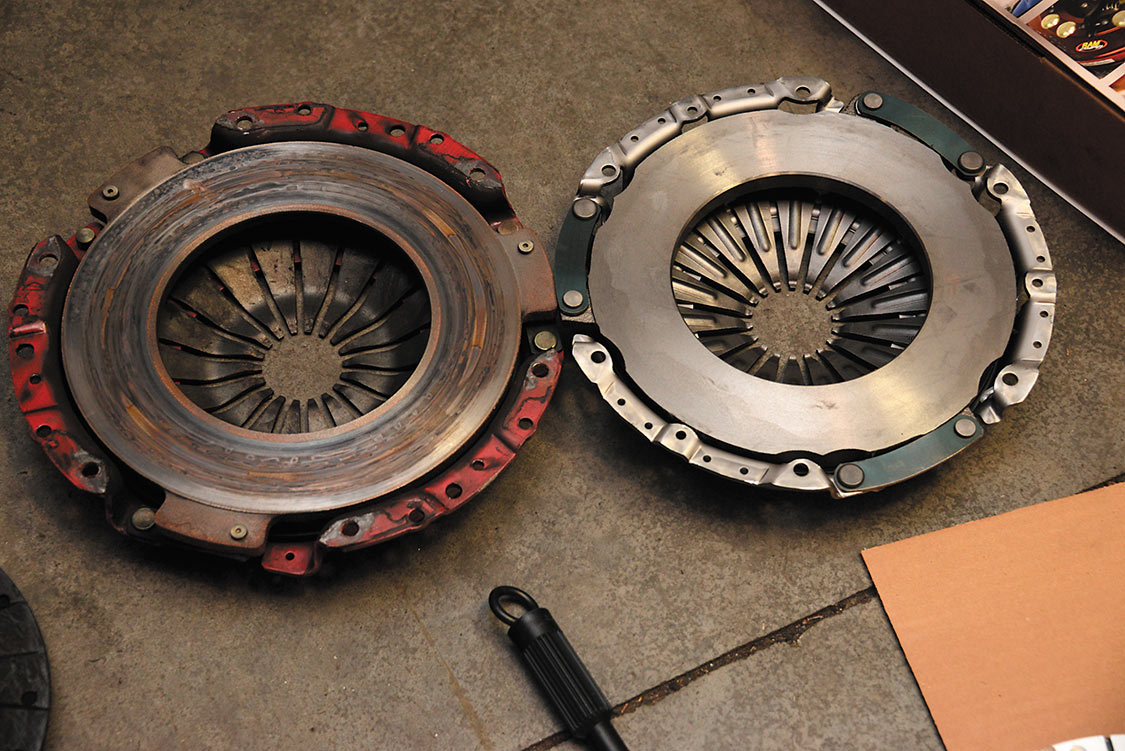

“I was cutting the lights at 7,800 rpm,” said Winter, “so we altered the rear gear ratio from 4.56 to 4.88:1. With the lower gear we’re aiming to exit the quarter-mile at 8,300 or 8,400 rpm.” During the latest upgrades, the Mach I received a Ram billet aluminum flywheel and Powergrip clutch assembly. A single-disc direct-fit arrangement, the 10.5-inch flywheel is lighter than the original by around 14 pounds. Lower mass means a lower moment of inertia, which translates to faster response, which means faster acceleration and deceleration as well as less wheel-spin. The increased clamping pressure of the new flywheel-clutch system accommodates power increases up to 550 hp while maintaining light pedal operation.

Ram Clutches

803.788.6034

Ramclutches.com

MV Performance

Winder, Georgia

770.725.7862

Mvperformance.com

Share Link