Dan Burrill

.

October 26, 2022

.

All Feature Vehicles

Dan Burrill

.

October 26, 2022

.

All Feature Vehicles

Three years ago, Scott Merrell of Classic Connection along with two other like-minded individuals bought two Ford GT40 Mark 4 chassis and bodies from Fran Hall at Race Car Replicas (RCR). Then, instead of the traditional 427 FE engine/transaxle combination, they decided to power these cars with the new Ford Coyote crate engine.

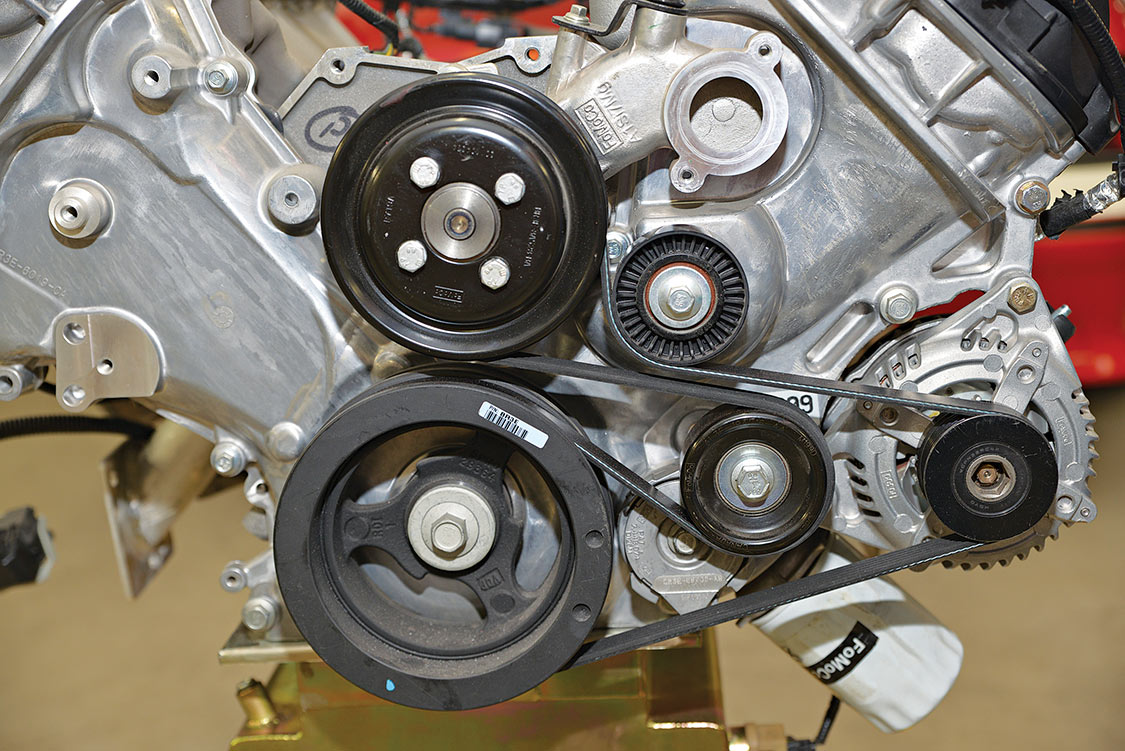

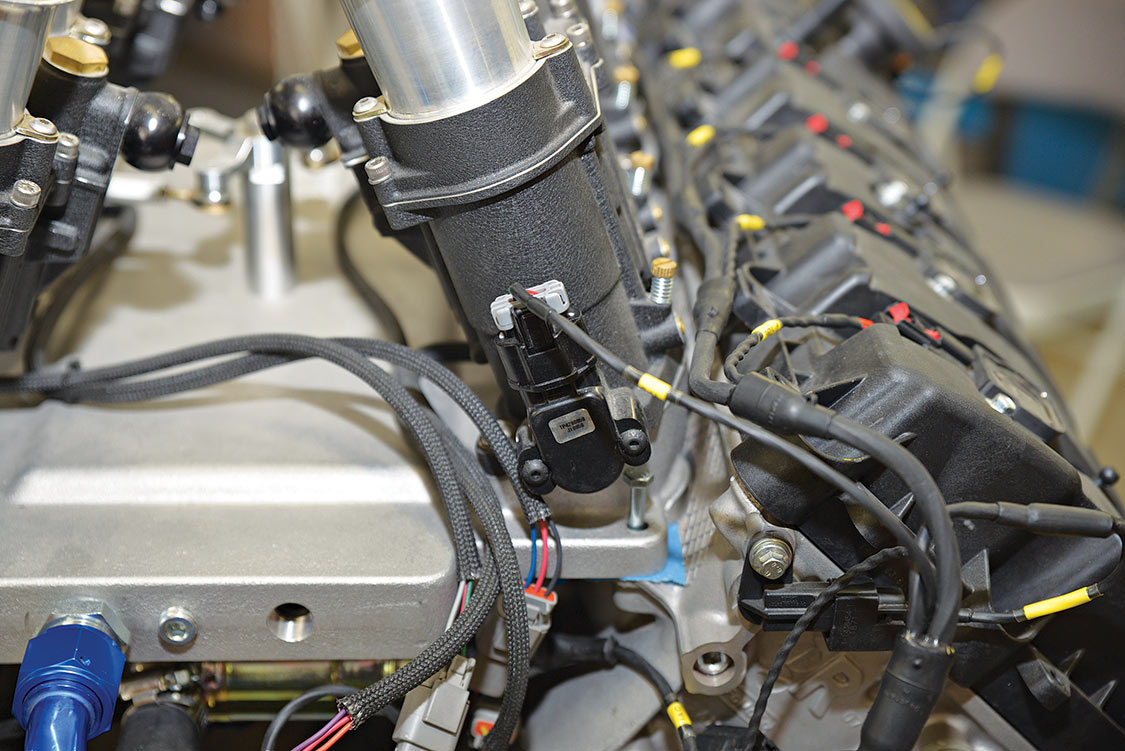

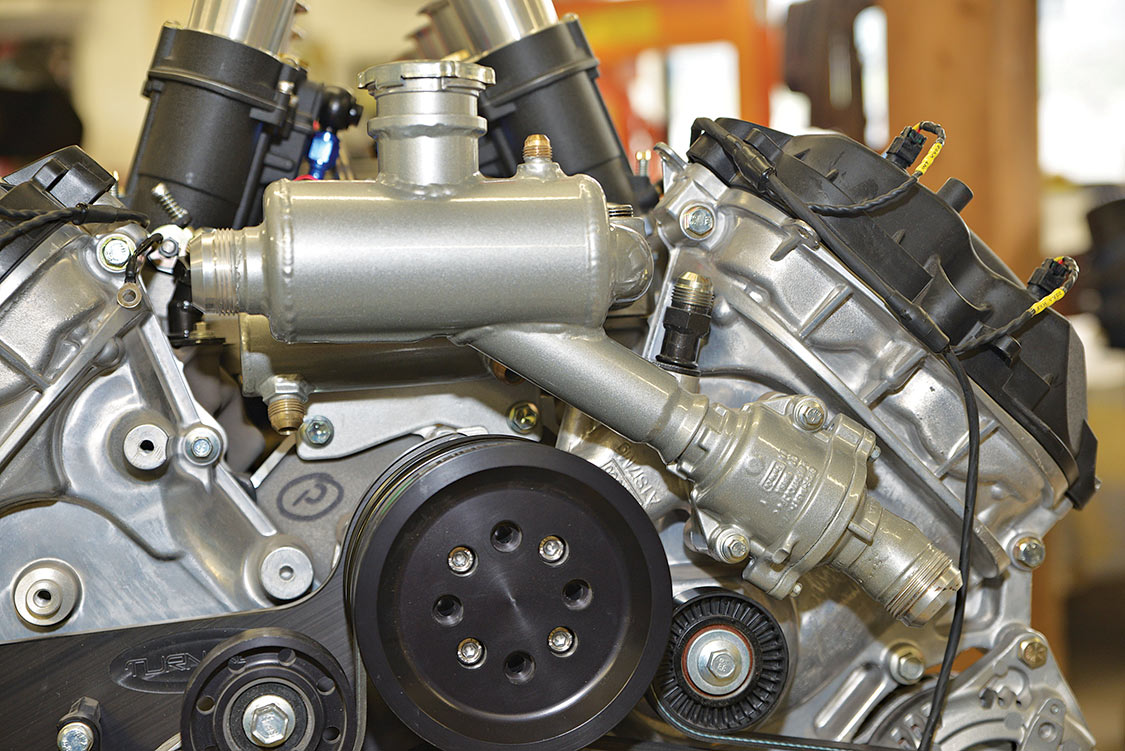

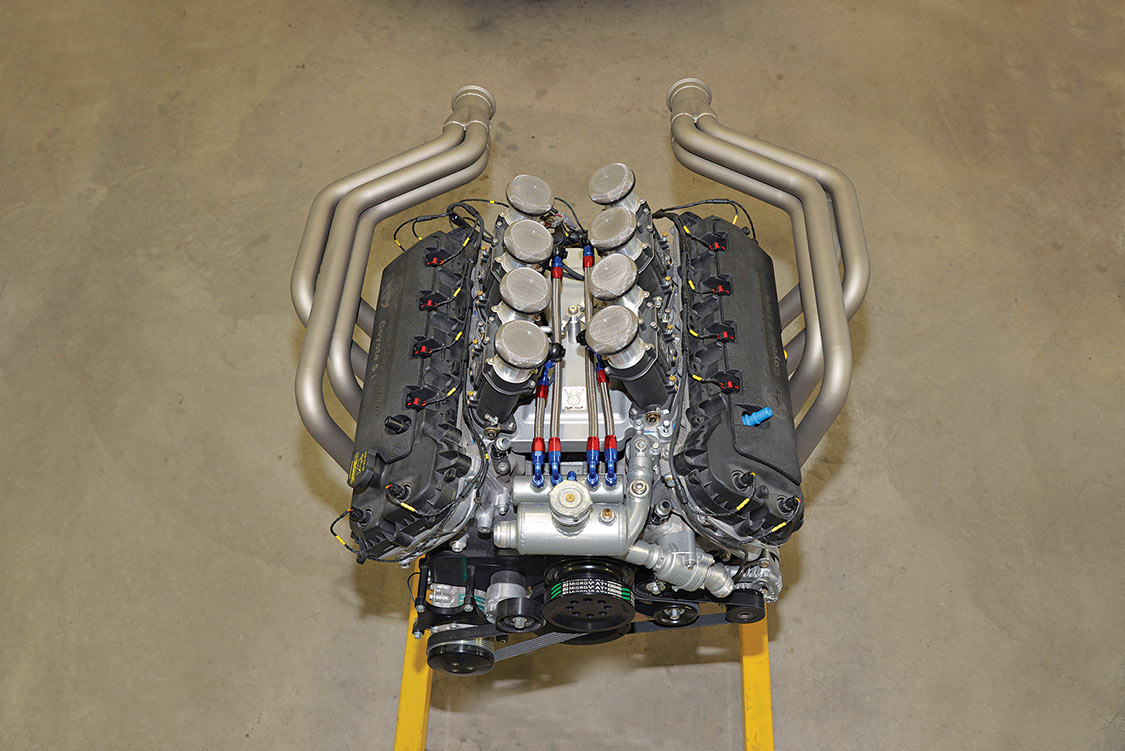

For those who are new to this, Ford Racing’s all-aluminum 5.0-liter Mustang crate engine is a modern 5.0-liter 32-valve dohc V-8 that uses advanced features such as Twin Independent Variable Camshaft Timing (Ti-VCT) to deliver 420 bhp at 6500 rpm and 390 ft.-lb.-plus of torque at 4250 rpm (with premium fuel). The lightweight aluminum cylinder block features cross-bolted main bearing caps and thick main bearing bulkheads for bottom-end strength. Optimized oil drainback and windage control improves high-rpm performance. The headers that come with the engine are designed for any late model Mustang, or an early model Mustang that has chassis modifications, or early street rods or pickups. These headers can be used by hooking an exhaust system to them, and they work very well.

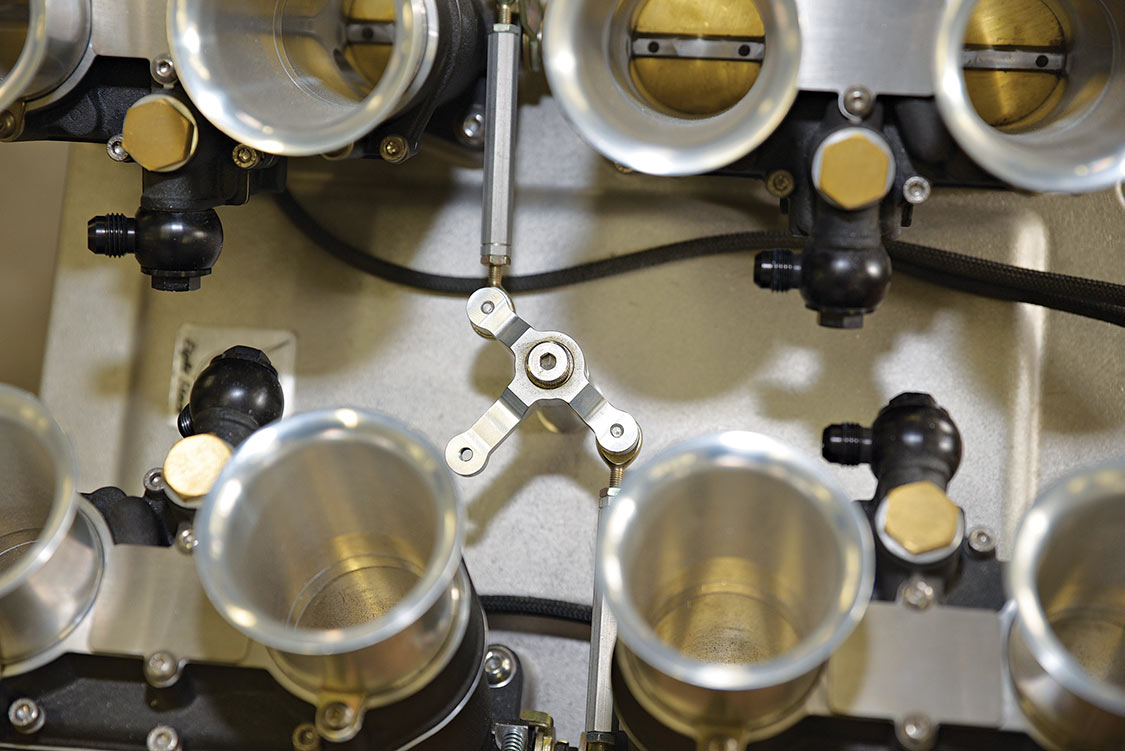

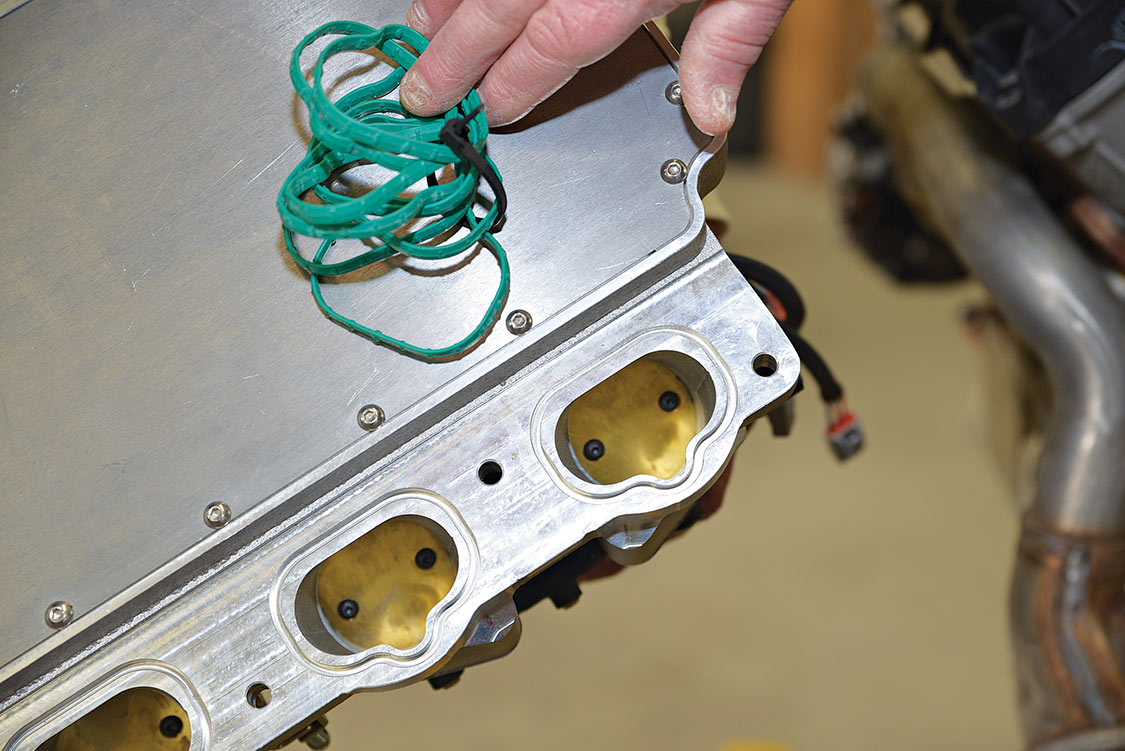

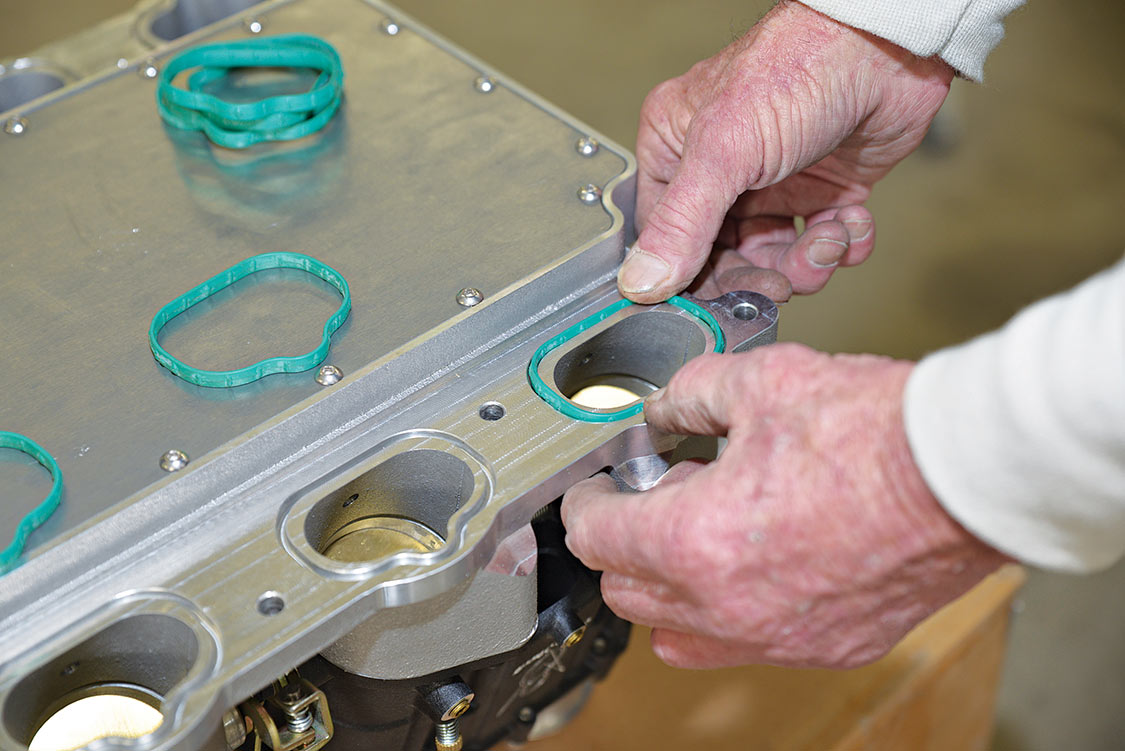

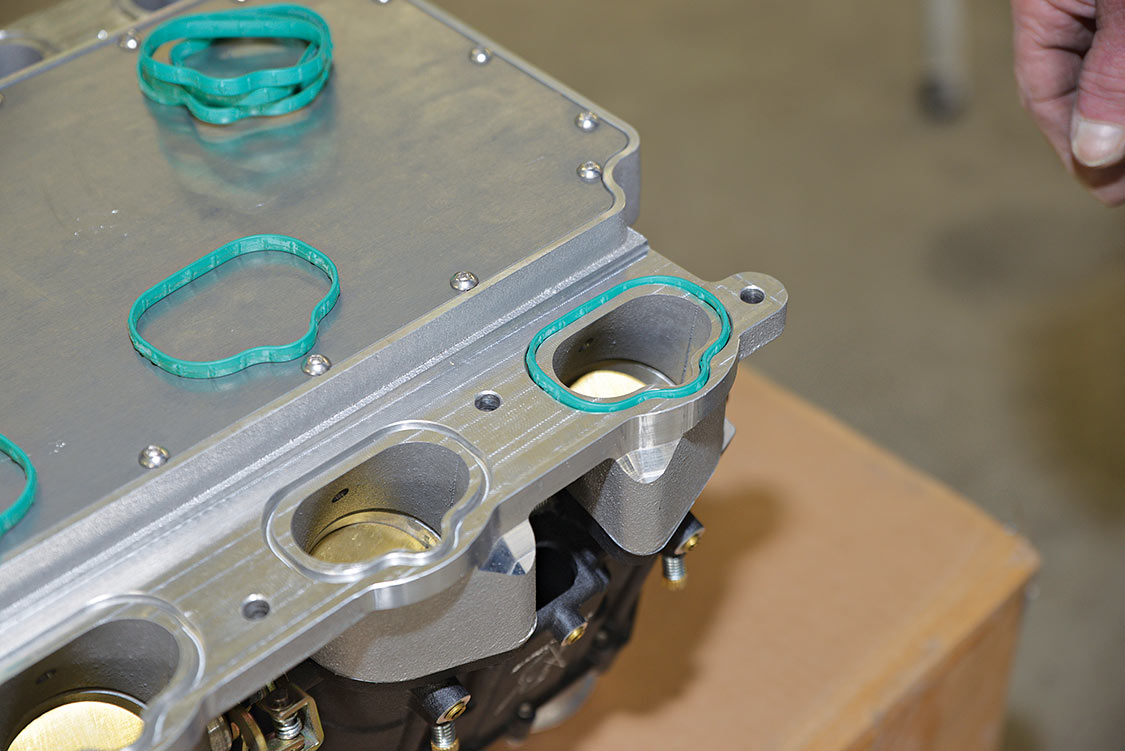

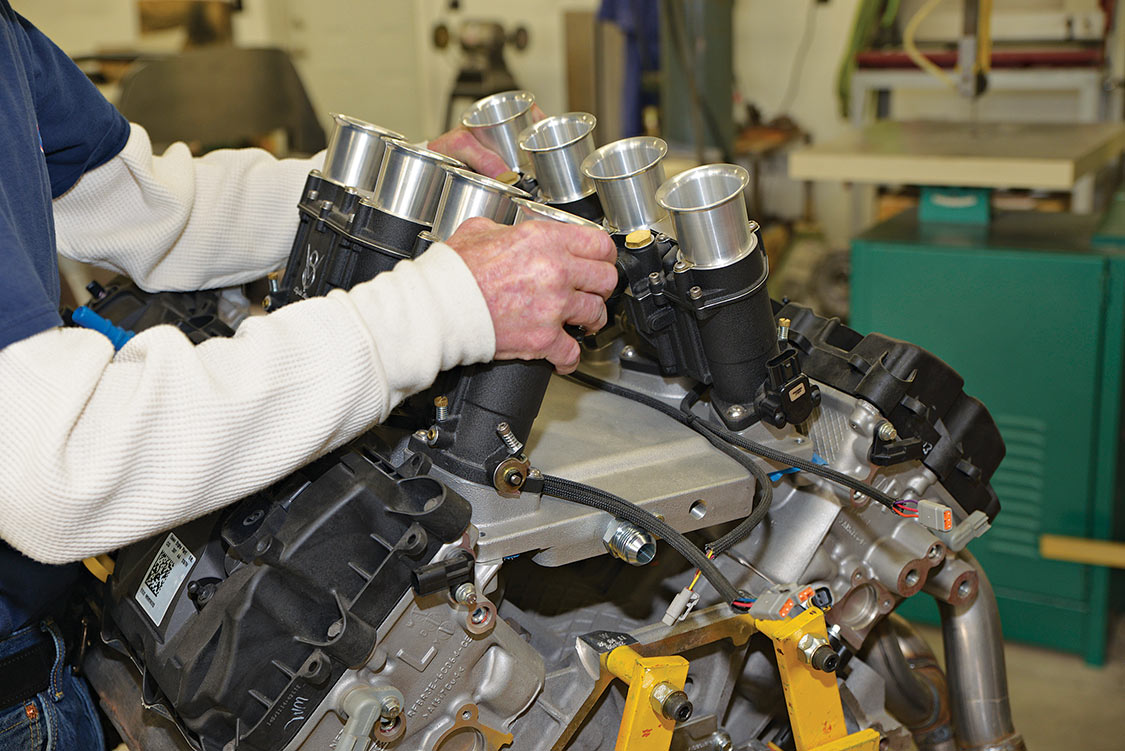

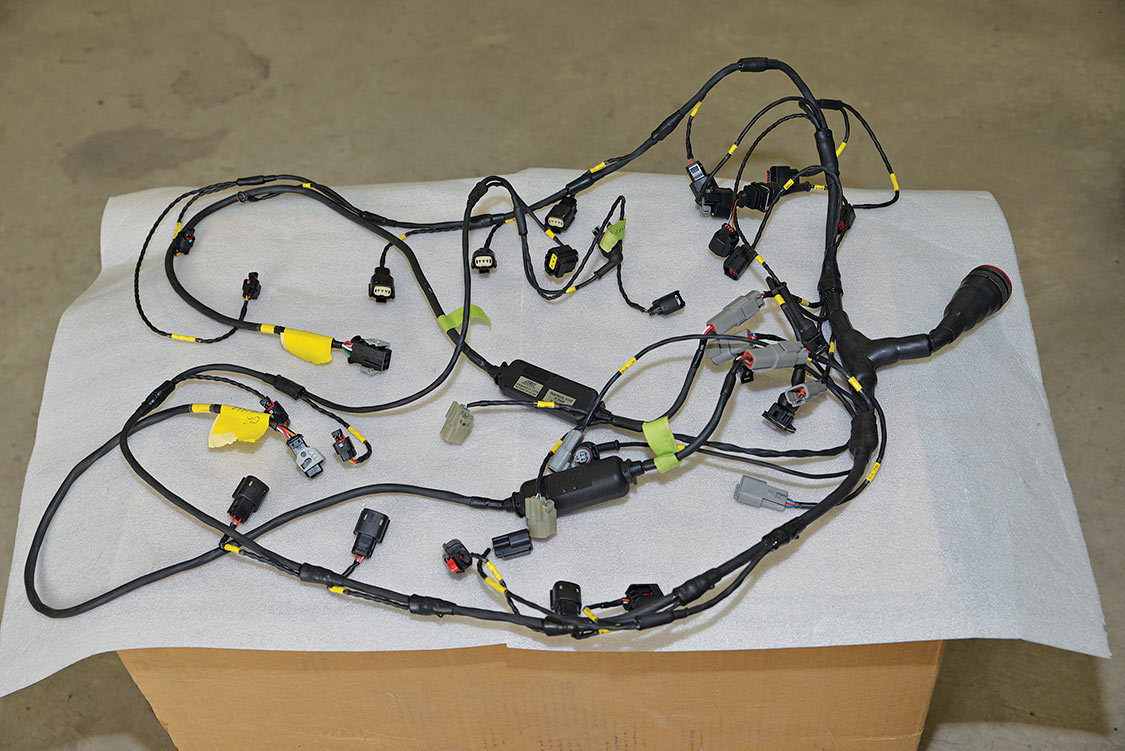

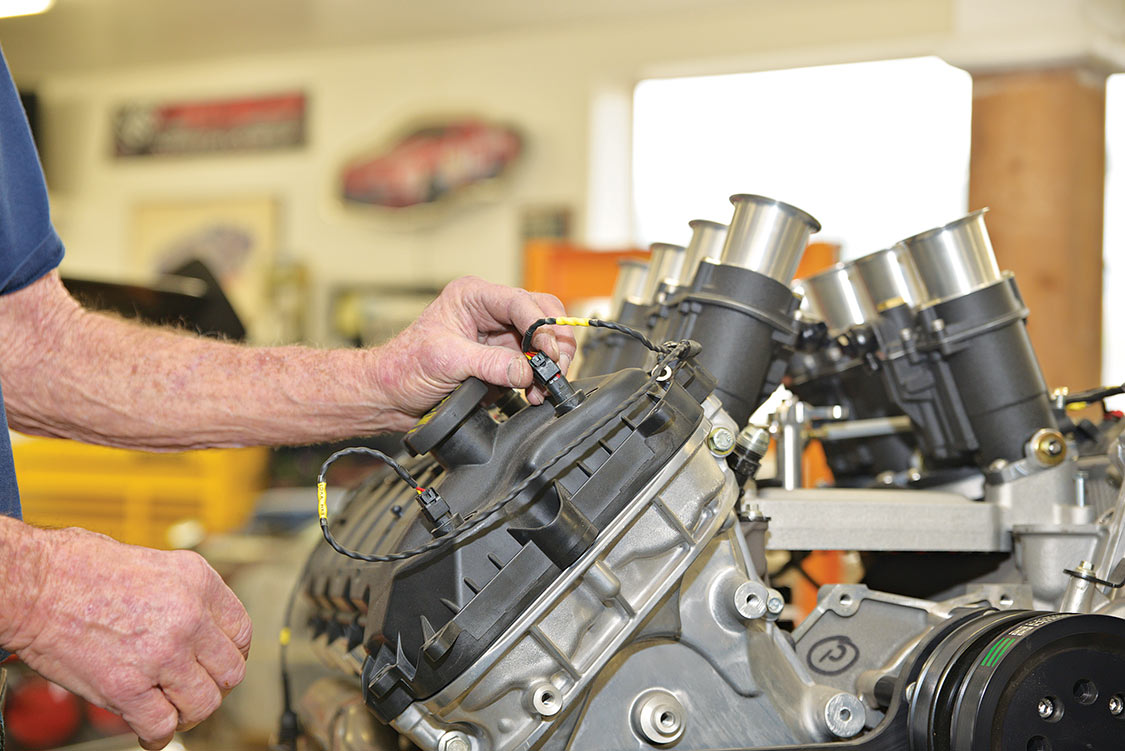

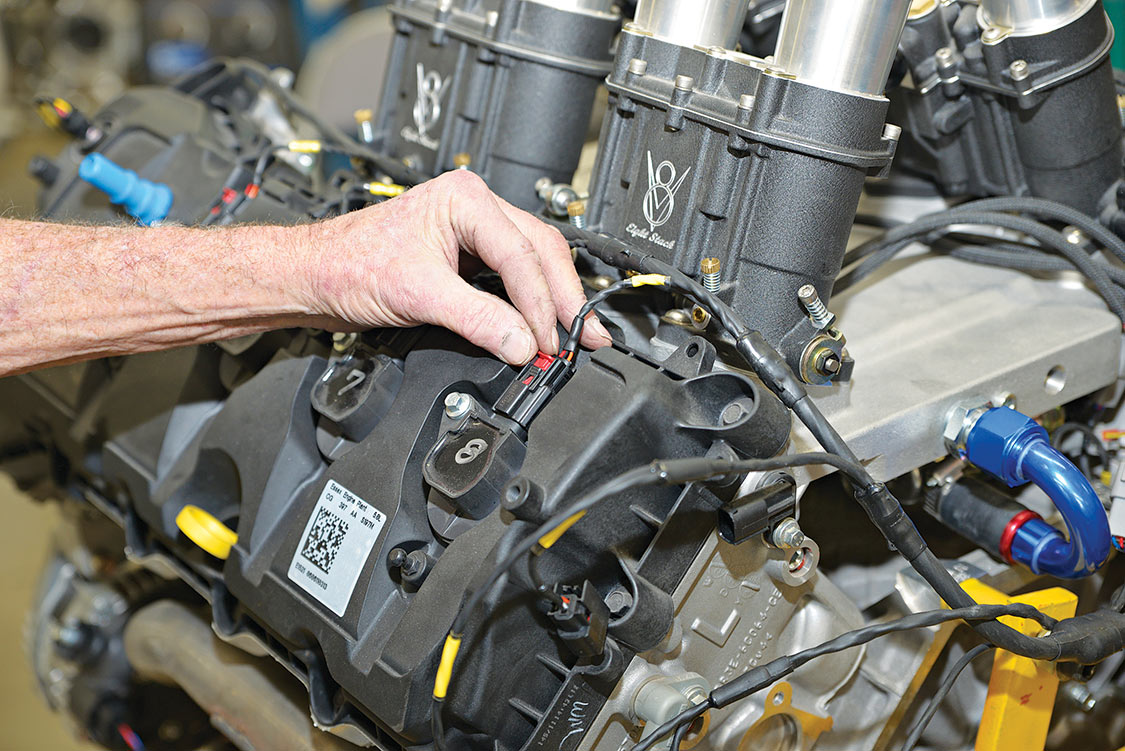

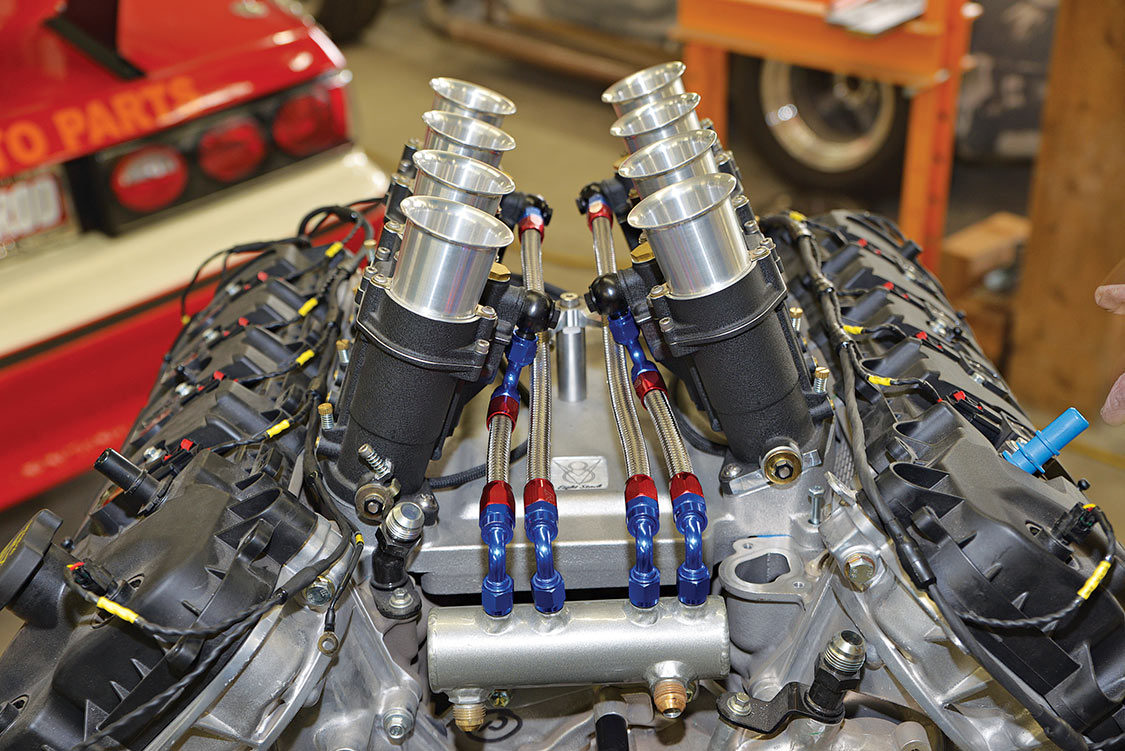

Now comes the rub. Merrell and his crew want to use the sexy, exotic, 8-Stack fuel injection system. It puts out more power than the stock fuel-injection unit, and it has the retro look of the 1960s. The only problem was that no one made the intake manifold, or the wiring harnesses or the computer for that matter, to make it all work. “Well, I approached Bob Hockenberry, who at that time owned 8-Stack Injection, and Dale Schaller, his number one guy, about building the mechanical system for the Ford Coyote configuration,” says Merrell. “And they both got on board with it in very short order.” So Merrell ordered three of the Coyote crate engines from Ford. Two of the engines were shipped to his shop in Sequim, Washington, for fitting purposes in the two GT40 cars. The other engine was shipped to 8-Stack in Youngstown, Ohio, so they could do the pattern work and engineering to build the manifold and the Weber look-alike throttle bodies with the internal fuel injectors.

“The whole concept behind this was to build a 21st century technology engine, with 1965 looks, and do it with a computer system that is plug-and-play,” says Merrell. “The other important goal was that there was to be no after-install tuning.”

The only way this concept could be utilized was by having a consistent engine supply with a consistent base, with no internal modifications. So the Ford Coyote engine at that time was the perfect choice, not only because of technology that was in it, but also because Ford Motor Company came out and said that that was going to be their performance engine for the next 10 years, and it was also going to be their production motor for their Mustangs and light trucks.

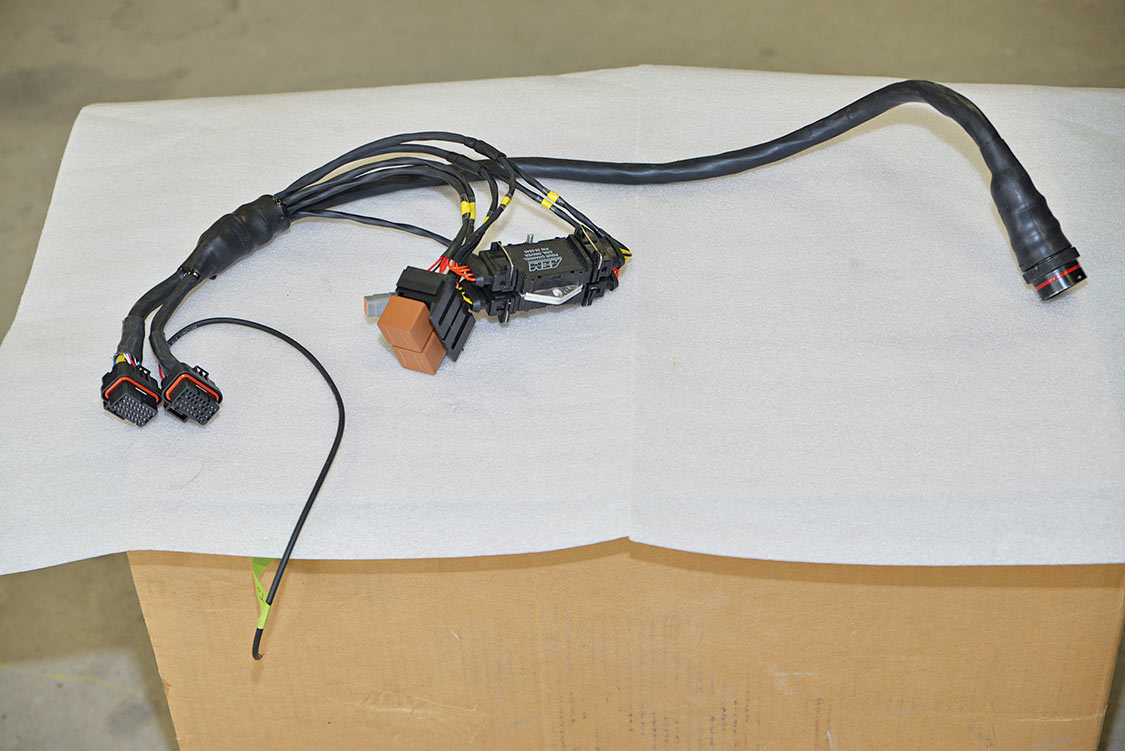

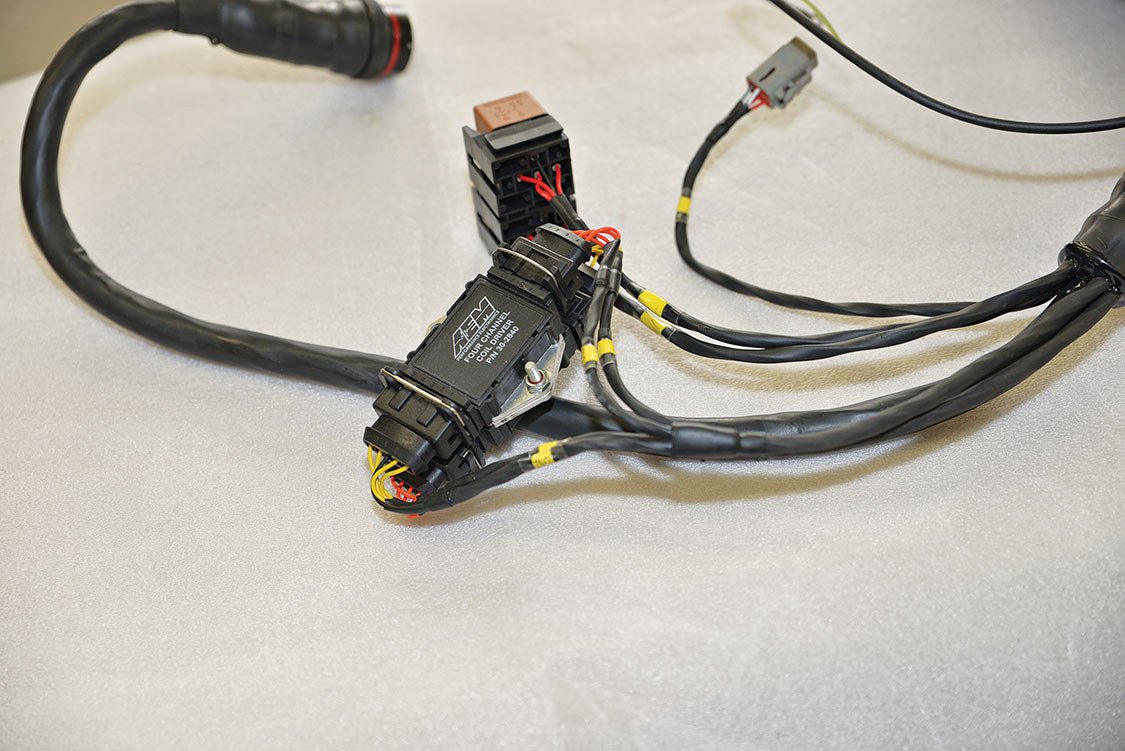

The Coyote is a ready-made base engine platform. Ford’s engine program supported Merrell’s idea to build a computer program to make it plug-and-play, with the idea that it could be used in other applications. As it turned out, it’s taken a year and a half to put the mechanical parts together on the engine. Then it’s taken another year and a half to find a quality computer manufacturer, and a quality programming company, to build the program. “The computer and the program are the brains,” Merrell says. “We needed these two companies to satisfy my ideas as far as building a real out-of-the-box plug-and-play aftermarket fuel-injection system that looks like 1965 Weber carburetors.”

The engines being used are right out-of-the-box, 5-liter, 302-cu.-in. and weigh 400 lb. each. This is 60 lb. less than the original small-block Ford. This is the only normally aspirated engine that’s ever been designed and built capable of 1.5 bhp per cubic inch. That tells you how good the design is.

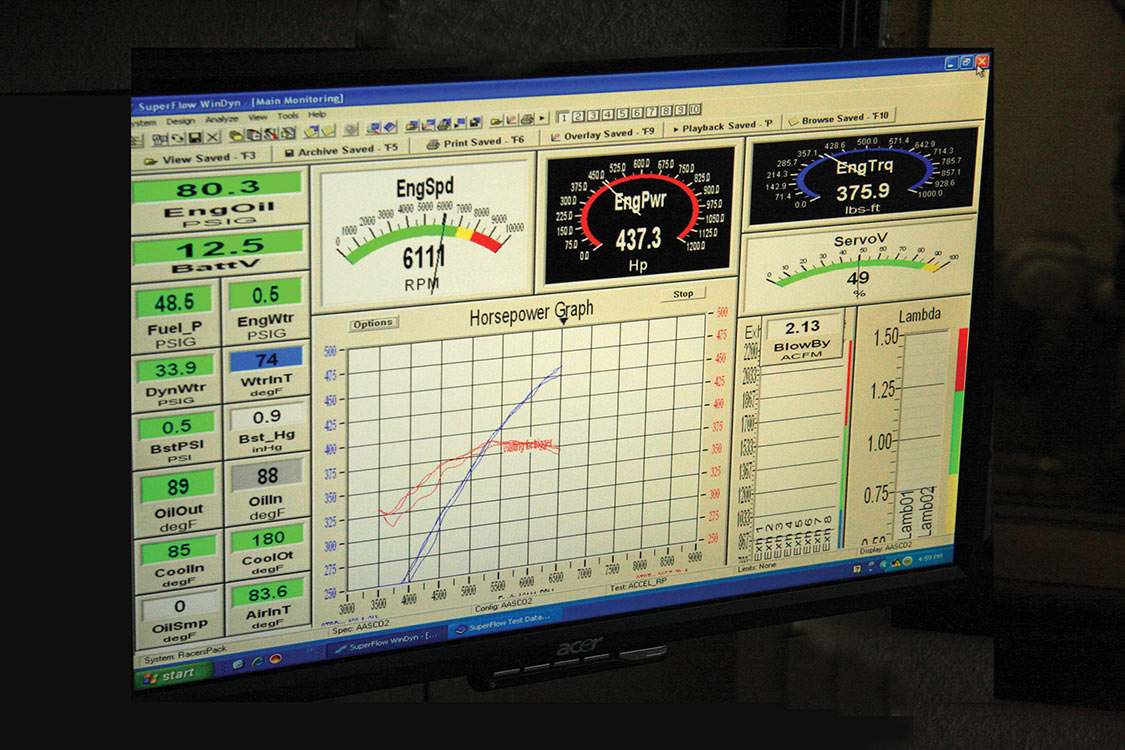

The next obstacle, once they got to the point of seeing a reasonable time frame for having the dyno work done and the computer program built and functioning, was they needed a test bed.

The two Mark 4 GT40s were not and are not even close to being completed. So, late last year Merrell worked out a deal with Karen Salvaggio to purchase her old Factory Five Daytona Coupe. It was a dedicated race car and had been retired when she built her new Daytona Coupe.

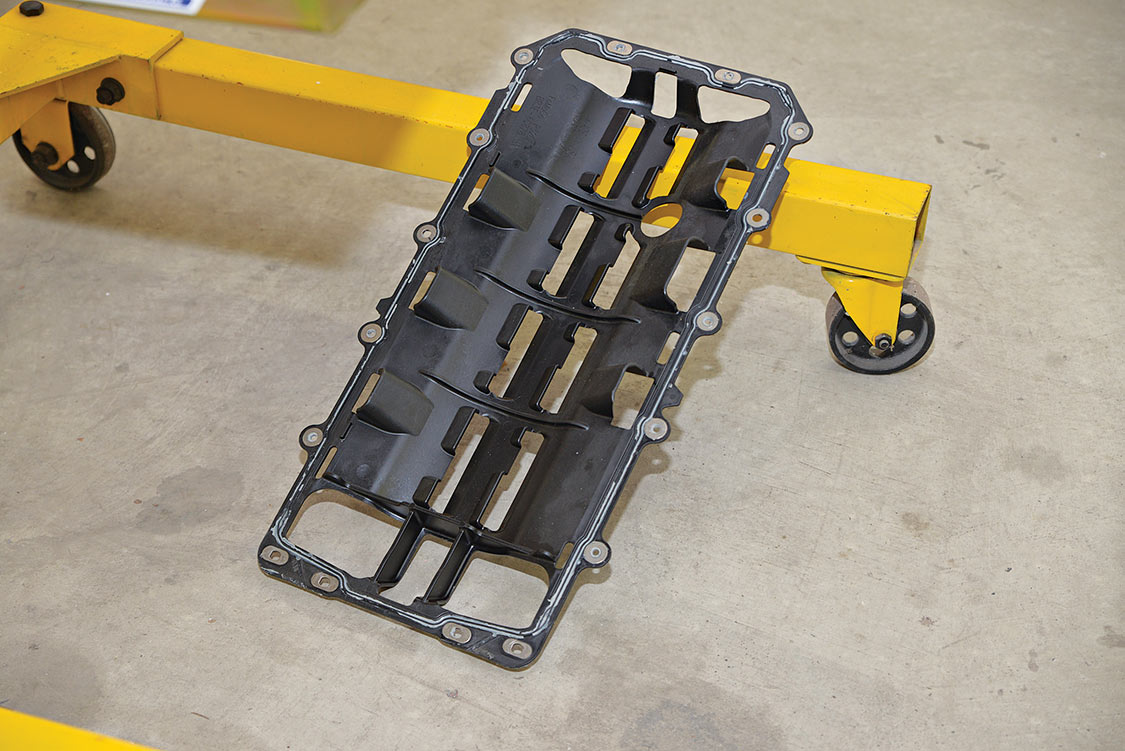

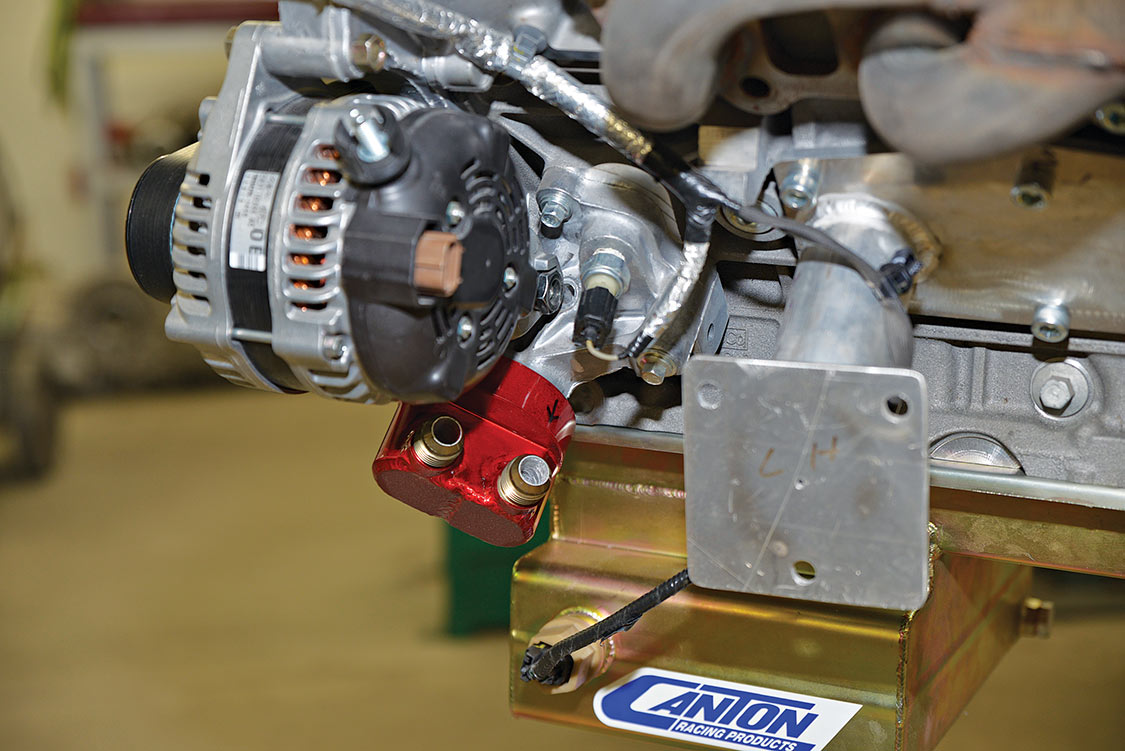

So here’s how it works. For this application, the Canton oil pan is installed on the engine. The stock Ford pan is a rear sump operation. This engine was designed for the Mustang and they had to go to the rear sump pan because of the “K” member. Most of the performance applications don’t have a “K” member so they use front sump pans rather than rear sump pans. It’s a better system because the oil is closer to the oil pump, which means less chance of a cavitation problem. Not every vehicle will accept the front sump pan and, if that’s the case, we use the stock pan. Also the Canton oil pan is used with this engine because it has a deeper front sump.

Share Link