PHIL GORDAN

.

January 30, 2024

.

Street Trucks

PHIL GORDAN

.

January 30, 2024

.

Street Trucks

The people who make up the truck-building culture come from all backgrounds, from a parent teaching a child to someone who is just naturally good with their hands. Growing up the in the construction world, Justin Wallace could build an ark if he needed to. He was born and raised in Bluffdale, Utah, a city that has just under 8,000 residents, and Justin learned that what you can do with your hands comes in handy.

“I was constantly helping everyone in the city with everything I could possibly help with,” Justin tells Street Trucks. “I was always able to help people.”

Justin had to constantly travel through the city with supplies, so it made sense for him to purchase a truck. He figured a Chevy or Dodge would be a good choice, but when Ford’s 2018 truck body style was released, Justin knew it was something special.

“I remember the first time I saw the Ford,” adds Justin, “It was nasty, and I knew I had to get it.”

Justin went into a local Ford dealership, purchased the brand new 2018 Ford F-350 Platinum, and headed straight to his shop to start the teardown process.

Justin is very visual, and his building process is like no other we have seen. Instead of slapping parts and pieces on to see how they look, he takes a pencil and paper and draws out what he wants to do. Instead of a trial-and-error process by putting things on that eventually don’t fit or that don’t cohesively look appealing, Justin uses a visual guide from his drawing.

Knowing what was in the works, Justin pulled off the factory suspension and everything that he would eventually replace.

“I think I spent a whole day cutting and smoothing,” Justin adds.

After all factory non-used items were removed, it was the start of the build.

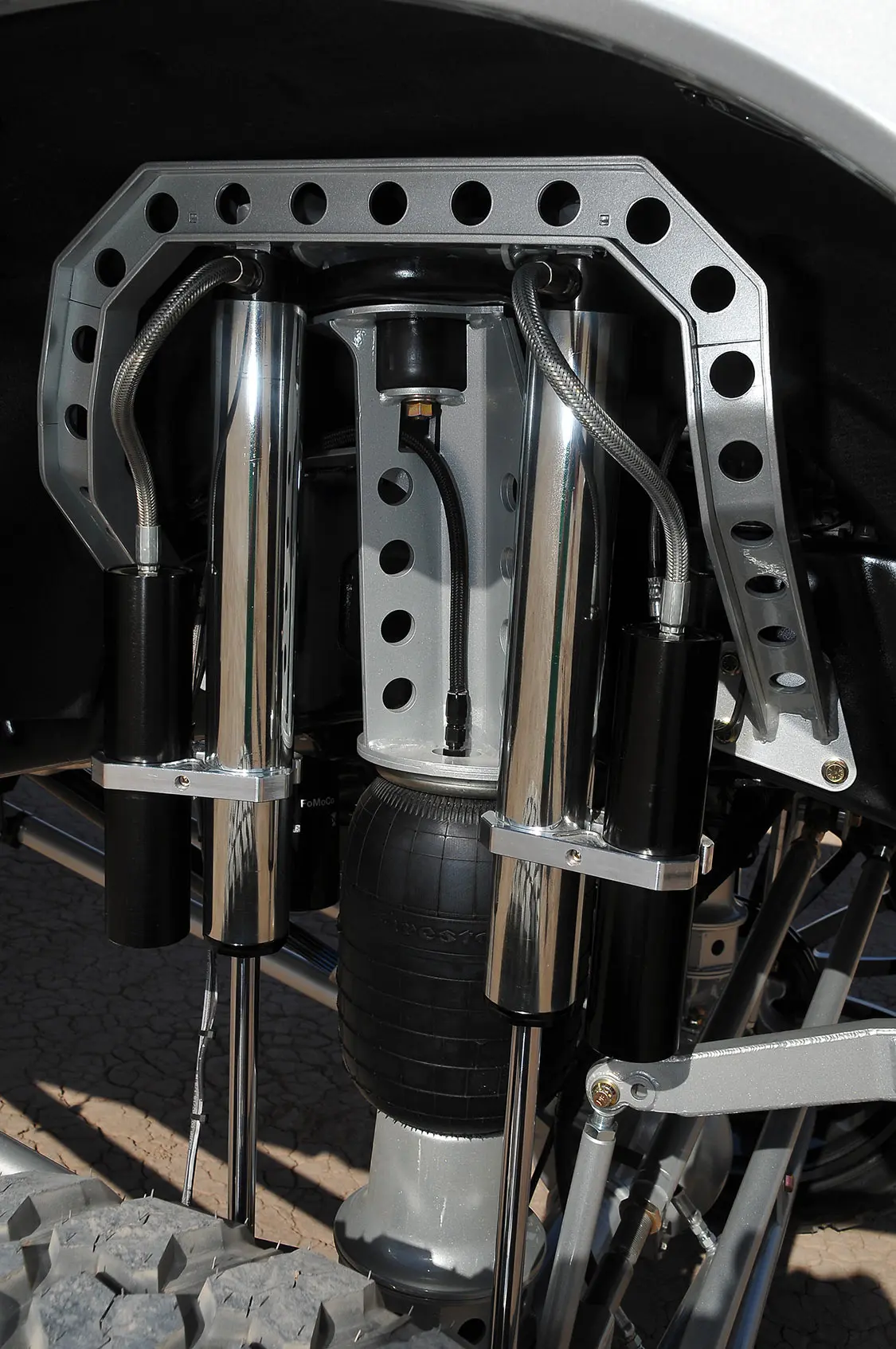

Justin designed a full mock-up of the air-ride suspension with Ultimate Air Ride products. The company’s kit requires very few holes to be drilled, but there still were some. Once the design was done and mastered, Justin began the process of getting the cradle up on the frame, setting up the axle brackets, and working on the link bars.

The suspension parts were sent off to the powdercoater as Justin began the process of getting the Accuair system in motion. After thinking long and hard about where to put the tanks and compressors, he decided to insert the four Endo tanks in the bed wall, flush-mounted. Making sure that all the air lines would handle brutal conditions, he chose AN fuel lines that hold up to 1,000 psi.

Justin knew he didn’t want any bolt-on brackets, so he mocked up a design with his axles and marked where he would weld tabs on everything. The Signature Metal Fab Torsion sway bars were added and proved to be a simple addition for him.

With a week left at the powdercoater, Justin turned his attention to the performance part of the Ford. The factory exhaust was removed and the JAMO 5-inch exhaust was booted up. The next step was to ensure the diesel could breathe by bolting in the MPD intercooler piping and intake. The PPEI tuning was uploaded on his EZ-Lynk and flashing the best tunes.

The headlights were sent out to Precision Retrofits to be custom painted, and 32 BAMF LED lights were mounted throughout the truck. Justin did a full drawing of every last pod to make sure they not only fit, but also used the least room possible. At this point, the air-management system was back and installed by Justin in the shop.

With time ticking down, Justin knew how close he was and stepped into second gear to work on the final lap of Swanky. He pulled out a tape measure and aligned the Ford with no issues. One week left before the SEMA 2018 show in Las Vegas, where he planned to debut the build, Justin added the Wilwood disc brakes and mounted and drilled the rotors and calipers.

Only one last piece was left for Swanky: wheels and tires for the new lifted Ford F-350. He had just received 30×16 American Force wheels but still needed rubber for them. Five days before the truck was loaded on the transport truck, the Fury tires showed up. Justin took them to the local tire shop to be mounted. The wheels and tires were brought back to Justin’s shop where he installed them on the Ford. Once completed, Justin stood back and for about 30 minutes just stared in amazement at what he’d accomplished by himself.

Swanky took a month to build and will be used as a rolling billboard for Justin’s businesses.

Owner

Chassis

Drivetrain

Body/Paint

Interior

Wheels & Tires

Special Thanks

Thanks to all my sponsors for providing the best-of-the-best parts, and John and Jason from American Force Wheels for everything they do to push the industry to a new level and for trusting me to build something great. Thanks also to my family and friends who support me and push me to keep going but mainly one person, my girlfriend Brittany.

Share Link