BOBBY STEWART

.

April 26, 2023

.

All Feature Vehicles

BOBBY STEWART

.

April 26, 2023

.

All Feature Vehicles

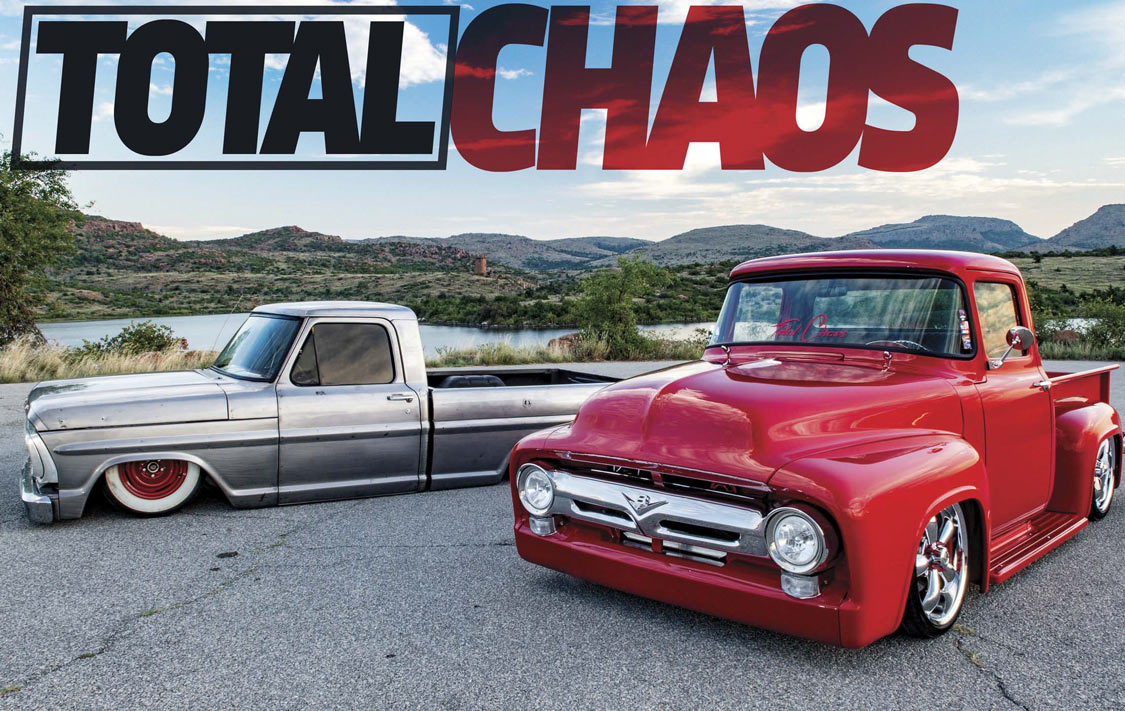

We understand that dropping $50K-$100K on a truck build is simply not feasible for the majority of us, but when we came across two unbelievable Ford trucks from the same area in Oklahoma, it’s only fi tting that we show our readers the level of success you can achieve by not being afraid to take a chance on building your own truck. Simply put, these Fords are the fi nal reward for countless hours of hard work and determination invested by two guys with DIY attitudes and endless motivation.

When we first met Addison Augusta and Jeremy Pendergraft, it was very clear that they not only shared the same passion for custom trucks, but also the desire to be the driving force behind every aspect of their builds.

Addison summed up his feelings quite simply by saying, “We’re just two guys who built their own trucks. To me, it seems like it’s rare to find people who build their own cars anymore.”

While it is true that both of these Fords fall somewhere within the same build budget spectrum, the road Addison and Jeremy took to get there was quite different. In the end, both managed to build head-turning custom trucks without breaking their bank accounts.

IT WAS SUNDAY morning when Addison Augusta received the call that lead to a chance meeting and ultimately an offer that he would not be able to refuse.

“My mom called me to help move a China hutch that a friend was giving her,” the Cache, Oklahoma, resident recounted. “I get there, and I see an Olds 442 in the driveway.”

Eventually, Addison met the owner of that Olds, an older gentleman, who mentioned to Addison that he had one project too many—namely a 1956 Ford F100. He also mentioned that he had a few “extra parts” to go along with it, but there was a catch. The truck was in countless pieces and needed to be completely rebuilt.

Addison left agreeing to think it over. He wasn’t necessarily “in the market” for a Ford truck, after all. But the off er seemed too good to pass up, and Addison quickly found himself returning, this time with a trailer in tow. Once they began to load the trailer things took an even better turn when the previous owner revealed that he had been stockpiling parts to restore the Ford and would even follow home Addison with his own trailer full of extras.

Over the next year, Addison sorted through the parts, selling the ones that didn’t fit his style and buying new parts that did. He also picked up a donor 2003 Ford Crown Victoria Police Interceptor that he intended to use for the suspension and drivetrain.

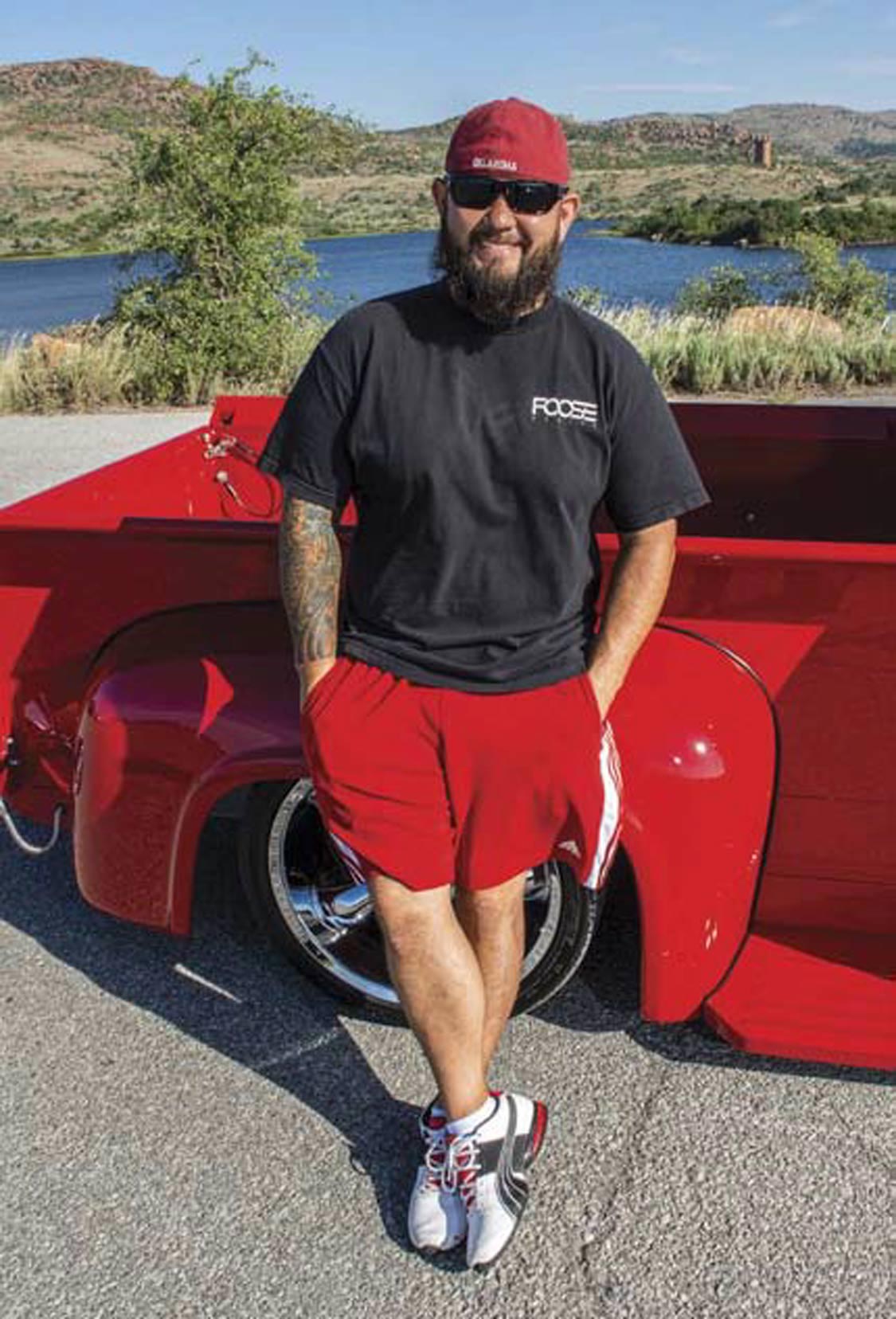

Within a year, Addison was ready to start building and turned to his own backyard to do so. “Built not bought” is not just a quirky catch phrase to Addison, but something he takes great pride in. He doesn’t own a commercial shop or car bay, just a basic garage to build the truck of his dreams. He says building the majority of his own truck gave him a sense of pride.

“WITHOUT DOUBT, THE MOST EYECATCHING FEATURE OF ADDISON’S FORD IS THE BRIGHT RED PAINT. FOR THIS HE TURNED TO JUSTIN BYRD AT BYRDMAN KUSTOMZ IN LAWTON, OKLAHOMA, FOR ASSISTANCE.”

“I did this and I am proud of it,” he says, quickly adding, “At the end of the day, I guess I’m really just cheap!”

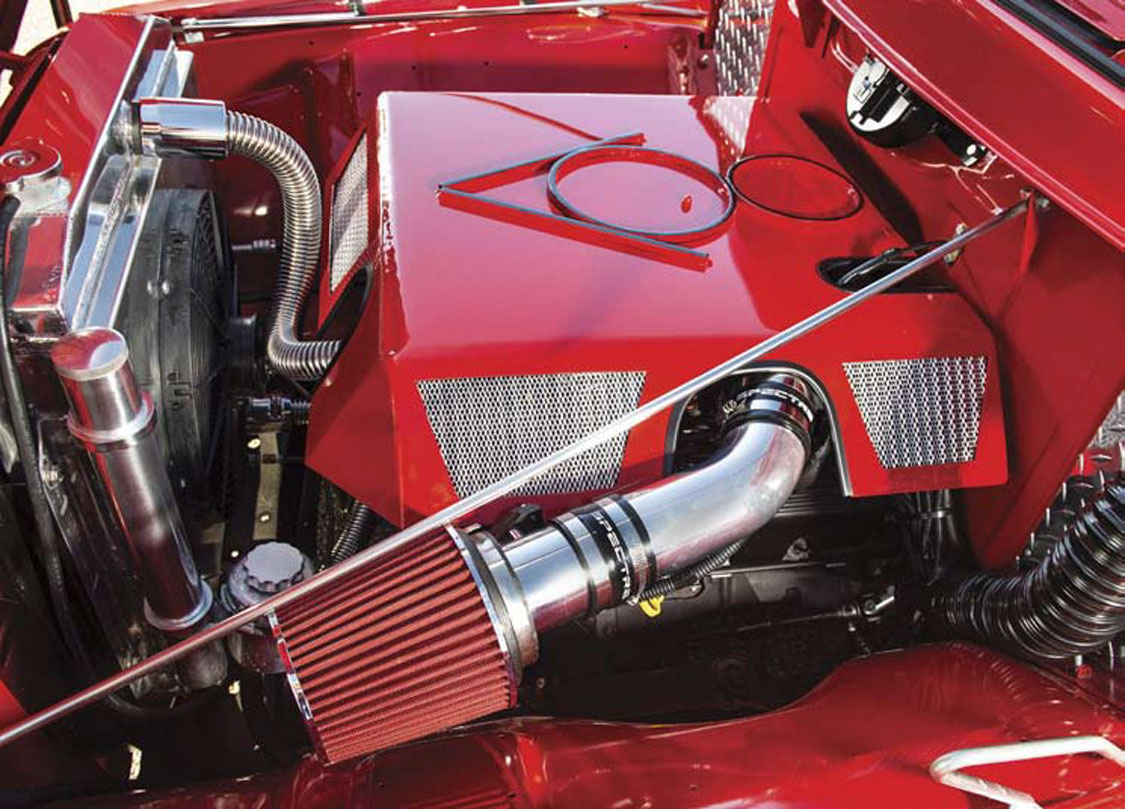

Addison tore the truck completely down to the frame, boxed in the back and cut off all of the “extras” before sandblasting. He grafted the front end from the donor Crown Victoria and used a universal triangulated 4-link on a 1997 Ford Explorer rear axle. The rebuilt and freshly repainted frame rides on RideTech Shockwave airbags with 3/8-inch Slam Specialties valves controlling the ride height. Addison then pulled the 4.6-liter engine and transmission from the Crown Victoria to prep and install. He handled the motorwork himself by refreshing and repainting it so he’s sure it’s reliable. The fi nal step was to mate it back to the freshly rebuilt transmission thanks to Rick Garner’s Transmission Shop.

Addison also handled the body work himself, replacing floor pans, rockers, cab corners and shaving items such as the gas tank hole, antenna, keyholes and drip rails. The original truck had a lot of rust, so he spent many hours cutting, welding and grinding. The Ford features tilt bed and forward tilt hood to help better display Addison’s work and craftsmanship.

Without doubt, the most eye-catching feature of Addison’s Ford is the bright red paint. For this he turned to Justin Byrd at Byrdman Kustomz in Lawton, Oklahoma, for assistance. The original idea called for a two-tone paint scheme, but after a lot of second guessing, Addison kept it simple with Race Red. Justifi ed Details of Lawton, Oklahoma, then added ceramic coating that brought out the Race Red base to an entirely diff erent level.

“I really think the coating makes it pop,” Addison says. “When I built the truck, I built a driver. After we got the truck back from paint, it turned into a show truck.”

Since entering the show circuit, Addison’s Ford has managed to walk away with several “Best of” awards including several for Best Paint.

Early on, Addison was content with the original interior that came with the truck, but the black tuck and roll was fading and not up to the same level as the rest of the truck. It needed to be replaced. For this, Addison sketched his own design and asked JC’s Upholstery in Snyder, Oklahoma, to stitch it for him. The Ford’s interior has a very classy feel with black ostrich and red diamond tuck as the main theme, accented by a painted dash and billet and chrome throughout the cab.

“WHEN I BUILT THE TRUCK, I BUILT A DRIVER. AFTER WE GOT THE TRUCK BACK FROM PAINT, IT TURNED INTO A SHOW TRUCK.”

With the truck now completely back together and quickly gathering attention both online and at shows, Addison has simply been enjoying the fruits of his labor.

“I took a truck that was laying on the side of the house, in pieces, and completed it,” he told us.

But, Addison is not finished by any means. He has future plans that include staggered offset wheels, wider fenders and airbrush work.

While Addison completed the majority of the build himself, he was quick to point out that he also had a lot help of others to complete it.

“Jessica, my wife, we do everything together,” he says. “We do all of our shows together. Ninety percent of the truck I built in the garage, but she would help me. She never complained. It makes is so much easier when you have somebody to support you.”

Addison also thanked Brandon Young for helping him with the electric during the build.

AS A TEEN, Jeremy Pendergraft from Hollis, Oklahoma, used to flip through the pages of his favorite truck magazines, dreaming that he would someday build his own.

“When I was growing up, I would see trucks that were perfect, and it felt unreachable,” he recalled.

Fast-forward to present day. Times have changed, attitudes have changed, and Jeremy was sitting on a custom gold mine of family-owned trucks to work with. His wife ultimately provided the push he that needed to turn an old work truck into the low, mean badass he wanted without emptying his wallet in the process.

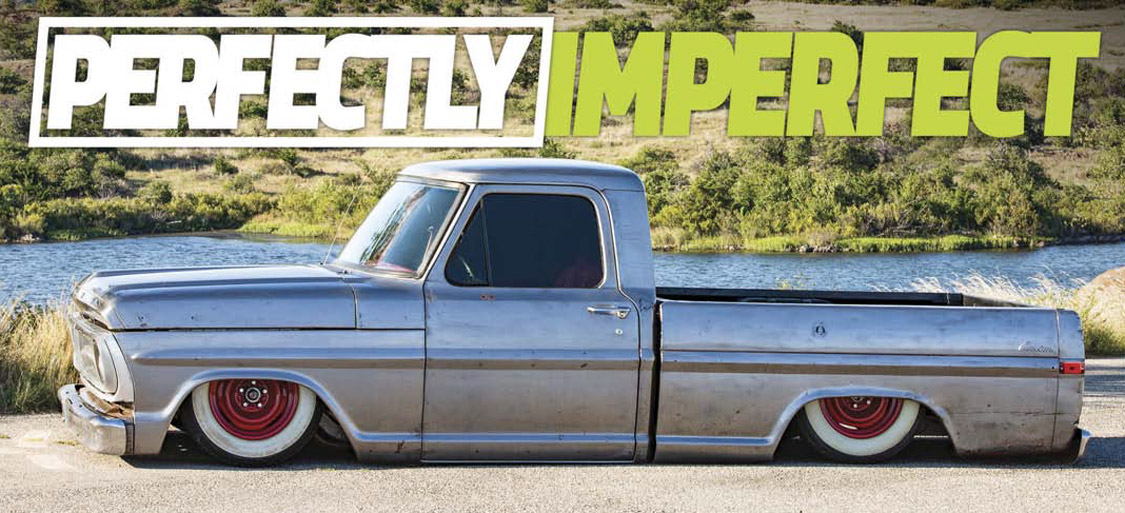

Jeremy is self-admittedly known as a Ford guy. He is the only Ford guy in his group, so it made sense that he wanted to build this 1971 Ford F100.

“I was always told you can’t make a Ford lay out,” he says. “I had to prove them wrong.”

As luck would have it, there was an old ¾-ton sitting outside not being used.

“The truck had been in my family for a while,” he says. “It was a ¾-ton with a camper. It was parted out and sitting in a field.”

However, to make a complete truck, he was going to need a new bed. While he had access to several old trucks, he did not have a bed he could use, so he looked at outside sources. A local farmer had a step-side bed for sale, but Jeremy saw something better: a bed that had been converted into a trailer. The 1971 short bed had been converted to into a deer corn trailer and the farmer had been using it for years, but it was exactly what Jeremy wanted, so he offered to buy it on the spot.

“That old man thought I was crazier than hell,” Jeremy laughingly joked.

While the bed was a good find, it also needed a lot of time and attention. Jeremy’s wife bought him a stud puller and he handled the task of straightening the body himself. The bed floor was completely rusted out, but Jeremy had planned to build a new, raised floor anyway. To complete that, he employed his wife and son, and together they raised the bed floor and fenders, using a set from an old 1966 Ford he had rolled in an accident as a teenager.

“I think that’s one of the coolest things about the whole truck,” Jeremy explains. “My entire family was there. Everybody had a say so in the process.”

The bare metal skin of Jeremy’s Ford is an instant eye catcher. Since the Ford was built using multiple trucks, the idea was to sand it down to metal, clear coat it to preserve it and then eventually paint it. To complete that, he also turned to his family for help.

“We took it down to the bare metal because we were going to try to paint it,” Jeremy says. “The truck started getting so much attention as bare metal, we loved it and decided to keep it.”

What can easily be overlooked due to the simplicity of Jeremy’s Ford is the solid frame work that lies hidden beneath the shiny body.

“The truck is not body dropped; the frame is custom,” he says. “I wanted it low. I wanted it stupid low and I feel like I achieved it.”

The Ford’s 2×4 rectangular frame features the entire front suspension from a donor 1985 Lincoln Town Car, which was refreshed and a custom 2-link in the rear fabricated by the owner. Jeremy painted the frame metallic silver and installed Airmaxx airbags and toggle switches lift his truck from “stupid low” to ride quite effectively.

For power, Jeremy originally planned to use a Ford 390. As it turns out, the 390 was too tall and would have stuck out of the hood by nearly 8 inches. Jeremy wanted a flat, stock hood so he turned to the Ford 302 and transmission from the same donor 1985 Lincoln Town Car. The Ford 302 has been rebuilt and features an Edelbrock Performer intake manifold, carburetor and headers that Jeremy picked up from a swap meet. The exhaust flows through Flowmaster mufflers.

After being unable to find a set of wheels that he liked, Jeremy turned back to the donor 1985 Lincoln Town Car. He simply painted the wheels from the Town Car red and has used them since.

“I’ve tried changing them since, and it doesn’t look right,” he says. “I even tried some Torque Thrust wheels on it and didn’t like it.”

The original truck had a padded dash and a lot of wood grain, and quite frankly, Jeremy hated it. The interior now consists of the instrument panel and doors from a 2 ½ ton wheat truck and a bench seat that was gifted to him from a 1994 Chevy truck. M&R Upholstery in Altus, Oklahoma, recovered the seat in red vinyl. The custom shifter is actually an old antique torch that he picked up from his dad’s collection and is easily the attention piece of the Ford’s interior.

Since completion, Jeremy’s Ford has been gaining a lot of attention from others and at shows, much to the surprise of the owner.

“I had no intentions of it ever being a show truck,” he says. “It was definitely built with junkyard parts for sure.

” With a total cost of around $3,000, Jeremy’s Ford is the definition of budget build.

Jeremy wanted to say thanks to those who helped him along the way, including his wife Kaesi and son Jaydon.

“Everybody kind of dreams of building things with your dad,” he says. “I was able to do that with my son, so that was pretty cool.”

He would also like to thank his dad, Brian Gollihare from Midway Motors, and Mark Whiteskunk and Kyle Davis’ help with the airbag system.

Share Link