Ro McGonegal

.

July 11, 2022

.

All Feature Vehicles

Ro McGonegal

.

July 11, 2022

.

All Feature Vehicles

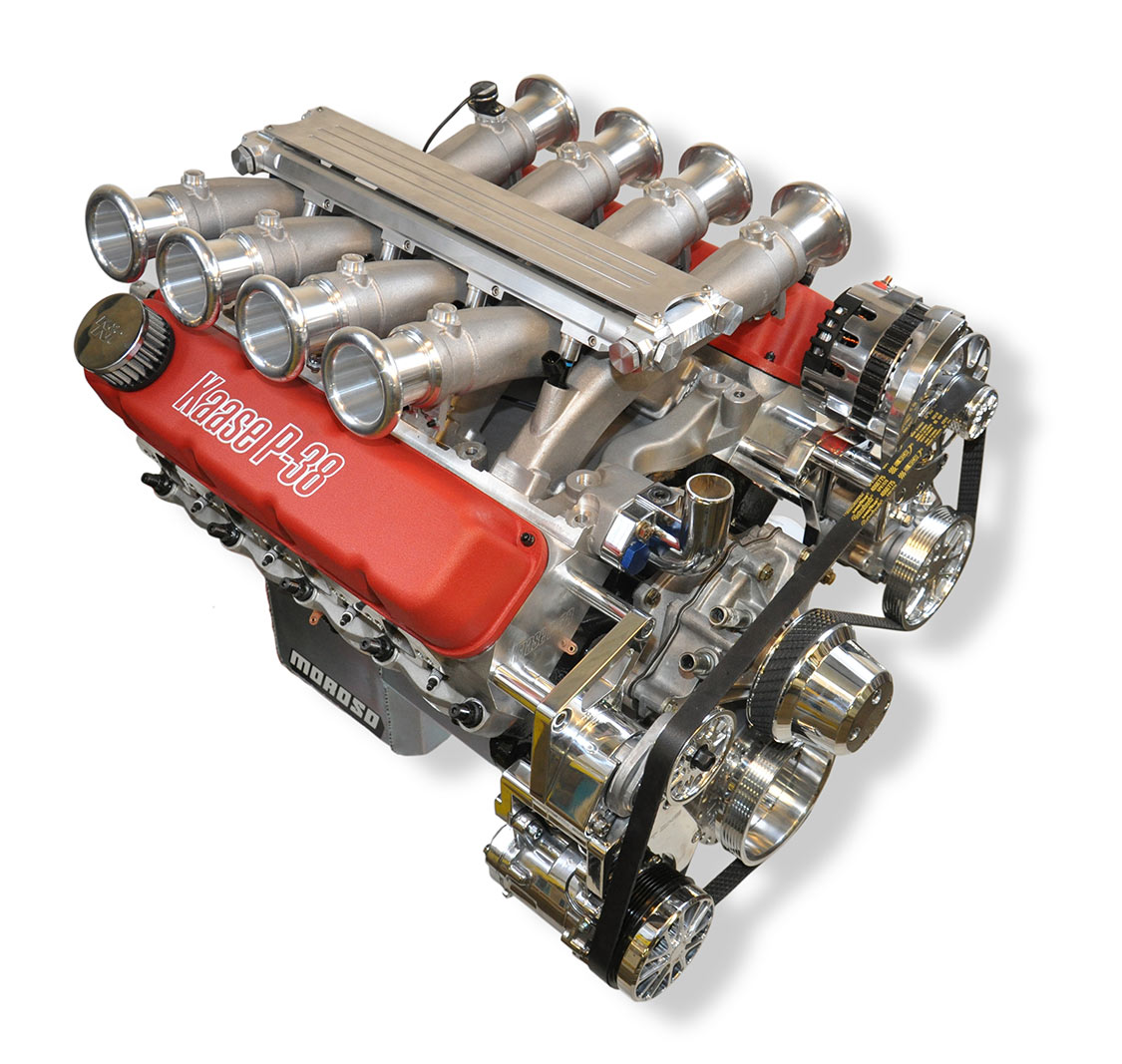

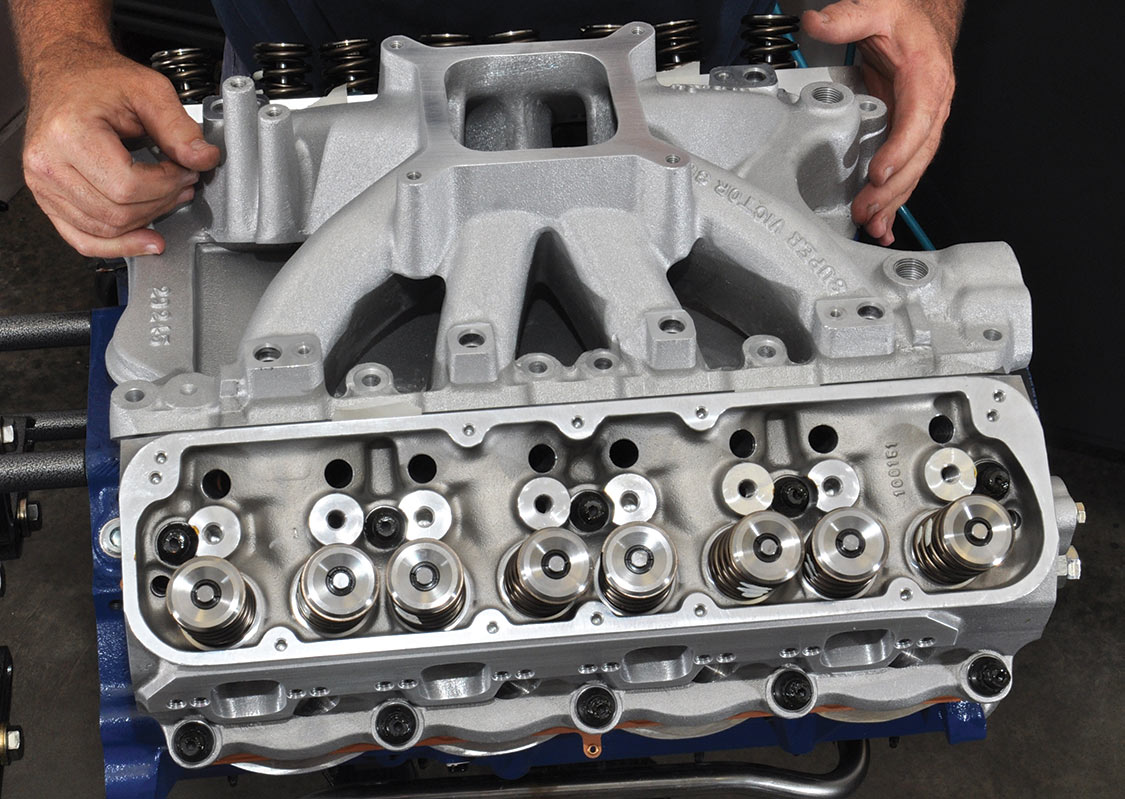

Engine philosopher Jon Kaase of Jon Kaase Racing Engines in Winder, Georgia had one of those nagging ideas. You know the type; the ones that make you look at something and say “why not?” For years he watched the ubiquitous Ford 302 market amass part upon improved part, but observed nary a deviation from the original cylinder head configuration. He thought he could produce cylinder head castings that looked like an ordinary Windsor 302/351 on the outside but inside would perform entirely different from the original blueprint. Being a racer, he knew the value of stealth. But more importantly, as an engine builder he knew the prime advantage of canting the valves to open towards the center of the cylinder, thus mitigating the natural shrouding effect of the cylinder wall.

The Ford P38 cylinder head was designed primarily for the 302W (8.2-inch deck height, 4×3 bore/stroke, 5.095-inch rods). It’s derivative of the popular 347-ci (over bored by .030-inch and stroke increased to 3.400-inch), the 351W (9.5-inch deck height, 4×3.5 bore/stroke, 5.960-inch rods) and the 427-454W Sportsman-type Dart block (9.5-inch deck height with 2.750-inch Cleveland main journals). Combustion chamber volume is typically 60-62cc.

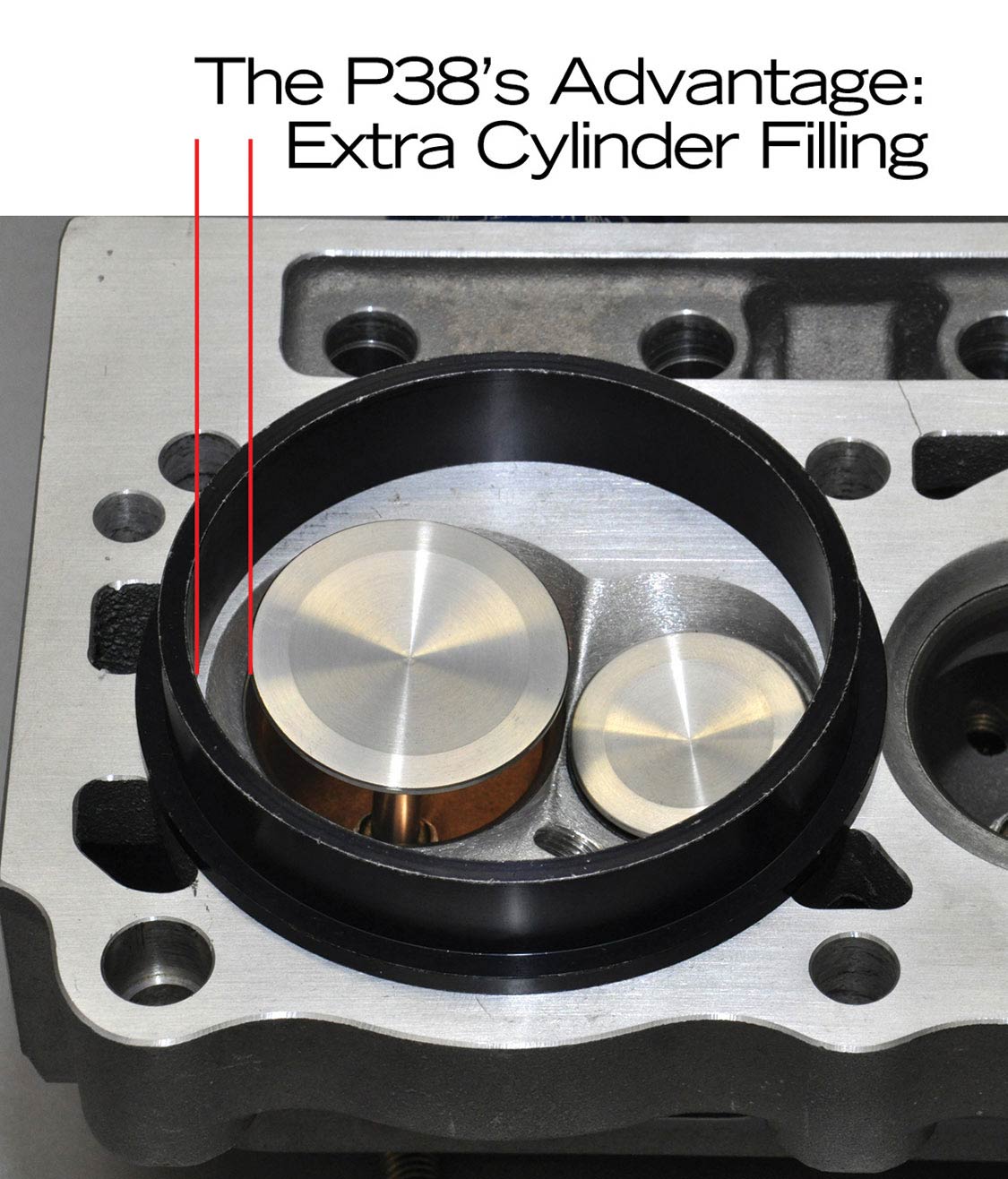

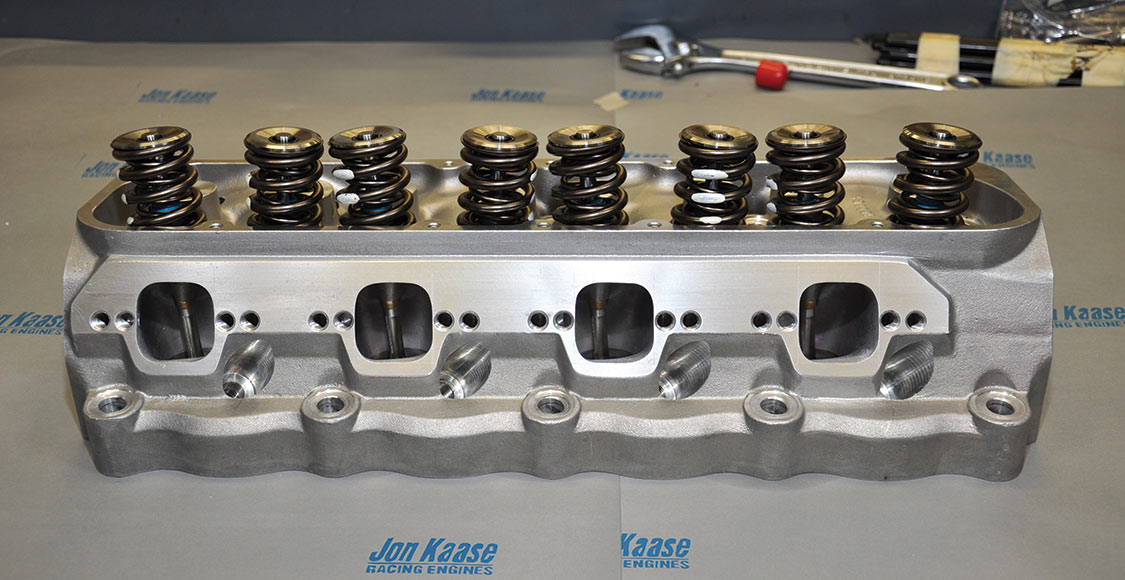

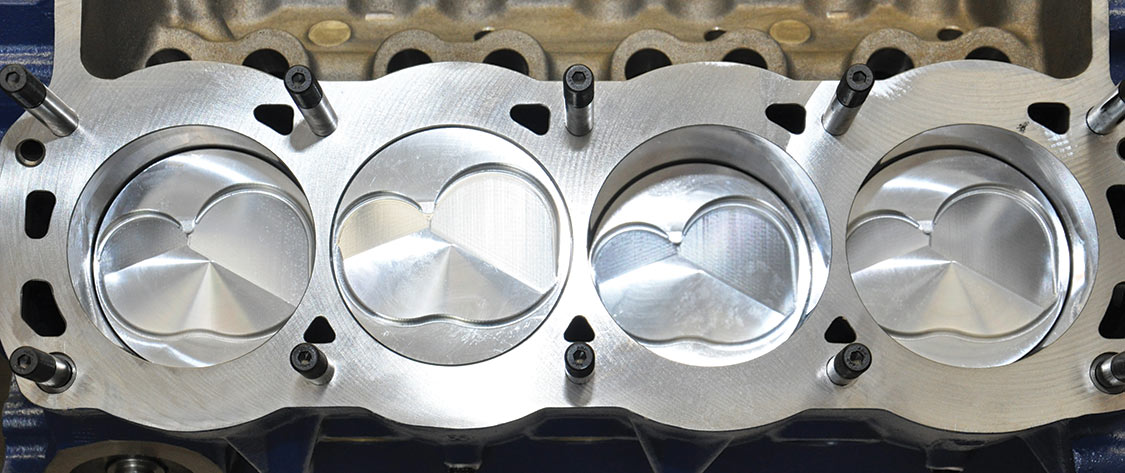

For better cylinder filling, Kaase envisioned valves canted at 8×4.5 degrees on the intake and 10×4 degrees for the exhaust. The new territory produced by this modification would allow him to increase the diameter of the valve heads to 2.100 inches and 1.60 inches and by astute CNC porting he would induce far superior airflow and cylinder filling compared with any conventional layout. The revised angles advantageously place the intake valve in the cylinder bore and the CNC porting is much more efficient than the original. It also has the qualities of a sweeping short-turn radius (on the floor of the port) and deeper valve bowls, giving the atomized fuel improved entry to the combustion chamber.

Assume a 2.100-inch intake valve yields 350 cfm in a port with a given cross-sectional area. Then assume that you increase valve size to 2.200 and the engine yields 360 cfm; the result could actually indicate a loss in performance. Such is the consequence of increasing the intake port and losing the air velocity because the opening is now larger. Sophisticated petrol heads know it doesn’t pay to increase cfm unless there is a simultaneous gain in airspeed.

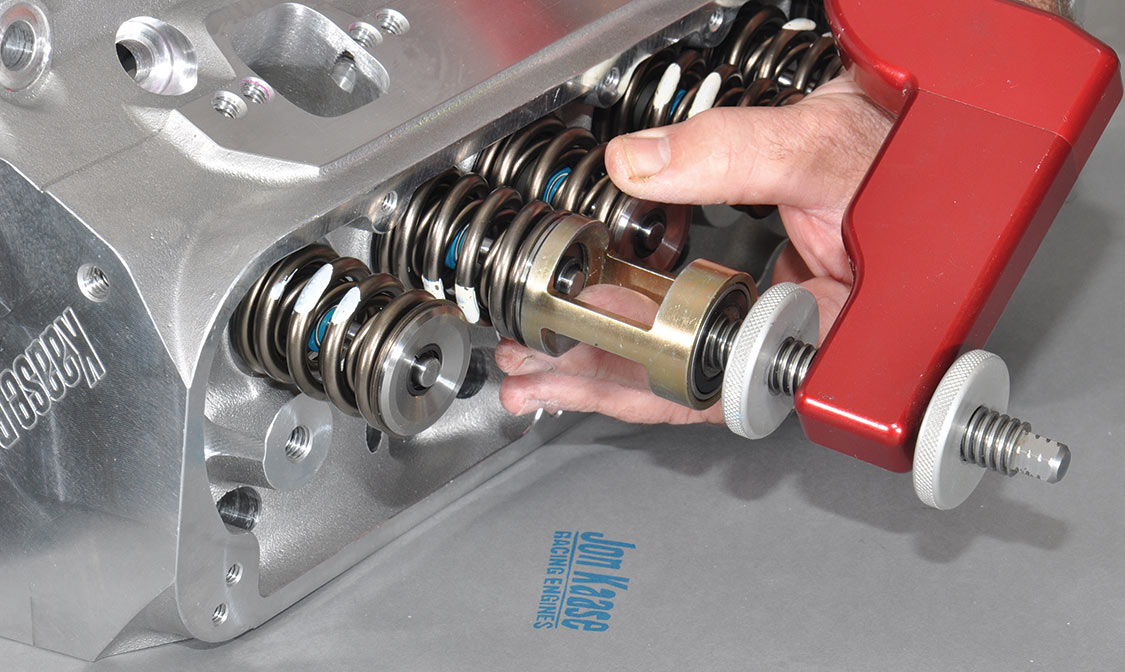

Then, because the P38s flow so well at 0.400-0.500 inch of valve lift, the camshaft could be tailored with 5 to 10 degrees less duration. This usually results in smoother idle and better low-end manners. These Kaase heads favor camshafts with close lobe centers that tend to produce more power.

The revised angles advantageously place the Intake valve in the cylinder bore and the cnc porting is much more efficient than the original.

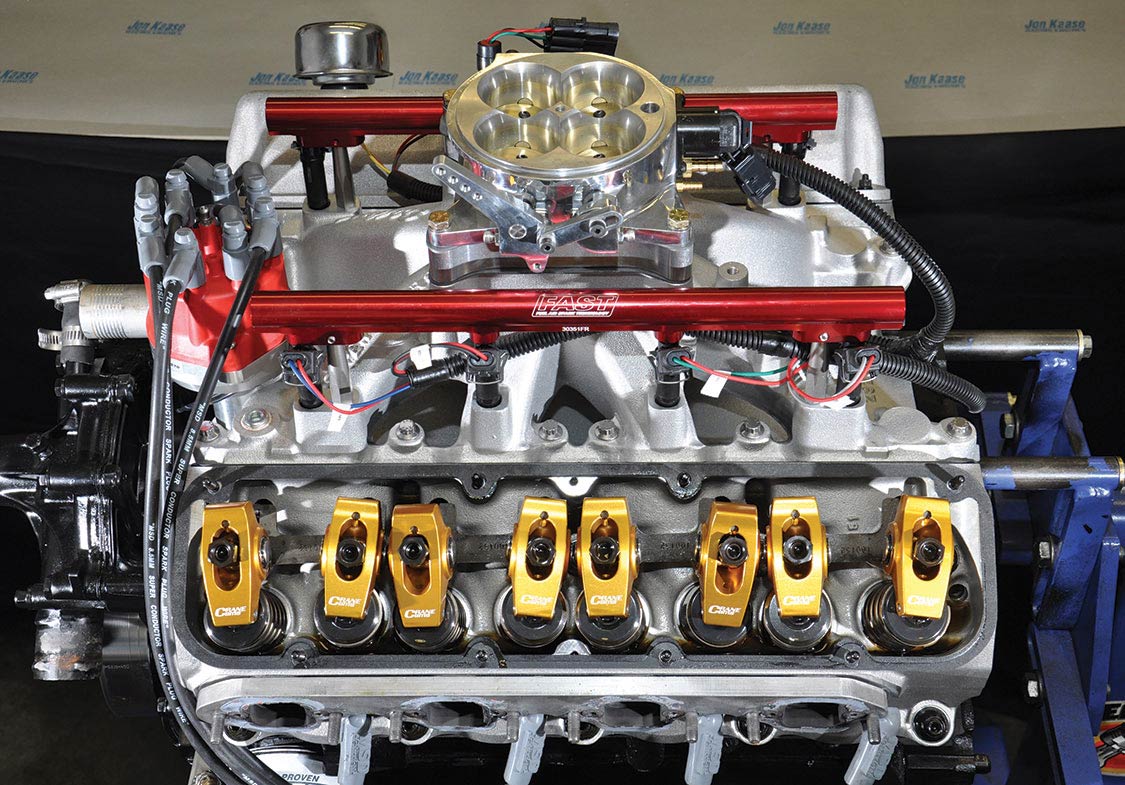

Though the 351 Cleveland could be coerced, its coolant flows through the front of the block and into the cylinder heads. With the Windsor, coolant flows through the intake manifold. Certainly the Cleveland’s redundant passages could be blocked off, but Kaase’s wisdom is to use the Windsor block that is stronger, readily available and requires no modification.

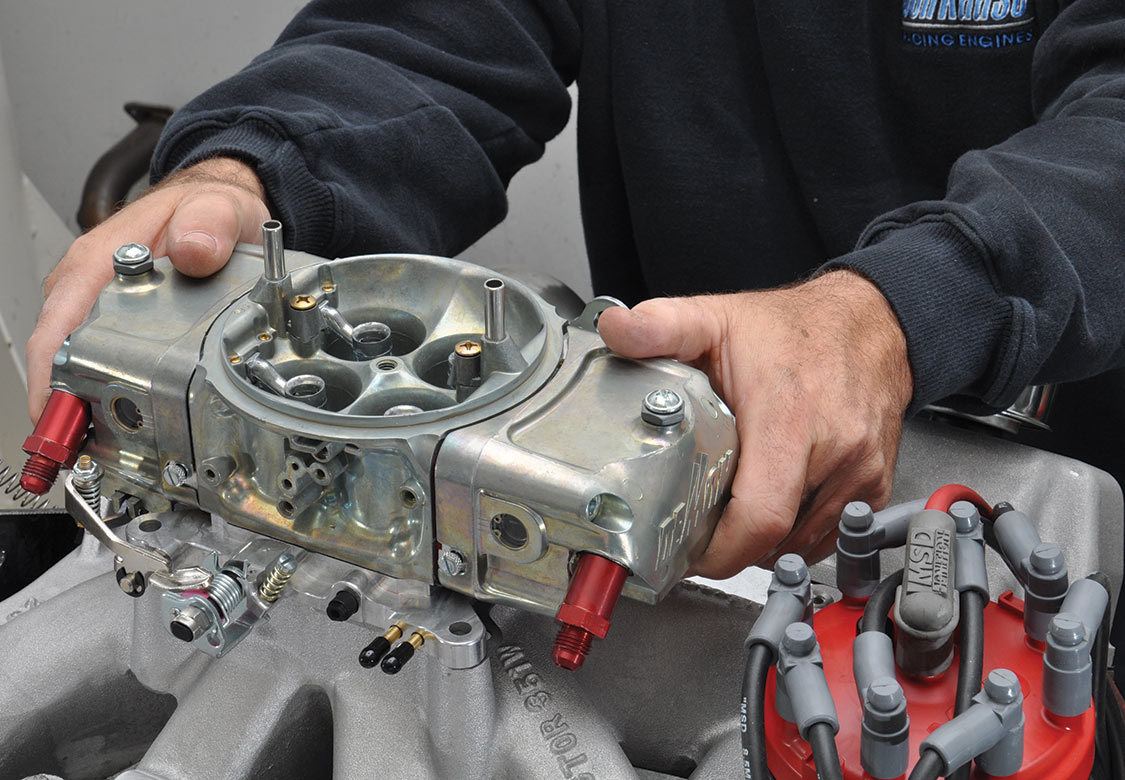

On pump gas and with barely 9.0:1 compression ratio, a modest mechanical roller camshaft and an Edelbrock Victor Jr. intake manifold, the Kaase 302 easily produces 500 hp at around 7,500 rpm. At the other end of the power spectrum, a Kaase-equipped 392-ci OE cylinder block belts out 650 hp all day long but is fully capable of producing 700 hp and beyond if desired.

Including valve covers and valve cover gaskets, the P38 heads are supplied with larger valves, springs, seals, retainers, rocker studs and guide plates installed. Complete P38 engines are also prepared at Kaase’s facility. These are accompanied with dynamometer test results and often a video. Dyno tests ensure the engine is producing the expected power output and is free of oil and water leaks.

The bottom line is a Ford 302 or 351 Windsor with much improved throttle response and more usable power. It also allows the Windsor to be competitive with far more expensive modified Cleveland engines. One more thing, Kaase’s annoying, nagging feeling is a thing of the past.

Jon Kaase Racing Engines

770.307.0241

Jonkaaseracingengines.com

Share Link